As an experienced welder and metal fabricator, I’ve seen firsthand how the right tools can make all the difference in the quality and efficiency of our work. Over the years, I’ve relied on a variety of equipment, from heavy-duty welding positioners to lightweight, precision-engineered jigs. But the most exciting developments I’ve witnessed in recent years have been the advancements in 3D printed welding accessories.

The Evolution of Welding Positioners

When I first started out in this industry, welding positioners were quite rudimentary. They’d get the job done, but often required a lot of manual adjustment and repositioning to get the workpiece in the optimal orientation. This not only slowed down the welding process, but it also put a lot of strain on my body, leading to aches and pains after long shifts.

However, as technology has progressed, welding positioners have undergone a remarkable transformation. Nowadays, we have access to highly advanced positioning equipment that can seamlessly integrate with robotic welding cells, maximizing productivity and minimizing manual labor.

The Benefits of Automated Positioning

One of the key advantages of modern welding positioners is their ability to automate the repositioning of the workpiece. Gone are the days of struggling to maneuver heavy components into the perfect angle for welding. With the push of a button or the tap of a touchscreen, these positioners can rotate, tilt, and adjust the workpiece with precision, ensuring that we can access even the most hard-to-reach areas without straining our backs or putting ourselves at risk of injury.

This automation not only saves us time and effort, but it also helps to improve the overall quality of the welds. By maintaining consistent positioning and orientation, we’re able to achieve a more uniform heat input and better control the flow of the weld pool, resulting in stronger, more aesthetically pleasing seams.

The Rise of 3D Printed Welding Accessories

While the advancements in welding positioners have been a game-changer, the real revolution in our industry has been the emergence of 3D printed welding accessories. These custom-designed tools and fixtures have truly transformed the way we approach our work.

Enhancing Ergonomics with 3D Printed Jigs

One of the most significant benefits of 3D printed welding jigs is their ability to enhance ergonomics. By designing these fixtures to perfectly fit the contours of the workpiece and the operator’s hands, we can reduce the strain on our muscles and joints, allowing us to work more comfortably for longer periods.

For example, I recently worked on a project where we needed to weld a series of complex, irregularly shaped components. Rather than relying on off-the-shelf jigs that didn’t quite fit the bill, we opted to design and 3D print our own custom fixtures. These jigs not only provided a secure and stable platform for the workpieces, but they also featured ergonomic handles and support points that perfectly aligned with the natural movements of my hands and arms.

As a result, I was able to complete the welding tasks with significantly less fatigue and discomfort compared to previous projects that utilized more generic positioning equipment. The reduced physical strain not only made the work easier on my body, but it also helped me maintain a higher level of focus and precision throughout the entire process.

Customizing for Specific Applications

In addition to enhancing ergonomics, 3D printed welding accessories also allow us to tailor our tools to the specific needs of each project. Whether it’s a complex assembly that requires a specialized jig or a unique application that calls for a custom positioner, these 3D printed solutions provide us with the flexibility to adapt our equipment to the task at hand.

I recently worked on a job where we needed to weld a series of long, thin components that were prone to warping during the welding process. Traditional welding positioners simply weren’t up to the task, as they lacked the precision and control needed to maintain the workpieces’ delicate alignment.

