As an experienced welder and metal fabricator, I’ve had the privilege of witnessing the remarkable advancements in robotic welding technology, particularly in the shipbuilding industry. Gone are the days when welding was solely the domain of skilled human hands. Today, the introduction of autonomous mobile robotics has transformed the way we approach these intricate and demanding tasks, ushering in a new era of unparalleled consistency, safety, and productivity.

Navigating the Challenges of Shipbuilding

The shipbuilding process is a marvel of engineering, with countless complex tasks that require meticulous attention to detail. From the intricate welding of steel frames to the seamless assembly of massive structures, every aspect of this industry demands the utmost precision. However, the dynamic and often unpredictable conditions of marine environments have long posed unique challenges for traditional welding methods.

Consider the ever-changing weather patterns, the relentless salt spray, and the constant vibrations that can wreak havoc on manual welding operations. Maintaining the necessary level of accuracy and consistency in such an unstructured environment has been a perpetual struggle, often leading to costly delays and compromised quality.

Embracing the Power of Robotic Welding

But just as the tide has turned, so too has the fortunes of the shipbuilding industry. The introduction of advanced robotic welding solutions has ushered in a new era of precision and efficiency, transforming the way we tackle these daunting tasks.

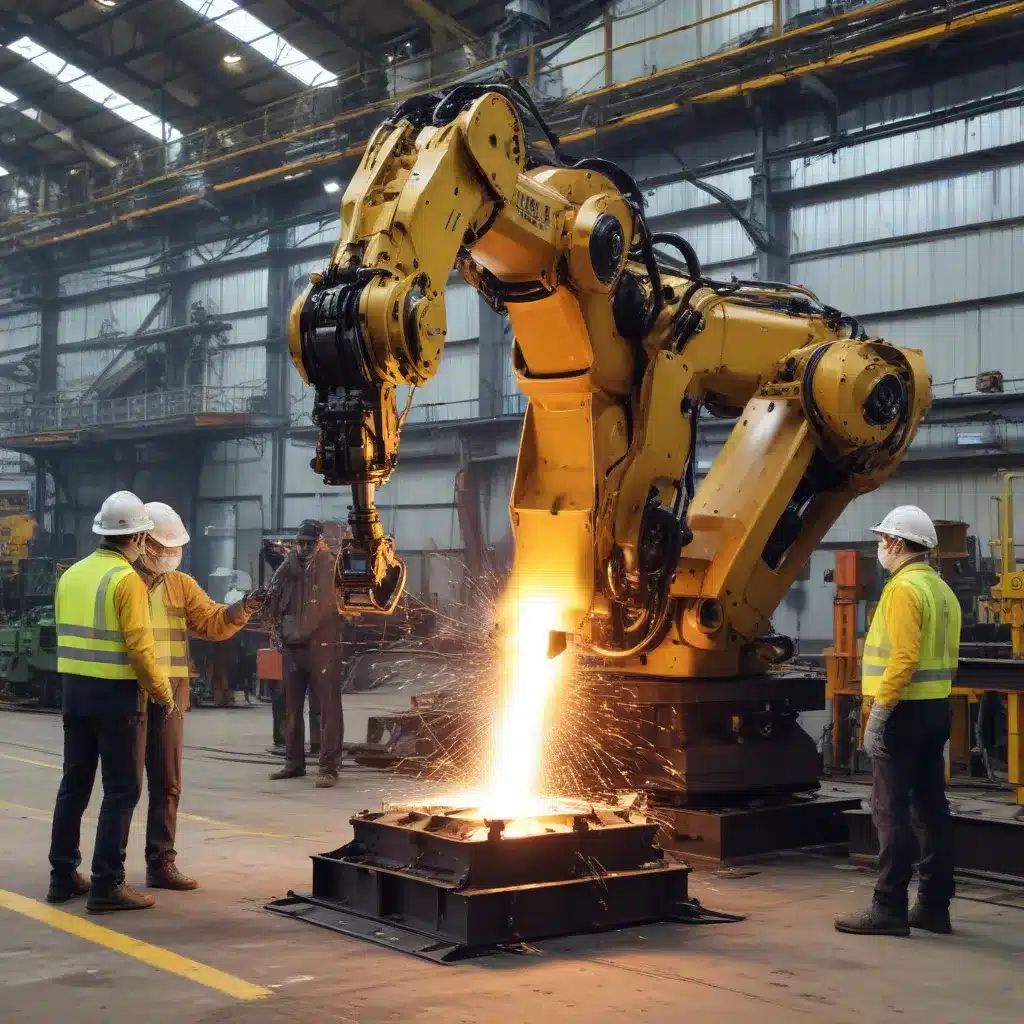

One such pioneering technology is the MR4Weld, a highly flexible and adaptable autonomous mobile robot developed by Comau, a global leader in industrial automation. Designed specifically to thrive in the harsh and dynamic conditions of marine environments, this remarkable system has proven to be a game-changer in the shipbuilding process.

