As an experienced welder and metal fabricator, I’ve learned that the key to building structures that can withstand the rigors of heavy use lies in the details of the welding process. One critical aspect that often separates superior craftsmanship from the average is the careful optimization of weld bead geometry.

In my years working in this industry, I’ve had the privilege of seeing firsthand how the subtle nuances of weld profile can dramatically impact the fatigue life of high-strength steel components. It’s a fascinating interplay between metallurgy, physics, and good old-fashioned technique – one that demands a deep understanding of the science behind welding, as well as the dexterity to execute it with precision.

The Science of Weld Bead Geometry

When it comes to welded structures, fatigue is often the primary concern. These components are subjected to repeated cycles of stress and strain, which can gradually accumulate damage and lead to catastrophic failure if not addressed. And as you’d expect, the weld areas are typically the most vulnerable points.

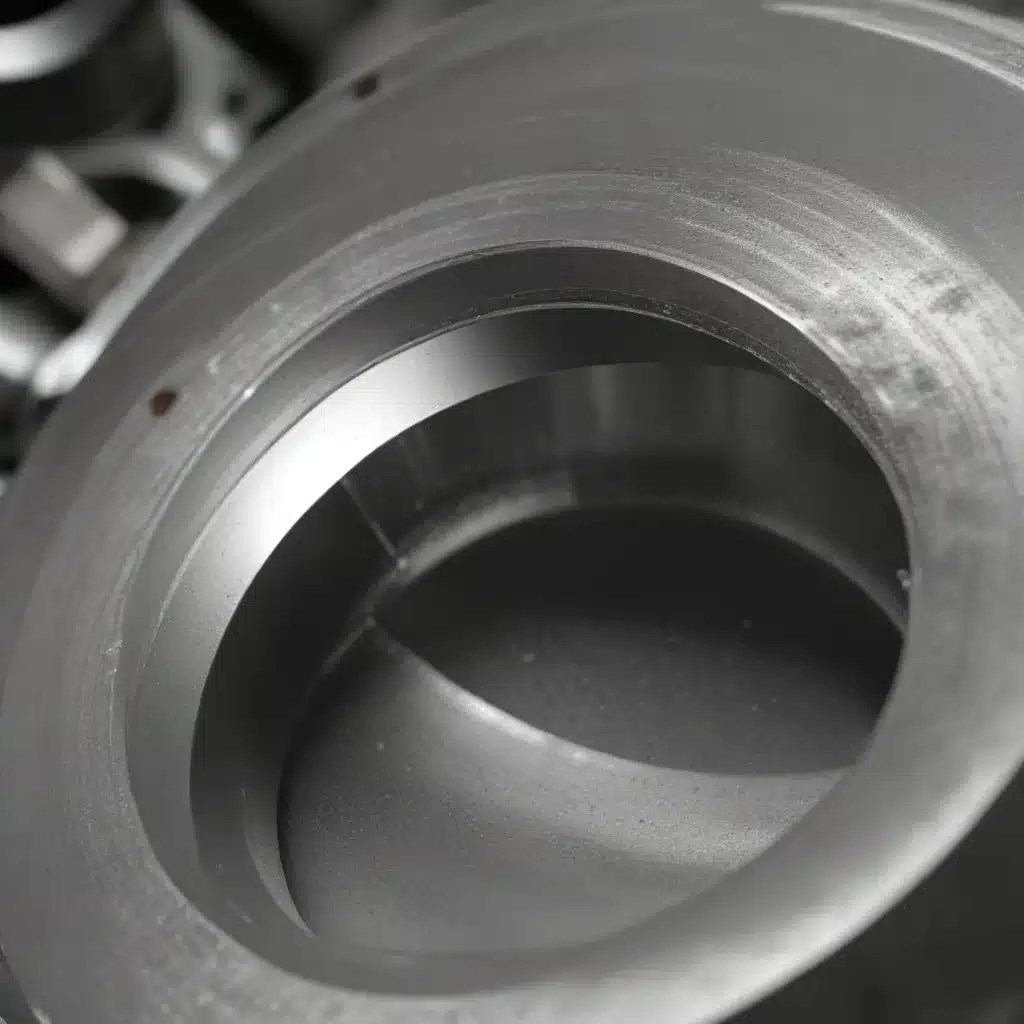

The shape and smoothness of the weld bead itself plays a crucial role in determining how well the joint will withstand fatigue loading. A weld with an abrupt, angular profile will create stress concentrations that accelerate crack initiation and propagation. On the other hand, a weld with a gradual, well-blended transition to the base material can significantly improve the component’s fatigue performance.

Techniques for Weld Bead Optimization

Over the years, welding professionals have developed various techniques to optimize weld bead geometry and enhance fatigue life. One approach that’s gained traction in recent decades is the use of low-transformation-temperature (LTT) welding consumables.

