Mastering the Art of Welding

As an experienced welder and metal fabricator, I can attest to the immense satisfaction that comes from transforming raw materials into functional, high-quality products. The art of welding is not just about joining pieces of metal – it’s about precision, skill, and an unwavering commitment to excellence.

When I first started this journey, I was captivated by the sheer power and control required to wield a welding torch. The dance between the molten metal, the filler material, and the protective gas is a delicate ballet that requires years of practice to perfect. But let me tell you, once you’ve mastered the techniques, the sense of accomplishment is unparalleled.

One of the key elements in exceptional metal fabrication is the ability to control the heat input during the welding process. This is where the true artistry comes into play. Too much heat can distort the metal, while too little can result in incomplete fusion and weak joints. It’s a balancing act that requires a keen eye, a steady hand, and a deep understanding of the materials you’re working with.

In my experience, the best welders are those who have a holistic understanding of the entire fabrication process. They don’t just focus on the welding itself, but on the entire workflow – from initial design to final assembly. This allows them to anticipate potential challenges and make informed decisions that optimize the overall quality and efficiency of the project.

Embracing the Precision of Metal Fabrication

Precision is the lifeblood of metal fabrication. Whether you’re creating a intricate architectural piece or a rugged industrial component, the level of accuracy required is often astounding. I’ve spent countless hours carefully measuring, marking, and cutting materials to ensure that every component fits together seamlessly.

One of the techniques I’ve become particularly adept at is the use of jigs and fixtures. These specialized tools help to maintain proper alignment and positioning during the welding process, ensuring that the final product meets the strictest tolerances. It’s a meticulous process, but the results speak for themselves – perfectly aligned seams, uniform bead profiles, and a finished product that looks and performs flawlessly.

But precision isn’t just about the physical characteristics of the fabricated components. It’s also about the attention to detail in every aspect of the workflow. From the initial design stage to the final quality control checks, I make sure that every step is carried out with the utmost care and diligence. This attention to detail is what sets the truly exceptional fabricators apart from the rest.

Embracing the Latest Welding and Fabrication Technologies

The world of welding and metal fabrication is constantly evolving, with new technologies and techniques emerging all the time. As a seasoned professional, I’ve made it a priority to stay on the cutting edge, continuously learning and adapting to ensure that I’m delivering the best possible solutions for my clients.

One area that has seen significant advancements in recent years is the realm of welding automation. The integration of robotic welding systems has revolutionized the way we approach large-scale fabrication projects. These automated systems not only improve consistency and repeatability, but they also drastically reduce the risk of human error. And let me tell you, the level of precision and efficiency they can achieve is simply awe-inspiring.

