The Art of Fabrication: Welding for Life in the Final Frontier

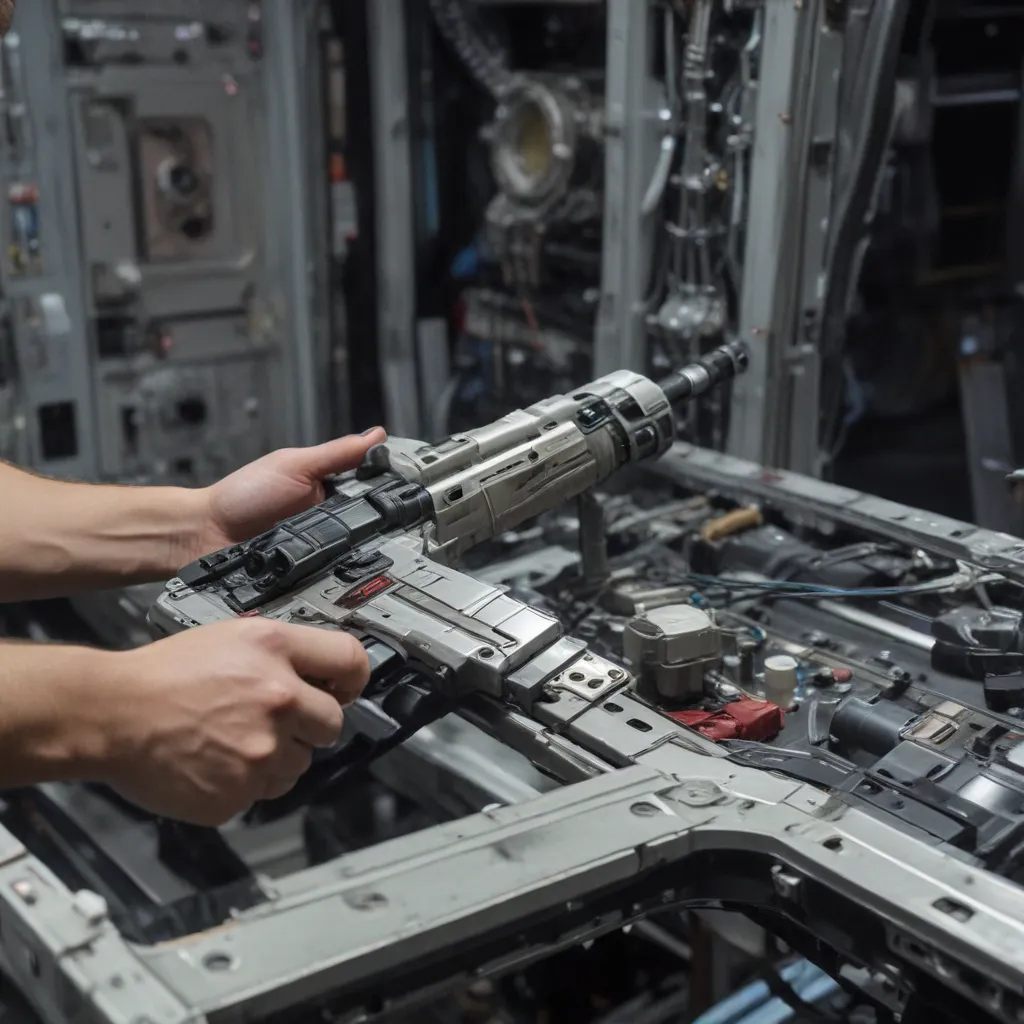

As an experienced welder and metal fabricator, I’ve had the privilege of working on a wide range of projects, from intricate automotive parts to large-scale industrial equipment. But one of the most fascinating and challenging endeavors I’ve been a part of is fabricating survival tools and weapons for the crew of Space Station 14.

You see, the world of space exploration is a harsh and unforgiving one, where even the simplest tasks can become a matter of life and death. And when it comes to ensuring the safety and well-being of the brave souls who venture out into the vastness of the cosmos, we fabricators play a vital role.

Imagine being trapped on a space station, cut off from the rest of the world, with only the tools and resources at your disposal. That’s the reality faced by the crew of Space Station 14, and it’s where my expertise as a welder and fabricator comes into play.

Precision and Durability: The Hallmarks of Survival Fabrication

When it comes to fabricating survival tools and weapons for Space Station 14, precision and durability are paramount. These aren’t just ordinary tools – they’re the difference between life and death for the crew, and every single detail matters.

Take, for example, the process of welding together a makeshift survival knife. This seemingly simple task requires a level of skill and attention to detail that would make even the most seasoned metalworker sweat. The blade must be forged with the perfect balance of strength and flexibility, able to withstand the rigors of extreme conditions and still maintain its sharp edge.

