As an experienced welder and metal fabricator, I’ve had the privilege of working with a wide range of welding techniques over the years. From the classic arc welding methods to the more advanced laser and electron beam processes, I’ve seen it all. But one technique that has truly captivated me is the art of friction stir welding. This innovative approach to joining metals has revolutionized the way we think about fabrication, and I’m excited to share my insights and personal experiences with you.

The Beauty of Friction Stir Welding

Imagine a world where you can seamlessly fuse two pieces of metal without the need for intense heat or the constant worry of warping or distortion. That’s the beauty of friction stir welding. Unlike traditional welding techniques that rely on melting the base material, this process harnesses the power of friction to create a solid-state bond.

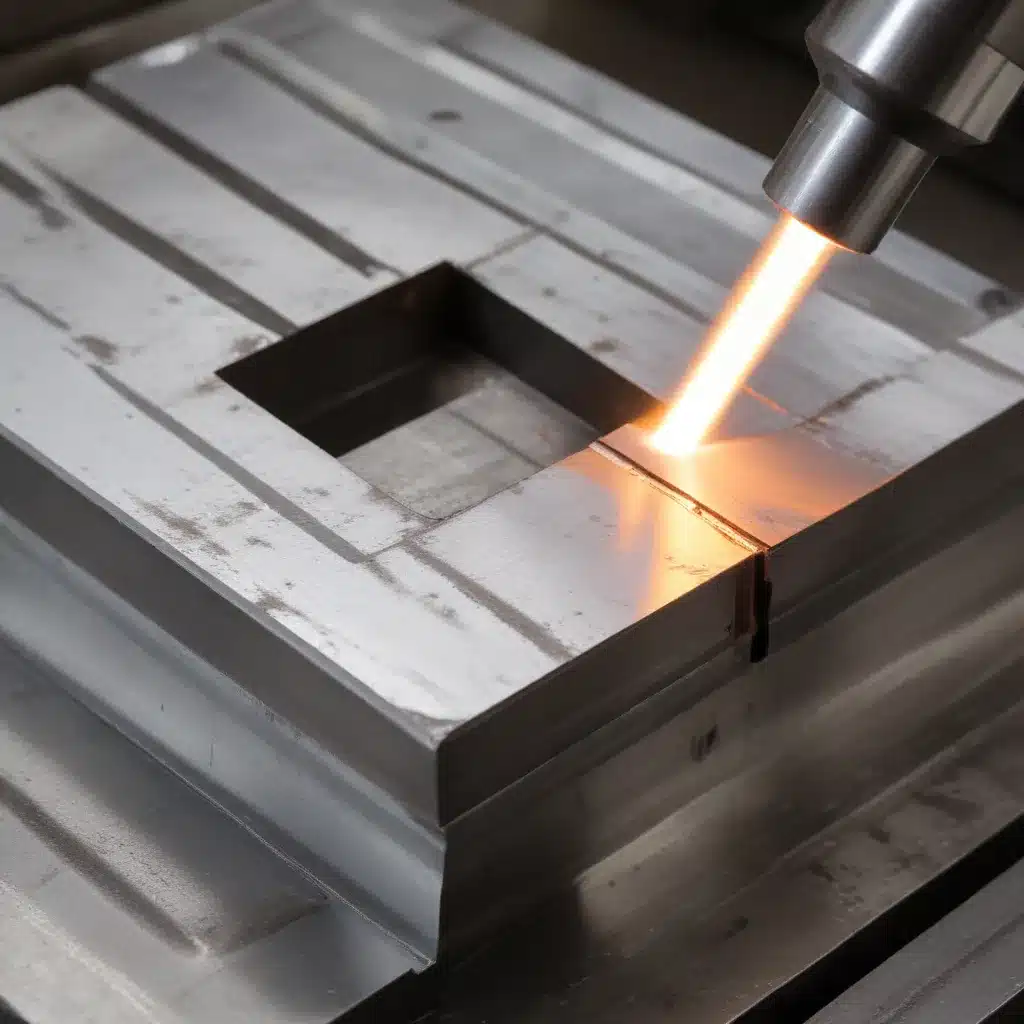

Picture a spinning tool, almost like a sophisticated drill bit, that plunges into the joint between the two metal pieces. As the tool rotates, it generates heat through friction, softening the material without actually melting it. The tool then traverses the joint, stirring and intermixing the metal, forging a strong, cohesive bond.

The result? A weld that is not only visually appealing, with a smooth, consistent appearance, but also incredibly strong and durable. The lack of melting means there’s no heat-affected zone, reducing the risk of distortion, cracking, or residual stresses – issues that can plague other welding methods.

The Magic of Friction Stir Welding

As a welder, I’ve always been fascinated by the science behind the processes I use. Friction stir welding is no exception. The underlying mechanics of this technique are truly remarkable, and understanding them has helped me hone my skills and achieve exceptional results.

The key to the magic of friction stir welding lies in the way the tool interacts with the metal. The rotating motion creates a localized zone of intense plastic deformation, where the metal is essentially “stirred” and mixed at the atomic level. This stirring action disrupts the natural grain structure of the material, creating a fine-grained, homogeneous joint that is often stronger than the base metal itself.

But the real genius of friction stir welding lies in its ability to join dissimilar metals – something that can be incredibly challenging with traditional welding methods. The solid-state nature of the process allows for the seamless integration of materials like aluminum, steel, and even titanium, opening up a world of possibilities for fabricators.