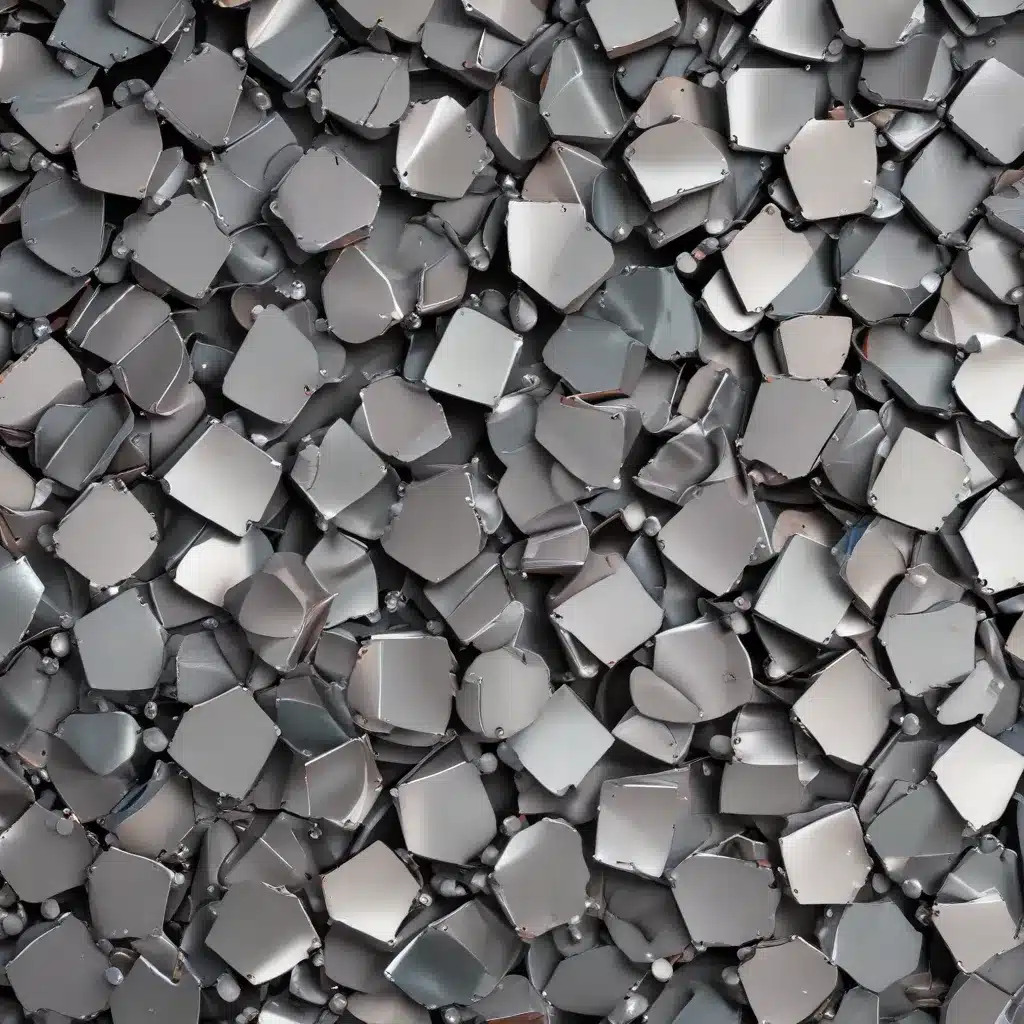

But automation isn’t the only game-changer in our industry. The development of advanced welding consumables, such as specialty filler materials and shielding gases, has also had a profound impact on the quality and performance of our finished products. By carefully selecting the right consumables for the job, we can optimize weld properties, reduce distortion, and enhance the overall durability of the fabricated components.

Fostering a Culture of Continuous Improvement

In the world of metal fabrication, complacency is the enemy. That’s why I’ve made it a point to constantly challenge myself and my team to find new ways to elevate our craft. Whether it’s experimenting with different welding techniques, exploring innovative fabrication methods, or simply refining our existing processes, we’re always striving to push the boundaries of what’s possible.

One of the ways we’ve achieved this is through a robust quality assurance program. We’ve implemented rigorous inspection and testing protocols, ensuring that every step of the fabrication process is thoroughly evaluated and validated. This not only helps us identify and address any issues before they become major problems, but it also provides us with valuable data that we can use to continually improve our workflows.

But it’s not just about the technical aspects of our work – it’s also about fostering a culture of collaboration and continuous learning. I make it a point to encourage my team to share their ideas, ask questions, and challenge the status quo. After all, some of our most innovative solutions have come from the fresh perspectives and unique insights of our dedicated fabricators.

Delivering Exceptional Results for Our Clients

At the end of the day, the true measure of our success as metal fabricators is the satisfaction of our clients. And I can say with absolute certainty that there’s nothing quite like the feeling of handing over a finished project that exceeds our customers’ expectations.

Whether it’s a custom-built piece of machinery, a towering architectural installation, or a critical industrial component, the pride and joy I experience in delivering exceptional results is truly unmatched. I love seeing the look of awe and appreciation on our clients’ faces as they behold the fruits of our labor – a testament to the skill, dedication, and craftsmanship that went into every step of the process.

But it’s not just about the final product. It’s also about the journey we take with our clients, the collaborative problem-solving, and the shared sense of accomplishment when we overcome the inevitable challenges that arise. By fostering strong partnerships and open communication, we’re able to create truly remarkable solutions that not only meet our clients’ needs but also exceed their wildest dreams.

Conclusion

As I reflect on my career as a welder and metal fabricator, I’m struck by the incredible depth and complexity of our craft. It’s not just about wielding a welding torch or manipulating metal – it’s about a relentless pursuit of perfection, a deep understanding of materials and processes, and an unwavering commitment to quality.

In a world that is constantly evolving, the role of the metal fabricator has never been more crucial. We are the artisans, the innovators, the problem-solvers who bring life to the designs and visions of architects, engineers, and industry leaders. And it is our responsibility to continue pushing the boundaries of what’s possible, to embrace the latest technologies, and to uphold the highest standards of precision and excellence.

So, if you’re a fellow welder or metal fabricator, take pride in the work you do. Embrace the challenge, hone your skills, and never stop striving for perfection. And if you’re a client in need of exceptional metalworking solutions, look no further than The Weld Fab – where precision craftsmanship and unparalleled expertise come together to create truly remarkable results.