As an experienced welder and metal fabricator, I’ve had the privilege of working with a wide range of materials and techniques over the years. Today, I want to share my insights on the fascinating world of pouch cell fabrication, particularly the use of laser and ultrasonic welding methods.

Joining Thin Foils: The Challenges and Innovations

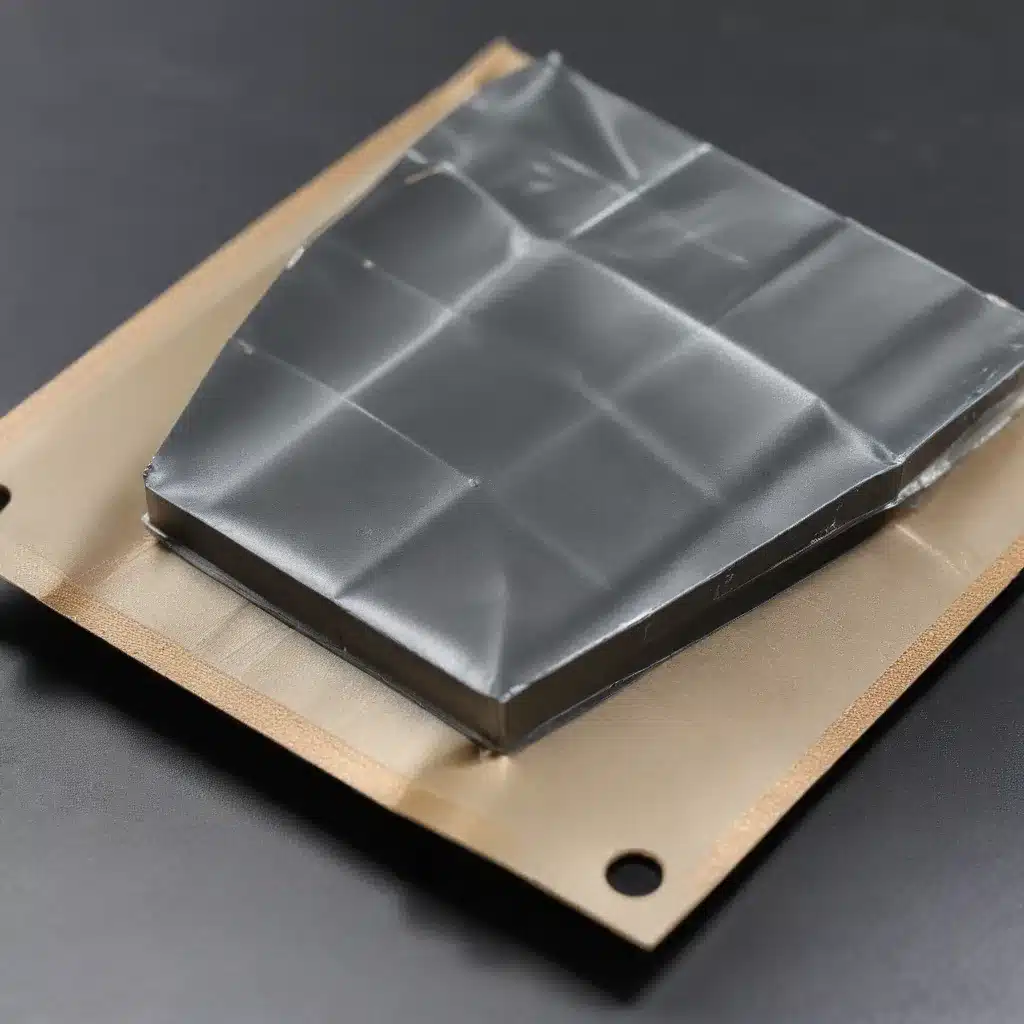

In my line of work, I’ve seen the increasing demand for efficient and flexible joining methods, especially when it comes to working with thin foils or micro-foils. These delicate materials are finding their way into a variety of industries, from microelectronics to aerospace and automotive applications. One of the most critical areas where these thin foils are used is in the manufacturing of lithium-ion battery pouch cells for electric vehicles (EVs).

The Importance of Reliable Connections

Within these pouch cells, multiple thin foils, representing the current collectors, need to be electrically connected to enable the flow of current during charge and discharge cycles. Ensuring reliable, low-resistance connections is crucial for efficient energy transfer and overall battery performance. As the demand for pouch cell batteries continues to rise, achieving manufacturing scalability becomes a significant challenge.

Overcoming the Limitations of Traditional Welding

Traditionally, the go-to welding method for joining current collectors to tabs has been ultrasonic welding (USW). This solid-state, contact-based process utilizes high-frequency mechanical vibrations to generate local heat and deformation, resulting in a metallurgical bond. While USW offers advantages like lower energy consumption and minimal filler metal requirements, it also has its limitations. As a contact-based method, USW has restricted flexibility in terms of joint placement, higher cycle times, and the potential for part deformation during the joining process.

