Unlocking the Power of Collaborative Robotics in Fabrication

As an experienced welder and metal fabricator, I’ve seen firsthand how the industry has evolved over the years. From the days of manual welding to the rise of automation, the world of metalworking has undergone a remarkable transformation. And at the forefront of this revolution are the collaborative robots, or cobots, that are reshaping the way we approach our craft.

When I first started in this field, I’ll admit, I was a bit skeptical about automation. After all, welding has always been such a hands-on, skill-intensive process. How could a robot possibly replicate the precision and finesse that we seasoned welders had honed over the years? Well, let me tell you, my friends, the cobots of today have proved me wrong in the most delightful way.

Cobots: Bridging the Gap Between Automation and Flexibility

One of the biggest challenges we’ve faced in the fabrication industry has been balancing the need for automation with the ever-changing demands of our customers. Traditional industrial robots, while incredibly efficient, were often too rigid and complex to adapt to the high-mix, low-volume work that’s become the norm in our shops.

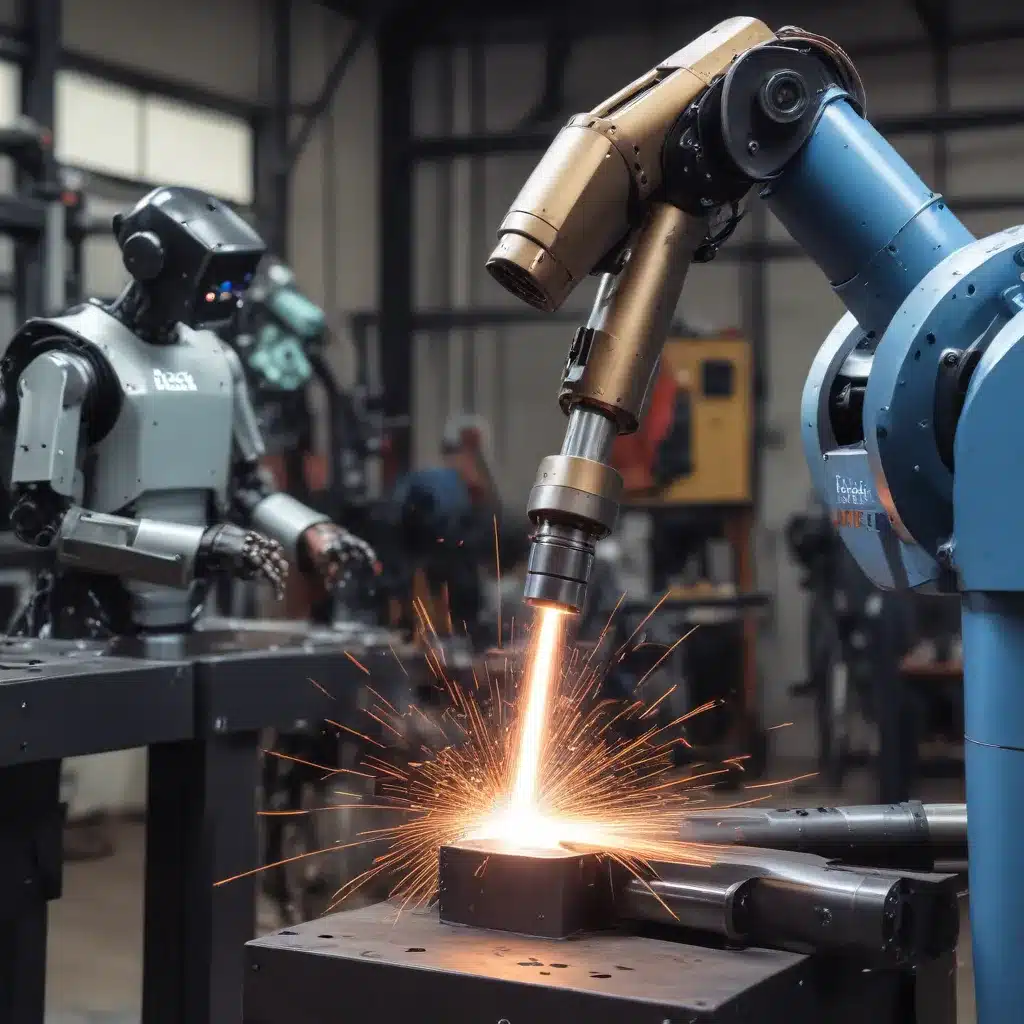

Enter the cobot – a game-changer in the world of welding automation. These collaborative robots are designed to work alongside our skilled welders, rather than replacing them entirely. They offer a level of flexibility that simply wasn’t possible with their industrial counterparts.

