As an experienced welder and metal fabricator, I’ve seen firsthand the remarkable advancements in welding technologies that have transformed our industry. One technique that has particularly captured my attention is laser welding, a precision-driven process that offers unparalleled speed and control in the quest for achieving seamless joints.

In today’s fast-paced manufacturing landscape, the demand for exotic materials and intricate components is soaring. Industries like aerospace, automotive, and even medical device production are pushing the boundaries of innovation, seeking out materials that deliver exceptional strength, corrosion resistance, and temperature tolerance. And as someone who’s spent countless hours hunched over a welding torch, I can attest to the unique challenges that come with working with these specialized alloys.

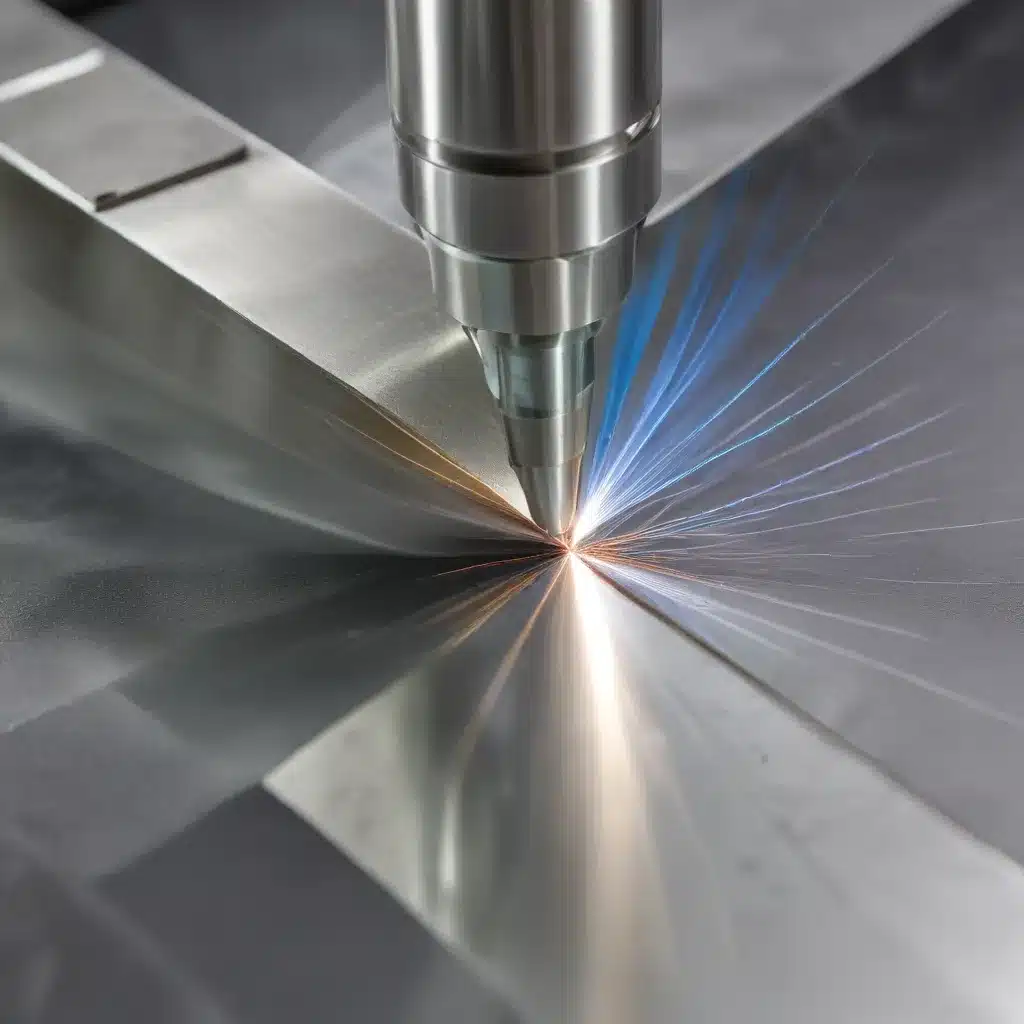

That’s where laser welding shines. With its highly concentrated beam of light energy, this cutting-edge technique allows us to melt and join metals with unprecedented precision, speed, and control. Gone are the days of struggling with the nuances of traditional welding processes like TIG or MIG when faced with exotic materials. Laser welding has emerged as a true game-changer, unlocking new possibilities for achieving seamless, high-quality welds that are essential for the success of today’s most demanding manufacturing projects.

The Precision Advantage of Laser Welding

As a seasoned metal fabricator, I’ve always prided myself on my ability to produce welds that are not only structurally sound but visually stunning. After all, a seamless weld isn’t just a matter of aesthetics – it’s a testament to the skill and attention to detail that goes into the fabrication process. And when it comes to achieving that level of precision, laser welding is simply unparalleled.

The key lies in the laser’s unique properties. Unlike traditional welding methods that rely on an arc or a flame, laser welding utilizes a highly concentrated beam of light energy to melt and fuse the metal. This concentrated energy allows for pinpoint precision, enabling us to weld intricate components and complex geometries with remarkable accuracy. Gone are the days of struggling with heat distortion or unsightly weld beads – with laser welding, we can create welds that blend seamlessly with the parent material, ensuring a uniform appearance that meets the most exacting standards.

