As an experienced welder and metal fabricator, I’ve seen the evolution of welding technology firsthand, and I can confidently say that laser welding has revolutionized the way we approach stainless steel fabrication. This innovative technique has not only transformed the industry but has also allowed us to push the boundaries of what’s possible when it comes to strength, precision, and efficiency.

The Science Behind Laser Welding Stainless Steel

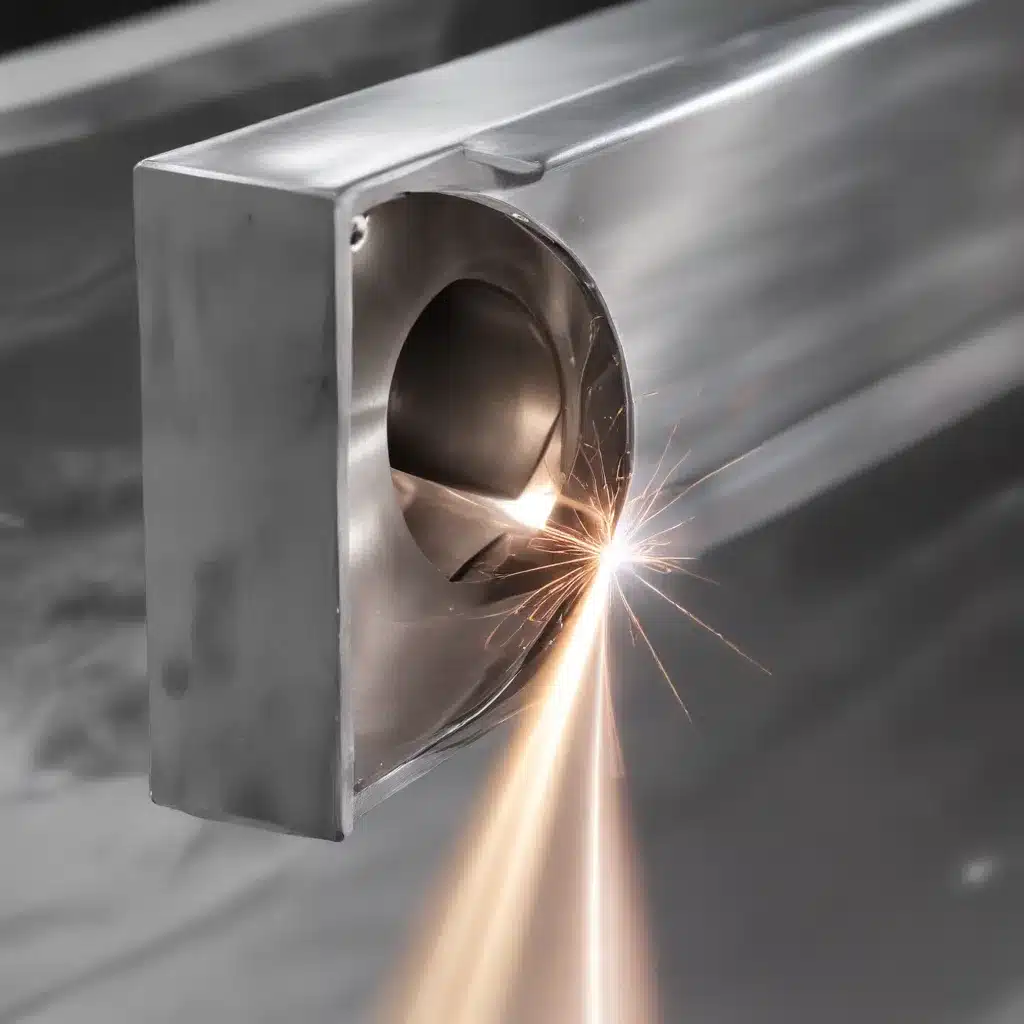

At the heart of laser welding is the power of a highly focused beam of light. This concentrated beam of energy delivers an intense amount of heat, precisely melting the stainless steel components and fusing them together seamlessly. Unlike traditional welding methods, such as MIG or TIG, laser welding provides exceptional control over the heat input, resulting in a localized and targeted heat source.

The key advantage of this precision is the minimization of distortion and warping in the surrounding areas. This means that post-welding treatments like straightening or stress relieving are often unnecessary, saving time and resources. The rapid solidification process during laser welding can also lead to the formation of a narrow heat-affected zone (HAZ), which experiences minimal microstructural changes compared to other welding methods. This preserves the desirable material properties of stainless steel, such as corrosion resistance and mechanical strength.

Understanding the metallurgical aspects of laser welding is crucial for optimizing the welding quality and performance. Factors like alloy composition, thermal conductivity, and even heat treatment processes play a vital role in achieving the desired results when working with different types of stainless steel. For instance, austenitic stainless steels like 316L exhibit excellent weldability due to their low carbon content and high nickel content, which the laser welding process helps maintain, ensuring optimal corrosion resistance and mechanical properties.

Advantages of Laser Welding Stainless Steel

One of the key advantages of laser welding stainless steel is its ability to provide exceptional weld quality while minimizing distortion. The concentrated heat source generated by the laser beam allows for precise control over the heat input, ensuring that the welded components maintain their structural integrity and dimensional accuracy. This is a significant improvement over traditional welding methods, which often result in substantial distortion and warping.

Another notable advantage is the increased welding speed offered by laser welding technology. The focused laser beam delivers a high energy density, enabling rapid melting and solidification of the stainless steel material. This translates into reduced production time and improved efficiency, allowing for higher productivity in your fabrication operations.

Laser welding also reduces the risk of cracking in the stainless steel material, thanks to its ability to penetrate deeper into the medium compared to other welding methods. This is particularly beneficial when working with 316L stainless steel, which is known for its high resistance to cracking.