I’ll never forget the day we brought in our first cobot welder. It was a bit of a gamble, I’ll admit, but the potential benefits were too tempting to ignore. And let me tell you, the results have been nothing short of astounding.

Precision, Consistency, and Speed: Cobot Welding at Its Finest

One of the most striking advantages of cobot welding is the incredible precision and consistency it brings to the table. Gone are the days of worrying about uneven weld beads or inconsistent penetration. With the cobots, each weld is executed with surgical precision, every single time.

I remember working on a particularly intricate aluminum component a few months back. Normally, this would have been a real challenge, requiring countless hours of careful TIG welding by hand. But with our cobot welder, we were able to knock out those welds in a fraction of the time, with flawless results.

And the speed – oh, the speed! Our cobot welders have quite literally doubled our productivity on certain parts. What used to take 15 minutes per weld is now down to a blistering 5 or 6 minutes. And the best part? The quality hasn’t suffered one bit. In fact, I’d argue it’s even better than what we could achieve manually.

Versatility and Adaptability: Cobots at the Forefront of Fabrication

But the real beauty of these cobots lies in their sheer versatility. One day, they’re cranking out perfectly uniform MIG welds on steel parts. The next, they’re tackling the most intricate TIG welds on stainless or aluminum components. And the best part? The transition is seamless.

I remember when we first started exploring the idea of adding TIG welding capabilities to our cobot setup. The team at THG Automation, our integrator, assured us that it would be a breeze. And they weren’t kidding – within a matter of hours, we had that cobot set up and producing better TIG welds than some of our veteran welders.

The ability to switch between welding processes with ease has opened up a whole new world of possibilities for us. No longer are we pigeonholed into one type of fabrication or another. We can now tackle a wider range of projects, from the simple to the downright complex, all with the help of our trusty cobot welders.

Embracing the Future: Cobot Welding and the Evolving Metalworking Landscape

As I look around our shop, I can’t help but marvel at the transformation we’ve undergone. Gone are the days of endless manual welding, of constantly scrambling to find skilled labor. Now, our cobots work tirelessly alongside our welders, taking on the repetitive, monotonous tasks and freeing them up to focus on the more intricate, challenging projects.

And the best part? The learning curve for these cobots is hardly as steep as one might expect. With their intuitive, app-based programming interfaces, even our most seasoned welders were able to pick it up in a matter of hours. No more struggling with complex robotics software or extensive training – just plug and play, as they say.

But the real game-changer, in my opinion, is the way these cobots have transformed our customer relationships. No longer are we limited by the constraints of our manual welding capabilities. We can now take on larger orders, faster turnaround times, and more complex fabrication projects with ease. And our customers? They’re ecstatic.

Embracing the Future: Cobots as Industry Disruptors

As I reflect on the journey we’ve taken with our cobot welders, I can’t help but feel a sense of excitement for the future of our industry. These collaborative robots aren’t just tools – they’re disruptors, reshaping the way we approach metalworking and fabrication.

Think about it – no more struggling to find skilled welders, no more worrying about the quality and consistency of our welds, no more turning away projects that push the limits of our capabilities. With cobots in our corner, the possibilities are truly endless.

And it’s not just us, either. I’ve seen these robotic welders popping up in shops all across the country, transforming the way fabricators work and thrive. It’s an exciting time to be in this industry, my friends, and I for one can’t wait to see what the future holds.

Conclusion: Embracing the Cobot Revolution

So, if you’re a fellow welder or fabricator out there, considering taking the plunge into cobot automation, let me give you a piece of advice: do it. Trust me, the investment will pay off tenfold. These collaborative robots are the future of our industry, and the sooner you embrace them, the better prepared you’ll be to tackle the challenges and opportunities that lie ahead.

At the end of the day, it’s all about quality, efficiency, and customer satisfaction. And with cobots in your corner, you’ll be well on your way to delivering exceptional metalworking solutions that set you apart from the competition. So, what are you waiting for? Let’s dive into the cobot revolution together and take our fabrication game to new heights!