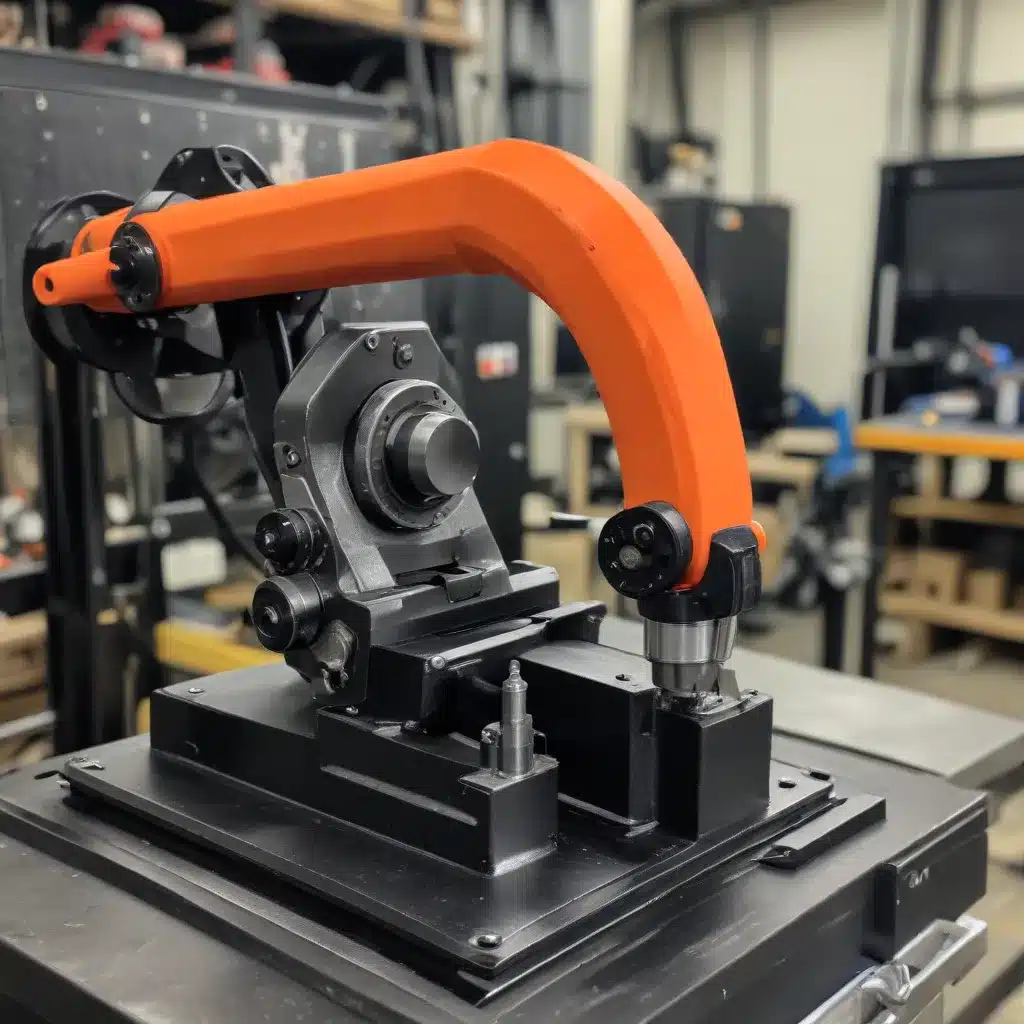

As an experienced welder and metal fabricator, I’ve seen firsthand how advancements in technology have revolutionized our industry. One of the most exciting innovations that has truly transformed the way we work is the emergence of 3D printed welding positioners. These customizable tools have not only improved our ergonomics and safety but have also boosted productivity and profitability in ways I never thought possible.

Goodbye to Strain and Fatigue: The Ergonomic Advantage

When I first started in this field, I remember the constant strain and discomfort that came with the job. Hours spent hunched over, contorting our bodies to reach difficult angles, and constantly repositioning heavy parts – it was a recipe for burnout and injury. But now, with the help of these innovative 3D printed positioners, the game has completely changed.

These positioners allow us to adjust the angle, height, and rotation of the workpiece with the simple push of a button. No more struggling to lift and maneuver huge components into the perfect position. Instead, we can easily manipulate the setup to suit our ergonomic needs, reducing strain on our backs, necks, and shoulders. I can’t tell you how many times these positioners have saved me from a debilitating injury.

And it’s not just about physical comfort – the improved ergonomics also translate to enhanced productivity. When our bodies are properly supported and positioned, we can focus more on the task at hand, rather than fighting against the limitations of our equipment. I’ve noticed a significant increase in my welding speed and accuracy, which has directly impacted the quality of our finished products.