And it’s not just the blade that requires our utmost care – the handle, too, must be crafted with the utmost precision. It needs to provide a secure and comfortable grip, even when the user’s hands are slick with sweat or encased in bulky spacesuit gloves. A poorly designed handle could mean the difference between a successful mission and a tragic outcome.

But it’s not just the knives that we fabricate – oh no, there’s so much more. From sturdy survival hammers and wrenches to reinforced toolboxes and makeshift repair kits, every single item we produce is a testament to the power of skilled metalworking.

Adapting to the Harsh Realities of Space

Of course, fabricating for Space Station 14 isn’t just about creating durable and functional tools – it’s also about adapting to the unique challenges and constraints of the space environment.

Take, for example, the issue of material availability. Unlike on Earth, where we have access to a seemingly endless array of raw materials, the crew of Space Station 14 are limited to the resources they can scavenge or harvest from their own surroundings. This means that we as fabricators need to be incredibly resourceful, constantly searching for new and innovative ways to repurpose and recycle the materials at our disposal.

And then there’s the matter of gravity, or rather, the lack thereof. Working in the weightless environment of space requires a whole new set of techniques and considerations. Welding, for instance, becomes an entirely different beast, with the molten metal behaving in ways that would be unthinkable on Earth.

But we fabricators are nothing if not adaptable, and we’ve risen to the challenge time and time again. Through trial and error, we’ve developed specialized techniques and tools that allow us to work seamlessly in the zero-gravity environment of Space Station 14, ensuring that the crew always has the survival equipment they need to thrive.

The Rewards of Fabrication: Saving Lives and Preserving Hope

As a welder and fabricator, I take immense pride in the work we do for the crew of Space Station 14. Every time we forge a new survival tool or weapon, we’re not just creating an object – we’re quite literally saving lives.

It’s a heavy responsibility, to be sure, but one that we embrace with unwavering dedication. Because when the chips are down, and the crew is facing seemingly insurmountable odds, it’s our fabricated tools and weapons that can mean the difference between survival and tragedy.

And the satisfaction that comes from knowing that our work has played a crucial role in preserving hope and keeping the crew of Space Station 14 alive? Well, it’s a feeling that’s simply beyond words.

Pushing the Boundaries: Innovation in Survival Fabrication

But the work we do as fabricators for Space Station 14 isn’t just about meeting the current needs of the crew – it’s also about pushing the boundaries of what’s possible.

As the station’s environment becomes increasingly hostile and unpredictable, we’re constantly exploring new and innovative ways to fabricate tools and weapons that can withstand the harshest of conditions. From experimenting with cutting-edge alloys to developing revolutionary welding techniques, we’re always striving to stay one step ahead of the game.

And it’s not just about making things more durable – we’re also focused on increasing the versatility and functionality of our fabricated items. A simple survival knife, for instance, might be outfitted with a built-in compass, a wire cutter, or even a small flame-thrower attachment (for those truly dire situations, of course).

The way I see it, the more we can do to empower the crew of Space Station 14, the better their chances of surviving and even thriving in the face of adversity. And as a welder and fabricator, I can’t think of a more rewarding or meaningful pursuit.

Collaboration and Camaraderie: The Lifeblood of Survival Fabrication

Of course, the work we do as fabricators for Space Station 14 isn’t something we can accomplish alone. It takes a true team effort, with each member of our crew bringing their own unique skills and expertise to the table.

Whether it’s the engineers who provide the technical specifications and design plans, the materials specialists who source the necessary components, or the welders and machinists who turn those plans into reality, we all play a vital role in ensuring the success of our fabrication efforts.

And it’s not just about the technical aspects of the job – the camaraderie and sense of shared purpose that we cultivate amongst our team is just as important. Because when the chips are down, and the crew of Space Station 14 is counting on us to provide the tools they need to survive, we need to be able to trust each other implicitly.

That’s why we’ve worked so hard to foster a culture of collaboration and support within our fabrication team. We’re not just colleagues – we’re a family, bound together by our shared passion for the work we do and the lives we’re entrusted to protect.

The Weld Fab: Forging the Future of Survival Fabrication

At the end of the day, the work we do as fabricators for Space Station 14 isn’t just about creating tools and weapons – it’s about forging the future of survival in the final frontier.

And that’s why I’m proud to be a part of The Weld Fab, a leading provider of welding and fabrication solutions for the space industry and beyond. With our cutting-edge equipment, our highly skilled team, and our unparalleled commitment to quality and innovation, we’re constantly redefining the boundaries of what’s possible when it comes to survival fabrication.

Whether it’s developing new alloys that can withstand the rigors of space, perfecting our welding techniques to create even stronger and more durable tools, or collaborating with the crew of Space Station 14 to anticipate their ever-evolving needs, we’re always striving to stay one step ahead of the game.

So if you’re looking for a welding and fabrication partner that can help you conquer even the most daunting challenges, look no further than The Weld Fab. Because when it comes to forging the future of survival in the final frontier, we’re the ones you can count on.