But the benefits of laser welding extend beyond just visual appeal. The precision of this technique also translates to superior mechanical properties, with welds that exhibit exceptional strength and integrity. By precisely controlling the heat input and minimizing the heat-affected zone, we can produce welds that are remarkably free of defects like porosity or cracking, ensuring the long-term reliability and performance of the fabricated components.

Unlocking the Potential of Exotic Materials

As I mentioned earlier, the demand for exotic materials in manufacturing is on the rise, and with good reason. These specialized alloys offer unparalleled properties that are essential for pushing the boundaries of innovation. From the aerospace industry’s need for lightweight, high-strength components to the medical field’s quest for durable, corrosion-resistant implants, the applications for exotic materials are endless.

But with these advanced materials come unique challenges, and that’s where laser welding truly shines. Traditional welding methods can struggle with the specific properties of exotic alloys, leading to issues like poor weld penetration, excessive heat input, or metallurgical incompatibility. Laser welding, on the other hand, provides the precision and control needed to overcome these obstacles, allowing us to seamlessly join even the most demanding materials.

Take titanium, for example. This lightweight, ultra-strong metal is a staple in the aerospace and medical industries, but its high thermal conductivity and low melting point can make it tricky to weld using conventional techniques. With laser welding, however, we can precisely control the heat input, ensuring a clean, uniform weld that maintains the integrity of the base material. The same holds true for other exotic alloys like Inconel and tantalum, which are prized for their exceptional corrosion resistance and temperature tolerance – laser welding allows us to harness their full potential without compromising quality or performance.

Achieving Seamless Welds at High Speeds

One of the most impressive aspects of laser welding is its ability to deliver consistently high-quality welds at astonishing speeds. In an industry where time is of the essence, this capability is truly game-changing, allowing us to improve production efficiency and meet even the tightest of deadlines.

The secret lies in the laser’s unique properties. Unlike traditional welding methods that rely on a relatively broad heat source, the laser’s concentrated beam of energy can quickly melt and fuse the metal, creating welds at a fraction of the time it would take using other techniques. This speed advantage is particularly crucial when working with exotic materials, where the risk of defects or distortion increases with each passing second.

But it’s not just about speed – laser welding also enables us to maintain exceptional control and precision, even at lightning-fast welding speeds. By carefully calibrating the laser’s power, focal point, and travel speed, we can ensure that the weld seamlessly integrates with the parent material, creating a uniform, high-quality finish that meets the most stringent quality standards.

The Art of Crafting Seamless Welds

As a seasoned metal fabricator, I’ve always taken great pride in the craftsmanship of my work. To me, a seamless weld isn’t just a functional connection – it’s a work of art, a testament to the skill and attention to detail that goes into the fabrication process. And with laser welding, I’ve been able to take my welding artistry to new heights.

It’s not just about the speed and precision of the laser – it’s also about the meticulous preparation and attention to detail that goes into every single weld. From thoroughly cleaning the surfaces to carefully selecting the appropriate filler material, every step in the process is critical to ensuring a flawless, seamless result. And when I step back and admire the finished product, the sense of accomplishment I feel is truly unparalleled.

But it’s not just about the final result – it’s also about the journey. As I work with the laser, I can’t help but marvel at the sheer power and control it provides. The way the concentrated beam of light effortlessly slices through the metal, creating a perfectly uniform weld bead, is nothing short of mesmerizing. And with each project, I find myself growing more and more in awe of the capabilities of this remarkable technology.

The Future of Seamless Fabrication

As I look towards the future of our industry, I can’t help but feel excited about the endless possibilities that laser welding holds. With its unparalleled speed, precision, and control, I believe this technology will continue to push the boundaries of what’s possible in metal fabrication, enabling us to tackle even the most complex and demanding projects with confidence.

Just imagine the impact that seamless laser-welded joints could have on the aerospace industry, where every ounce of weight and every millimeter of space is critical. Or the transformative effect it could have on the medical device sector, where the need for durable, corrosion-resistant implants is paramount. The potential is truly limitless, and as a metal fabricator, I can’t wait to see how this technology will continue to shape the future of our industry.

Of course, the journey won’t be without its challenges. As with any advanced technology, laser welding requires a deep understanding of the process, as well as a commitment to ongoing training and education. But for those of us who are passionate about our craft, I believe the rewards will far outweigh the investment.

After all, at the end of the day, what could be more satisfying than creating a weld that seamlessly blends with the parent material, a testament to our skill and precision as metal fabricators? It’s a level of craftsmanship that I’m proud to strive for, and with the power of laser welding at our fingertips, I believe the possibilities are truly endless.

So if you’re a fellow metal fabricator or welder, I encourage you to embrace the power of laser welding and let it transform your approach to creating seamless, high-quality joints. Together, let’s push the boundaries of what’s possible in our industry and continue to redefine the art of precision fabrication. The future is ours to shape, one seamless weld at a time.