Customized Perfection: The Power of 3D Printing

One of the most remarkable aspects of these 3D printed positioners is their ability to be tailored to each individual welder’s needs. Gone are the days of trying to make do with a one-size-fits-all solution. Now, we can work with the engineers to design and fabricate positioners that perfectly match our body types, work preferences, and the specific demands of each project.

I’ll never forget the time we were tasked with welding a series of intricate components for a high-profile aerospace client. The parts were oddly shaped and required precise positioning to ensure the welds were flawless. With a traditional positioner, we would have struggled to find the right setup, but with our 3D printed solution, we were able to create a custom jig that held everything in place with pinpoint accuracy.

The level of customization is truly astounding. We can adjust the height, angle, and rotation to accommodate our individual statures and preferences. Some welders prefer a more upright position, while others like to be closer to the work. With 3D printing, we can accommodate those nuanced needs without compromising performance.

Boosting Productivity and Profitability

Of course, the benefits of these 3D printed positioners go beyond just ergonomics and comfort. They’ve also had a significant impact on our overall productivity and profitability as a fabrication shop.

With the improved positioning and stability provided by these tools, we’ve seen a noticeable reduction in material waste and rework. Gone are the days of misaligned parts or poorly executed welds that require extensive grinding and refinishing. Now, we can get the job done right the first time, every time.

And the time savings are staggering. Rather than spending valuable minutes (or even hours) carefully maneuvering heavy components into the perfect position, we can simply adjust the positioner and get to work. This streamlined process has allowed us to take on more projects, complete them faster, and ultimately deliver greater value to our customers.

But the benefits don’t stop there. The increased productivity and efficiency have also had a direct impact on our bottom line. By reducing labor costs, material waste, and rework, we’ve been able to offer more competitive pricing without sacrificing our profit margins. It’s a win-win for both us and our clients.

Safety First: Protecting Our Most Valuable Assets

Of course, as welders and fabricators, safety is always our top priority. And these 3D printed positioners have played a crucial role in enhancing the safety of our operations.

By minimizing the physical strain and fatigue associated with the job, we’ve seen a significant reduction in workplace injuries and lost time. No more painful back spasms or debilitating muscle strains – our team is healthier, happier, and more focused on the task at hand.

But it’s not just about our personal well-being. These positioners also help to protect our most valuable assets – our skilled welders and fabricators. In an industry that already faces a concerning labor shortage, we can’t afford to lose experienced professionals to preventable injuries. By investing in these ergonomic solutions, we’re not only safeguarding our employees but also ensuring the long-term viability and success of our business.

Adapting to a Changing Landscape

As with any technological advancement, the integration of 3D printed positioners has required a certain level of adaptation and skill development. But I can assure you, the learning curve is well worth the rewards.

Sure, we’ve had to familiarize ourselves with the operation and programming of these sophisticated tools, but the benefits far outweigh the initial adjustment period. And with the help of virtual reality (VR) training and augmented reality (AR) guidance, the transition has been remarkably smooth.

In fact, I’d argue that these new technologies have opened up a whole new world of possibilities for welders and fabricators. VR simulations allow us to practice complex techniques in a controlled environment, without the risk of damaging equipment or injuring ourselves. And AR overlays provide real-time instructions and feedback, helping us to refine our skills and ensure flawless execution on the job site.

It’s an exciting time to be in this industry, and I’m proud to be at the forefront of these technological advancements. As we continue to embrace innovation and adapt to the changing landscape, I’m confident that welding and fabrication will only become safer, more efficient, and more rewarding for everyone involved.

Embracing the Future of Welding and Fabrication

As I reflect on my journey in this industry, I can’t help but feel a deep sense of pride and excitement for the future. The introduction of 3D printed welding positioners has not only transformed the way we work but has also opened up a world of new possibilities.

Gone are the days of struggling with cumbersome equipment and enduring debilitating injuries. Now, we can focus on what we do best – creating exceptional, precision-engineered metalworks that push the boundaries of what’s possible.

And as we continue to explore the endless potential of technologies like VR, AR, and collaborative robotics, I can’t wait to see what the future holds. I know that the welding and fabrication industry is poised for a revolution, and I’m honored to be a part of it.

So, if you’re a fellow welder or fabricator, I encourage you to embrace these advancements with open arms. Dive in, experiment, and let your creativity and skills shine. After all, the quality of our work is a testament to our passion, our precision, and our unwavering commitment to perfection.

At the end of the day, we’re not just welders and fabricators – we’re artists, engineers, and problem-solvers, all working together to push the boundaries of what’s possible. And with the help of these remarkable 3D printed positioners, I know that the future of our industry has never been brighter.