The idea behind LTT is to leverage the phase transformation of the weld metal to induce compressive residual stresses at the weld toe. As the molten weld pool cools and solidifies, the austenite-to-martensite transformation causes a volumetric expansion that counteracts the tensile stresses typically found in conventional welds. This helps create a smoother, more gradual transition between the weld and base material, improving the stress distribution and delaying the onset of fatigue cracking.

Another technique that’s proven highly effective is high-frequency mechanical impact (HFMI) treatment. This process involves using a high-frequency vibrating tool to mechanically “peen” the weld toe, causing localized plastic deformation and inducing beneficial compressive residual stresses. The improved weld toe geometry and residual stress state work in tandem to enhance the component’s fatigue strength.

Comparing Weld Bead Optimization Techniques

In a recent study on welded joints in a 1300 MPa yield strength steel, researchers set out to compare the effects of LTT consumables, HFMI treatment, and shot peening on fatigue performance. The results were quite fascinating.

LTT Welds:

While LTT consumables have shown promising results in steels with lower yield strengths, the researchers found that they did not provide any significant improvement in fatigue life for the 1300 MPa steel. This was somewhat unexpected, as the anticipated reduction in tensile residual stresses did not materialize. Further investigation is needed to fully understand the underlying reasons for this.

HFMI-Treated Welds:

The HFMI-treated welds, on the other hand, did exhibit a considerable increase in fatigue strength. The combination of improved weld toe geometry and the introduction of compressive residual stresses proved to be an effective strategy for enhancing fatigue performance, even in these ultra-high-strength steels.

Shot-Peened Welds:

Perhaps the most impressive results came from the shot-peened samples. The intense surface treatment not only created a highly compressive residual stress state, but also seemed to delay the initiation of fatigue cracks. This led to a substantially higher fatigue life, especially at lower stress levels, with the fatigue strength curve exhibiting a much steeper slope.

Interestingly, while the HFMI-treated welds showed better fatigue performance than the as-welded samples, the shot-peened welds far surpassed even the HFMI-treated ones. This underscores the importance of carefully considering the nuances of weld bead geometry and residual stress management when designing for exceptional fatigue life.

The Art of Precision Welding

As a seasoned welder and fabricator, I can attest to the profound impact that attention to detail can have on the quality and longevity of a finished product. Whether it’s optimizing weld bead geometry, employing the right filler materials, or incorporating post-weld treatments, the choices we make in the welding process can make all the difference.

It’s a delicate balance, really – marrying the science of metallurgy with the art of skilled craftsmanship. But when you get it right, the results are nothing short of remarkable. I’ve seen welds that look almost seamless, where the fusion between the base material and the weld bead is so smooth and gradual that it’s almost impossible to tell where one ends and the other begins.

And the sense of pride that comes with creating a structure or component that can withstand the test of time – well, there’s simply nothing else like it. It’s a feeling of accomplishment that transcends the mere act of welding, tapping into a deeper sense of purpose and responsibility that we as fabricators have to our clients and the end users.

Embracing the Challenge

Of course, optimizing weld bead geometry is not without its challenges. Each material, each joint configuration, each set of operating conditions presents its own unique set of obstacles to overcome. It requires a keen eye, a steady hand, and a deep well of technical knowledge to navigate these complexities and arrive at the optimal solution.

But for those of us who have dedicated our careers to the art of welding and fabrication, these are the kinds of challenges we live for. We thrive on the opportunity to push the boundaries of what’s possible, to find innovative ways to improve the strength, durability, and performance of the structures we create.

And when we succeed – when we’re able to deliver a final product that exceeds all expectations, that stands the test of time, that becomes a testament to our skill and passion – well, that’s the kind of satisfaction that keeps us coming back, day after day, to the welding booth or the fabrication shop.

Conclusion

In the world of welding and metal fabrication, the pursuit of excellence is a never-ending journey. But with a deep understanding of the science behind weld bead geometry, and a relentless commitment to honing our craft, we can create structures that are not only visually stunning, but also engineered to withstand the rigors of daily use for decades to come.

As I reflect on my own experiences in this industry, I’m filled with a sense of pride and excitement for the future. The advancements in welding technology, the ongoing research into fatigue-resistant designs, and the unwavering dedication of professionals like myself – it all points to a bright future for the world of metal fabrication.

So if you’re a fellow welder or fabricator, I encourage you to embrace the challenge, to push the boundaries of what’s possible, and to never settle for anything less than perfection. After all, the structures we create are not just inanimate objects – they’re the foundations upon which entire industries are built. And that’s a responsibility we should all take immense pride in upholding.