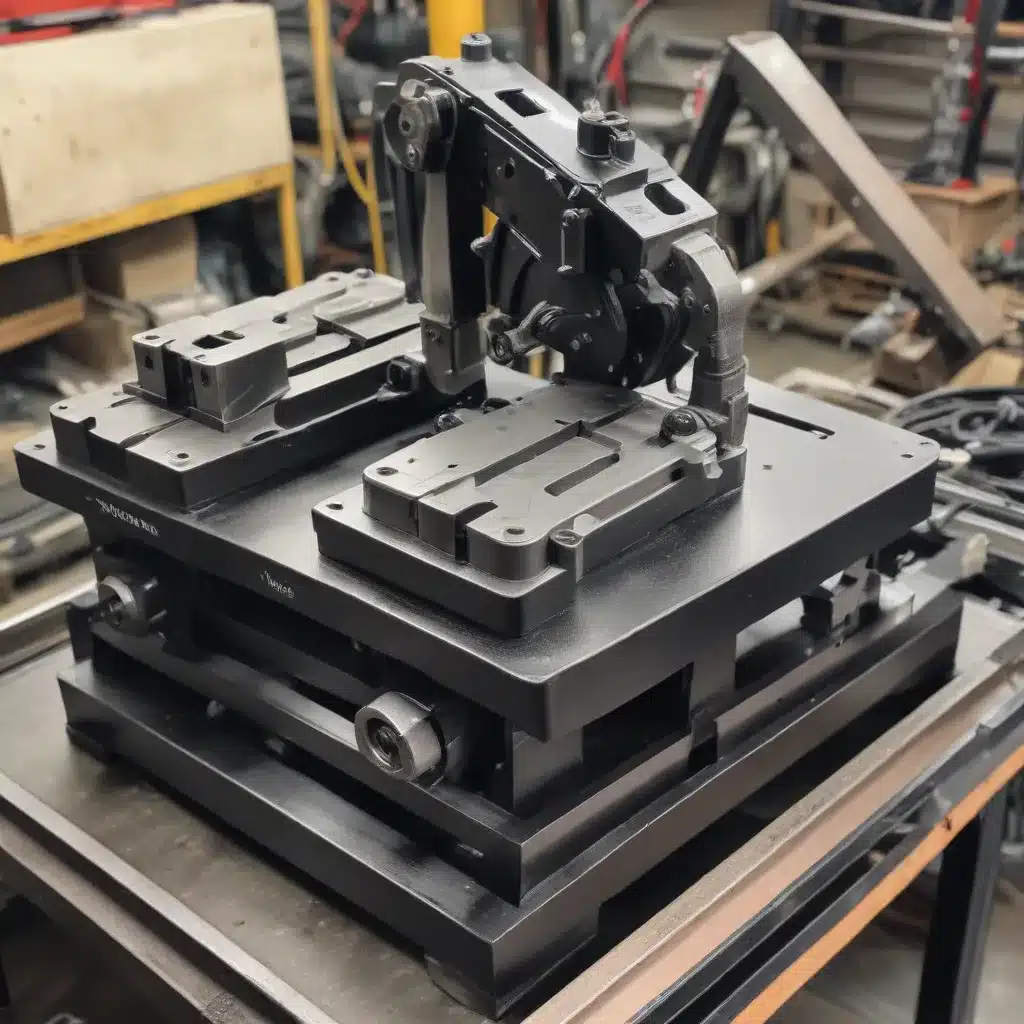

However, by designing and 3D printing a custom positioner, we were able to create a solution that perfectly matched the geometry and requirements of the project. The positioner featured multiple axes of rotation and precise positioning mechanisms that allowed us to carefully control the orientation of the workpieces, minimizing distortion and ensuring consistent, high-quality welds.

The Future of Welding and Fabrication

As I look to the future, I’m incredibly excited about the continued advancements in welding technology and the role that 3D printed accessories will play in shaping our industry. I can envision a time when every welding and fabrication shop will have a 3D printer on-site, allowing us to rapidly prototype and manufacture customized tools and fixtures tailored to the unique demands of each project.

Embracing the Power of Collaboration

One of the most exciting aspects of this emerging technology is the opportunity for collaboration and knowledge-sharing. By connecting with other welders and fabricators, we can exchange ideas, share best practices, and collectively push the boundaries of what’s possible with 3D printed welding accessories.

Imagine a scenario where a welder in California designs a revolutionary jig that dramatically improves the ergonomics of a specific welding task. With the power of 3D printing and online file-sharing, that design could be instantly accessible to welders across the country, allowing them to replicate the benefits of the innovation and further refine the concept.

This collaborative approach not only fosters innovation but also helps to elevate the entire welding and fabrication industry. By sharing our knowledge and insights, we can collectively raise the bar for quality, efficiency, and safety, ensuring that our craft continues to evolve and thrive.

Embracing the Future with Confidence

As I reflect on the remarkable advancements I’ve witnessed in my career, I can’t help but feel a sense of excitement and optimism for the future of our industry. With the power of 3D printing, we have the ability to create customized tools and fixtures that not only improve our productivity but also enhance our overall well-being and job satisfaction.

So, if you’re a fellow welder or fabricator, I encourage you to embrace this exciting new frontier. Explore the capabilities of 3D printing, collaborate with your peers, and challenge yourself to find innovative solutions that push the boundaries of what’s possible. After all, it’s this spirit of innovation that has always been the driving force behind the success and continued evolution of The Weld Fab.