Precision and Consistency: The Hallmarks of Friction Stir Welding

As a skilled welder, I’ve always prided myself on my attention to detail and the pursuit of perfection. Friction stir welding aligns perfectly with this philosophy, as it demands a level of precision and consistency that is simply unmatched by other joining techniques.

The success of a friction stir weld is largely dependent on the careful control of a multitude of parameters, including tool speed, downward force, and traverse rate. Get these just right, and you’re rewarded with a flawless, defect-free joint. But let even one factor slip, and the entire weld can be compromised.

That’s why I take such a meticulous approach to every friction stir welding project. I meticulously monitor and adjust the process variables, ensuring that every inch of the weld is executed with the utmost care. The result? Joints that are not only visually stunning, but also possess unparalleled strength and reliability.

Tackling the Challenges of Friction Stir Welding

Of course, with any advanced welding technique, there are always challenges to overcome. Friction stir welding is no exception, and as a seasoned fabricator, I’ve had my fair share of experiences navigating these hurdles.

One of the primary challenges lies in the selection of the right tool material and design. The tool must be able to withstand the intense heat and forces generated during the welding process, all while maintaining a precise shape to ensure consistent weld quality. I’ve spent countless hours experimenting with different tool geometries and materials, constantly refining my approach to achieve the best results.

Another challenge is the need for a robust clamping system to hold the workpieces in place during welding. Traditional welding often relies on the molten metal to fill in any gaps or inconsistencies, but with friction stir welding, maintaining a tight, secure fit between the parts is crucial. I’ve developed custom clamping solutions that ensure perfect alignment and prevent any unwanted movement during the process.

But perhaps the biggest challenge I’ve faced is the need to adapt my welding technique to the specific materials and applications at hand. Aluminum, for instance, requires a different approach than steel, and the thickness of the workpieces can also play a significant role. It’s a constant balancing act, but one that I’ve come to relish as I strive to push the boundaries of what’s possible with friction stir welding.

The Versatility of Friction Stir Welding

One of the things I love most about friction stir welding is its incredible versatility. This technique can be applied to a wide range of industries, from aerospace and automotive to shipbuilding and heavy equipment manufacturing.

In the aerospace sector, for example, friction stir welding has become a game-changer. The ability to seamlessly join lightweight materials like aluminum alloys has allowed for the creation of stronger, more fuel-efficient aircraft structures. I’ve had the privilege of working on projects where the smooth, consistent welds produced by friction stir welding have been crucial in meeting the stringent performance and safety requirements of the aviation industry.

Similarly, in the automotive world, friction stir welding has revolutionized the way we approach vehicle body and chassis assembly. By eliminating the need for heavy fasteners and the associated thermal distortion, this technique has enabled the production of lighter, more streamlined vehicles that offer improved fuel efficiency and handling.

But the versatility of friction stir welding extends far beyond these high-profile industries. I’ve used this technique to tackle a wide range of fabrication challenges, from the construction of industrial machinery to the repair of critical infrastructure components. The consistency and reliability of the welds have consistently proven to be a game-changer, regardless of the application.

The Weld Fab Advantage: Mastering Friction Stir Welding

At The Weld Fab, we take great pride in our ability to push the boundaries of what’s possible in the world of metal fabrication. And when it comes to friction stir welding, we’ve truly honed our craft to a level of unparalleled excellence.

Our team of seasoned welders and fabricators has spent countless hours perfecting our techniques, experimenting with different tools and parameters to achieve the best possible results. We’ve developed custom clamping solutions, optimized our tool selection, and fine-tuned our process controls to ensure that every friction stir weld we produce is a work of art.

But it’s not just about the technical mastery – it’s about the passion and attention to detail that we bring to every project. We understand that the success of a fabrication job often hinges on the quality of the welds, and we’re driven to deliver nothing less than perfection.

Whether you’re working on a high-profile aerospace project or a critical infrastructure repair, you can trust that The Weld Fab team will bring our unrivaled expertise in friction stir welding to the table. We’ll collaborate closely with you to understand your unique requirements, and then leverage our vast experience to develop a customized solution that exceeds your expectations.

The Future of Friction Stir Welding

As we look to the future, I’m excited to see how the world of friction stir welding will continue to evolve. With ongoing advancements in materials science, automation, and process control, I believe we’re only scratching the surface of what’s possible with this revolutionary joining technique.

Imagine a future where even the most complex, dissimilar metal assemblies can be seamlessly and effortlessly fabricated, with welds that are indistinguishable from the surrounding materials. Or picture a world where robots and computer-controlled systems can execute friction stir welds with unparalleled precision, opening up new horizons in high-volume, high-quality manufacturing.

And as an experienced welder, I can’t help but wonder how the continued evolution of friction stir welding will impact the very nature of my craft. Will the need for skilled manual welders diminish, or will our role simply shift to one of oversight and process optimization? These are the kinds of questions that keep me up at night, constantly pushing me to stay ahead of the curve and adapt to the changing landscape of the industry.

One thing is certain: no matter what the future holds, the team at The Weld Fab will be at the forefront of the friction stir welding revolution. We’re committed to staying on the cutting edge of this technology, continuously refining our techniques and expanding the boundaries of what’s possible. And we’ll be here to guide our clients every step of the way, helping them navigate the exciting opportunities that lie ahead.

So, if you’re ready to experience the magic of friction stir welding and unlock a whole new world of fabrication possibilities, I invite you to join us on this journey. Together, we’ll push the limits of what’s achievable and redefine the very nature of metal joining. After all, at The Weld Fab, we don’t just weld – we create works of art that stand the test of time.