Exploring Laser Welding as an Alternative

To address these limitations, laser welding (LW) has emerged as a promising alternative. As a non-contact process, LW uses a focused laser beam to melt and fuse the materials. This approach provides significant advantages, such as increased flexibility in joint placement, the ability to handle complex geometries, reduced cycle times, and the potential for tab size reduction.

Comparing the Advantages of Laser and Ultrasonic Welding

When it comes to welding current collectors to tabs, both LW and USW have their strengths and weaknesses. USW excels at producing a strong metallurgical bond and avoiding the formation of brittle intermetallic compounds (IMCs) or phases. However, it can result in foil distortion, and the lack of complete fusion in the joint can limit the weld’s shear strength.

On the other hand, LW offers the flexibility to place joints in complex geometries and faster welding speeds. But it does present challenges when welding dissimilar materials, as the potential for metallurgical incompatibilities can lead to weld defects and IMC formation.

Investigating the Performance of Laser and Ultrasonic Welded Joints

To better understand the suitability of LW as an alternative to USW for pouch cell manufacturing, I’ve conducted a comprehensive study comparing the two welding techniques. Let’s dive into the key findings.

Mechanical and Microstructural Analysis

Through a series of lap shear tests, I’ve observed some intriguing trends. For similar material combinations, such as Al foils-to-Al tabs and Cu foils-to-CuNi tabs, USW generally provided better mechanical interlocking near the valleys of the sonotrode pattern. However, the joints sometimes lacked proper bonding near the sonotrode peaks, which limited the overall weld strength.

In contrast, the LW process achieved better penetration and weld strength, despite the presence of some pore formation in the fusion zone. This can be attributed to the high-intensity, localized heat input and rapid heating-cooling cycles inherent to the LW process.

When it comes to dissimilar material combinations, like Al foils-to-CuNi tabs and Cu foils-to-Al tabs, the story becomes more complex. USW demonstrated a delicate balance between the applied energy and the resulting interface characteristics. Excessive plastic deformation and weld zone thinning were observed, particularly on the aluminum side.

LW, on the other hand, tended to form brittle IMCs, such as Al2Cu and Al4Cu9, which can weaken the joints and induce premature cracking in the fusion zone. This highlights the importance of carefully controlling the welding parameters to mitigate the formation of detrimental IMCs.

Electrical and Thermal Performance

Alongside the mechanical and microstructural analysis, I also evaluated the electrical contact resistance and temperature rise at the welded joints. Interestingly, the LW joints exhibited approximately 13% higher contact resistance and a 6% higher temperature rise compared to the USW joints when subjected to 50 A and 75 A passing currents.

This can be attributed to the lower weld fusion area in the LW process, which directly impacts the electron flow and heat dissipation at the joint. Maintaining low electrical resistance and temperature regulation are crucial factors in ensuring efficient and reliable battery performance during charge-discharge cycles.

Balancing the Tradeoffs: Choosing the Right Welding Technique

As an experienced welder, I’ve learned that there’s no one-size-fits-all solution when it comes to welding techniques. Both LW and USW have their unique strengths and limitations, and the choice ultimately depends on the specific requirements of the application.

For applications where joint strength and mechanical interlocking are the primary concerns, USW may be the preferred choice, particularly for similar material combinations. The solid-state nature of USW and its ability to avoid the formation of detrimental IMCs make it a robust option.

However, when flexibility in joint placement, faster welding speeds, and single-sided access are crucial, LW can be a compelling alternative. While LW may face challenges with dissimilar material welding and IMC formation, careful parameter optimization can help mitigate these issues.

Ultimately, the selection of the welding technique should be based on a comprehensive assessment of the specific requirements, such as joint strength, electrical performance, and manufacturing constraints. By understanding the nuances of each welding method, we can make informed decisions to deliver high-quality, reliable pouch cell fabrication solutions.

Embracing the Future of Battery Manufacturing

As the demand for electric vehicles and energy storage solutions continues to grow, the need for efficient and scalable pouch cell manufacturing processes becomes increasingly critical. By leveraging the strengths of both laser and ultrasonic welding, we can push the boundaries of what’s possible in the world of battery fabrication.

I’m excited to see how the industry will continue to evolve, with new innovations and advancements in welding technologies. As an experienced welder and fabricator, I’m proud to be a part of this dynamic landscape, contributing my expertise to help shape the future of sustainable energy solutions.

If you’re interested in exploring the possibilities of laser and ultrasonic welding for your pouch cell fabrication needs, I encourage you to visit The Weld Fab website. Our team of skilled professionals is dedicated to providing cutting-edge welding and fabrication solutions tailored to your specific requirements.