As an experienced welder and metal fabricator, I’ve always been fascinated by the art of precision welding. In my line of work, achieving seamless, high-quality welds is not just a technical requirement – it’s a point of pride. Whether I’m working on intricate jewelry pieces or large-scale industrial components, the pursuit of flawless, integrated joints is a constant driving force.

The Beauty of Seamless Welds

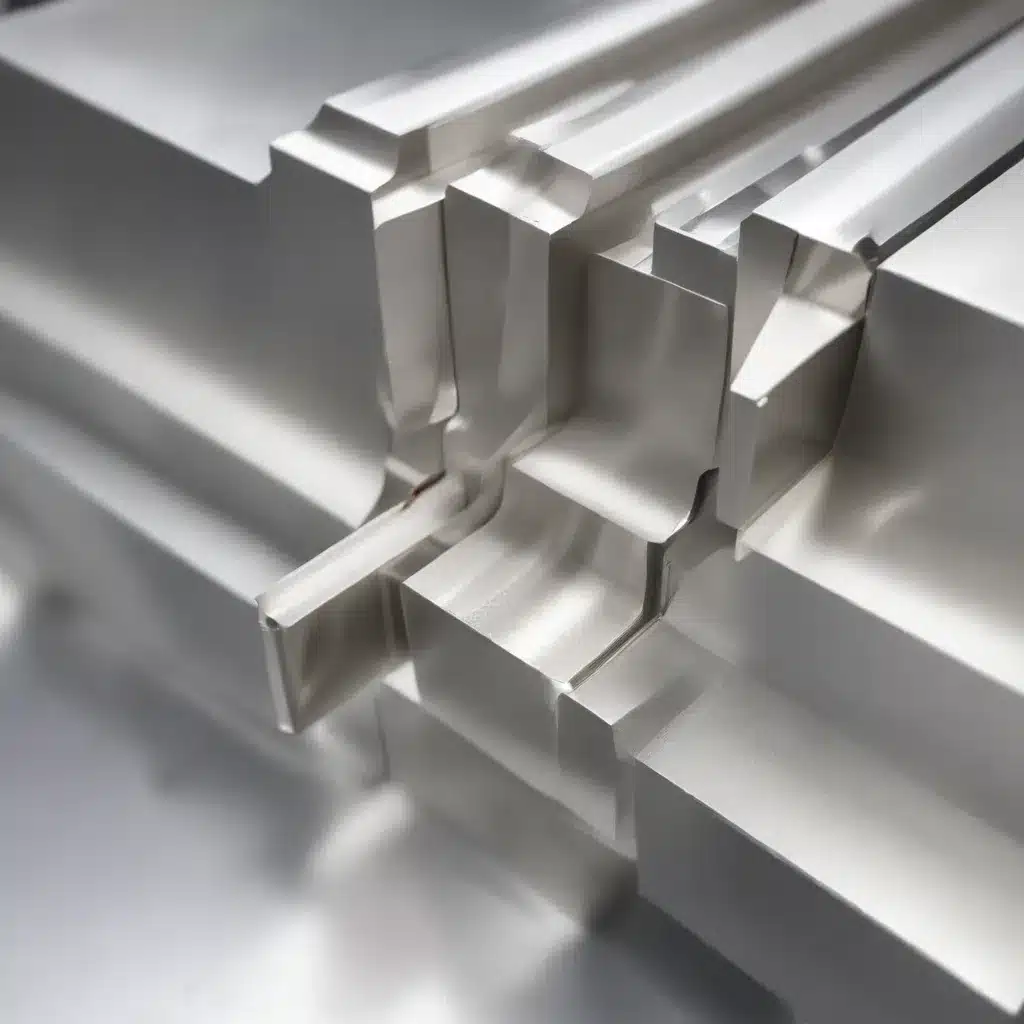

Seamless welds are the holy grail of metalworking, where two pieces of metal are joined together in a way that the weld is virtually indistinguishable from the surrounding material. It’s not just about the aesthetic appeal, though that is certainly a significant factor. Seamless welds also play a crucial role in ensuring the structural integrity and longevity of the fabricated components.

When a weld is perfectly executed, it becomes an integral part of the overall design, blending in seamlessly and enhancing the visual appeal of the finished product. Imagine running your fingers over a weld and feeling no discernible irregularities – that’s the kind of craftsmanship that truly sets the masters apart.

Precision Laser Welding: The Key to Seamless Joints

In my experience, one of the most powerful tools for achieving seamless welds is precision laser welding. This non-contact welding technique utilizes a highly concentrated laser beam to melt and fuse the materials, creating a narrow, deep weld with minimal heat-affected zones.

The precision and control offered by laser welding are unparalleled. Unlike traditional welding methods, the laser beam can be precisely positioned and precisely controlled, allowing me to achieve welds of exceptional quality and consistency. The result? Joints that blend effortlessly with the parent material, ensuring a uniform appearance and superior structural integrity.

Mastering the Intricacies of Laser Welding

Perfecting the art of laser welding is no easy feat, and it’s a journey I’ve been on for many years. It’s a process that demands meticulous attention to detail, a deep understanding of material properties, and a keen eye for the nuances of the welding process.