Equipped with a suite of sophisticated sensors, advanced programming algorithms, and an intuitive navigation software, the MR4Weld effortlessly navigates through unstructured spaces, delivering unparalleled accuracy and repeatability in its welding operations. Managed by a single operator without the need for specialized robot programming expertise, this mobile robotic solution has revolutionized the way we approach welding in the shipbuilding industry.

Boosting Productivity and Quality

The integration of robotic welding systems like the MR4Weld has had a profound impact on the overall efficiency and quality of shipbuilding projects. By taking on the repetitive and physically demanding tasks, these automated systems free up skilled human workers to focus on more complex and value-added activities, creating a harmonious synergy between human expertise and robotic precision.

The results have been nothing short of remarkable. Shipyards that have embraced this transformative technology have reported significant reductions in production times and costs, all while maintaining the highest standards of weld quality and consistency. Gone are the days of painstaking manual adjustments and the risk of human error; with robotic welding, the precision and accuracy of each weld are virtually guaranteed.

Moreover, the MR4Weld’s ability to collect real-time data on welding parameters and joint quality has revolutionized the way we approach traceability and certification in the industry. By providing a comprehensive digital record of every weld, these robotic systems ensure that every component and structure meets the stringent safety and regulatory requirements that are the hallmark of the shipbuilding industry.

Embracing the Future of Welding

As a seasoned welder and fabricator, I’ve witnessed firsthand the profound impact that robotic welding solutions have had on the shipbuilding industry. These advanced systems have not only elevated the quality and consistency of our work but have also transformed the way we approach these critical tasks, ushering in a new era of unparalleled efficiency and safety.

Gone are the days of manual toil and the constant battle against the elements. With the MR4Weld and other cutting-edge robotic welding technologies, we now have the power to conquer the most challenging welding environments, delivering precision and reliability in even the most demanding of marine conditions.

But the benefits of robotic welding extend far beyond the shipbuilding industry. In fact, these innovative solutions are finding their way into a wide range of applications, from the construction of heavy infrastructure projects to the fabrication of large-scale suspension bridges and hoisting systems.

Embracing the Future of Fabrication

As I look to the future, I cannot help but feel a sense of excitement and anticipation for the continued evolution of robotic welding and its impact on the wider world of metal fabrication. The ability to harness the power of advanced automation, coupled with the unparalleled precision and consistency it offers, is truly a game-changer for our industry.

Just imagine the possibilities – the ability to tackle complex, large-scale projects with an unwavering commitment to quality, all while maximizing productivity and reducing the risks associated with manual welding. It’s a future that I, as a passionate welder and fabricator, am eager to be a part of.

And it’s not just about the technology itself; it’s about the way it empowers us, the skilled artisans of metal, to push the boundaries of what’s possible. With robotic welding systems like the MR4Weld at our disposal, we can focus on the true art of fabrication, unleashing our creativity and expertise to deliver truly exceptional and innovative solutions.

Conclusion

As I reflect on my journey as a welder and metal fabricator, I am filled with a sense of pride and excitement for the future. The advent of robotic welding has not only transformed the way we approach our craft but has also elevated the entire industry, ushering in a new era of precision, efficiency, and safety.

Through the integration of advanced autonomous mobile robotics, we now have the power to conquer even the most challenging welding environments, delivering unparalleled consistency and quality in our work. And as we continue to embrace these transformative technologies, I have no doubt that the future of metal fabrication will be nothing short of remarkable.

So, let us all embrace the exciting possibilities that lie ahead and continue to push the boundaries of what’s possible in our ever-evolving industry. After all, as welders and fabricators, we are the architects of the physical world, and with the power of robotic welding at our fingertips, the possibilities are truly endless.