Furthermore, laser-welded joints exhibit superior corrosion resistance due to the reduced heat input during the fusion process. Traditional welding methods often introduce excessive heat, which can alter the chemical composition of stainless steel and compromise its corrosion-resistant properties. In contrast, laser welding minimizes the heat-affected zones, preserving the material’s original characteristics and ensuring long-term durability.

One additional advantage of laser welding is its non-contact nature, eliminating physical contact between the tooling and the metal surface. Traditional welding processes involve direct contact between electrodes or filler materials and the metal being joined, which can lead to contamination or damage to sensitive components. Laser welding eliminates this concern by utilizing a focused laser beam that melts and fuses the metals without any physical interaction.

Selecting the Right Laser System

When it comes to laser welding stainless steel, the choice of the right laser system can have a significant impact on the quality and efficiency of the welding process. Let’s explore some key factors to consider:

Laser Power: Laser power plays a crucial role in determining the effectiveness of stainless steel welding, especially when dealing with materials like 316L stainless steel and duplex stainless steel. Higher laser power offers deeper penetration capabilities, allowing for the efficient joining of thick sections. However, it’s important to note that thin materials may require additional precautions due to the increased energy density. Therefore, when considering laser power output, you must carefully assess the base material thickness and select an appropriate laser power level for medium-depth welds.

Beam Quality: The beam quality of a laser is another critical consideration when choosing a system for stainless steel welding. A well-focused beam with a good spatial intensity distribution enhances welding precision and reduces defects such as porosity or undercutting. This ensures high-quality welds with excellent joint strength and aesthetics. Therefore, it’s essential to opt for a laser system that provides high beam quality.

Pulse Duration: Pulse duration refers to the length of time during which energy is delivered by the laser source, and it has a significant impact on the welding process’s outcome, depending on the thickness of the stainless steel being welded. Shorter pulses are suitable for thin materials as they minimize heat input and reduce potential distortion or burn-through issues. On the other hand, longer pulses are effective for thicker sections, as they allow better control over heat dissipation and fusion depth.

Optimizing Welding Parameters

Finding the right settings is crucial for achieving high-quality welds when laser welding stainless steel. One of the first steps in the welding process is conducting initial trials to determine the optimal laser parameters for the specific stainless steel grades and joint configurations you are working with. Each grade of stainless steel may require different settings due to variations in composition and metallurgical properties.

Adjusting the focus position can help control weld width and depth, ensuring proper fusion without excessive heat input. The focal position plays a significant role in laser welding stainless steel. By adjusting it, you can control the weld geometry, width, and depth of the weld. A focused beam allows for precise energy concentration at a specific point, resulting in deep penetration. However, if the focus is too narrow or shallow, there may be insufficient fusion between the base materials. On the other hand, if the focus is too wide or deep, excessive heat input can lead to distortions and defects in the welded joint. Fine-tuning the focal position enables you to strike a balance between penetration depth and thermal distortion.

In addition to adjusting the focal position, fine-tuning the pulse frequency and power levels is crucial for achieving optimal results when laser welding stainless steel. The pulse frequency determines how often energy is delivered during the laser beam welding process. Higher frequencies provide rapid heating cycles that result in shallow welds, suitable for thin materials or surface treatments. Conversely, lower frequencies allow for deeper penetration into thicker welding materials but increase heat input. Balancing the pulse frequency and power levels ensures that the desired penetration depth is achieved without causing excessive thermal distortion.

To enhance the welding environment during the laser welding of stainless steel, it’s common practice to use shielding gases such as argon, carbon dioxide, or helium. These gases provide effective shielding, protecting the weld pool from atmospheric contamination, which could lead to defects in the final weld. Argon is commonly used for non-reactive metals like stainless steel and mild steel due to its inert properties, while helium offers high thermal conductivity, making it suitable for high-power laser applications. The choice of shielding gas depends on factors such as material thickness, laser power, and desired weld quality.

Embracing the Future of Fabrication

As I reflect on my experiences as a welder and metal fabricator, I’m truly amazed by the advancements in laser welding technology and how it has transformed the industry. The precision, speed, and efficiency offered by these cutting-edge machines have revolutionized the way we approach stainless steel fabrication, enabling us to push the boundaries of what’s possible.

One of the most exciting aspects of laser welding is its compatibility with a wide range of materials, including not only stainless steel but also advanced alloys like titanium and nickel-based materials. This versatility opens up new avenues for innovation, allowing us to explore complex designs and material combinations that were once deemed impractical or even impossible using traditional welding methods.

As we continue to embrace the power of laser welding, I’m confident that the future of fabrication will be even more remarkable. The seamless integration of these machines with automated systems and robotic technologies has elevated the level of precision, consistency, and productivity in our operations. We can now tackle larger-scale projects with greater efficiency, delivering high-quality results that meet the most demanding industry standards.

The applications of laser welding extend far beyond the traditional realms of manufacturing, with emerging technologies like additive manufacturing and 3D printing relying on this revolutionary technique for intricate and complex part fabrication. This opens up new frontiers in design, allowing us to explore innovative solutions that were once unimaginable.

Looking ahead, I’m excited to see how the continued advancements in laser welding technology will shape the future of our industry. As welders and fabricators, we have the opportunity to be at the forefront of this transformation, harnessing the power of precision and efficiency to create exceptional, high-strength connections that will redefine the boundaries of what’s possible.

If you’re interested in exploring the world of laser welding and discovering how it can transform your fabrication operations, I encourage you to visit theweldfab.com. Our team of experts is dedicated to providing you with the latest innovations, industry insights, and customized solutions to help you stay ahead of the curve and excel in the ever-evolving landscape of metal fabrication.