One of the critical factors in achieving seamless welds with laser welding is the ability to precisely control the heat input. Too much heat can lead to distortion and degradation of the base material, while too little heat may result in incomplete fusion and weak joints. It’s a delicate balance that requires a steady hand and a wealth of experience.

To ensure consistent weld quality, I also place a strong emphasis on proper equipment maintenance and calibration. Regularly inspecting and servicing the laser welding system is essential for maintaining the tight tolerances and precise parameters required for seamless welds.

The Importance of Preparation and Filler Selection

Achieving a seamless weld, however, doesn’t begin and end with the welding process itself. Proper preparation of the joint surfaces is crucial, as any contaminants or irregularities can compromise the weld quality.

Before I even fire up the laser, I meticulously clean the surfaces, removing any traces of rust, oil, or paint. This ensures a clean, uninterrupted fusion between the base material and the weld. Additionally, I carefully bevel and align the joint edges to facilitate smooth weld penetration and uniform fusion.

The selection of the right filler material is another critical consideration. The filler must be compatible with the base metal, matching its chemical composition and mechanical properties. This compatibility helps to minimize the risk of weld defects, such as cracking or porosity, and ensures a seamless integration of the weld into the parent material.

The Art of Controlling Travel Speed

One often-overlooked aspect of achieving seamless welds is the careful control of travel speed during the welding process. The travel speed directly influences the heat input and the geometry of the weld pool, which in turn affects the overall appearance and integrity of the weld.

I’ve found that maintaining a consistent, optimal travel speed is crucial for producing a uniform weld bead and minimizing any discontinuities or irregularities. Too fast, and the weld may be incomplete; too slow, and the excessive heat input can lead to distortion and discoloration.

Through years of practice and experimentation, I’ve developed a keen sense of rhythm and timing when it comes to controlling the travel speed. It’s a delicate dance, where I’m constantly adjusting and fine-tuning to ensure the weld’s seamless integration with the surrounding metal.

The Final Touches: Grinding and Polishing

Even after the welding process is complete, the pursuit of seamless perfection doesn’t end. In many of my projects, the final steps of grinding and polishing are essential for achieving that elusive, flawless finish.

Using specialized tools and techniques, I carefully grind down any surface irregularities, blending the weld bead into the parent material. This meticulous process not only enhances the visual appeal but also improves the corrosion resistance and overall durability of the welded joint.

The final step, polishing, takes the seamless aesthetic to the next level. By meticulously buffing and shining the surface, I can create a virtually indistinguishable transition between the weld and the surrounding metal. It’s a time-consuming process, but the end result is nothing short of breathtaking.

The Satisfaction of a Job Well Done

As a welder and fabricator, there’s nothing quite like the sense of pride and accomplishment that comes with producing a seamless weld. It’s a testament to my skills, my attention to detail, and my unwavering commitment to quality.

When I step back and admire a finished project, where the welds are completely integrated and indistinguishable from the base material, I can’t help but feel a deep sense of satisfaction. It’s not just about the technical achievement – it’s about the journey of perfecting my craft, the countless hours of practice, and the relentless pursuit of excellence.

Sharing the Passion for Precision

I take great joy in sharing my passion for precision welding with others in the industry. Whether I’m mentoring a young apprentice or collaborating with a fellow fabricator, I love to impart the knowledge and techniques that have helped me achieve such seamless results.

It’s my hope that by sharing my experiences and insights, I can inspire others to strive for the same level of craftsmanship and attention to detail. After all, the world of metal fabrication is one that is constantly evolving, and the pursuit of seamless perfection is a never-ending challenge that keeps us all on our toes.

So, if you’re a fellow welder or fabricator, I encourage you to embrace the pursuit of seamless welds. It’s a journey that will test your skills, push your boundaries, and ultimately, fill you with a sense of pride and accomplishment that is truly unmatched.

And for those of you outside the industry, I invite you to explore the fascinating world of precision welding and metal fabrication. The level of craftsmanship and attention to detail involved is truly awe-inspiring, and I’d be more than happy to share my experiences and insights with you. Who knows, perhaps you’ll even be inspired to pick up a welding torch and join me in this exhilarating journey.

Conclusion: The Enduring Beauty of Seamless Welds

In the ever-evolving world of metal fabrication, the pursuit of seamless welds remains a constant and compelling challenge. It’s a pursuit that demands technical mastery, an eye for detail, and a deep passion for the craft. As an experienced welder, I can attest to the immense satisfaction that comes with producing a flawless, integrated joint – a testament to the skill and dedication of the metalworker.

Whether you’re a seasoned professional or a newcomer to the industry, the beauty and importance of seamless welds cannot be overstated. They not only enhance the aesthetic appeal of the finished product but also play a crucial role in ensuring structural integrity and longevity. By embracing the principles of precision laser welding and honing our craft, we can continue to push the boundaries of what’s possible in the world of metal fabrication.

So, let us raise a metaphorical torch to the art of seamless welding, and let our passion for this pursuit shine brightly, inspiring others to join us in our quest for perfection. After all, in this endlessly fascinating field, the pursuit of seamless welds is not just a technical challenge – it’s a lifelong journey of self-discovery, creativity, and the relentless pursuit of excellence.