As a seasoned welder and metal fabricator, I’ve witnessed the industry evolve over the years, with each new development pushing the boundaries of what’s possible. One technique that has particularly captivated my interest is electromagnetic pulse forming, a revolutionary approach to shaping and joining metals. In this article, I’ll share my personal experiences and insights on how this cutting-edge technology is transforming the world of welding and fabrication.

The Power of Electromagnetic Pulse Forming

At the heart of electromagnetic pulse forming lies the ability to harness the power of intense, transient magnetic fields. By delivering a brief, high-intensity current through a specialized coil, known as an actuator, we can generate a powerful magnetic field that interacts with the conductive workpiece, creating a dramatic and rapid deformation.

The fascinating part is that this process happens without any direct physical contact between the coil and the workpiece. The magnetic field induces an opposing current within the metal, causing it to be repelled and launched at incredible speeds, often exceeding 100 meters per second. This contactless approach opens up a world of possibilities, allowing us to form, shape, and join materials in ways that were previously unimaginable.

Unveiling the Versatility

One of the most impressive aspects of electromagnetic pulse forming is its versatility. This technology can be applied to a wide range of metal fabrication tasks, from forming complex shapes to joining dissimilar materials. Let me share a few examples that have left a lasting impression on me.

Forming Intricate Shapes

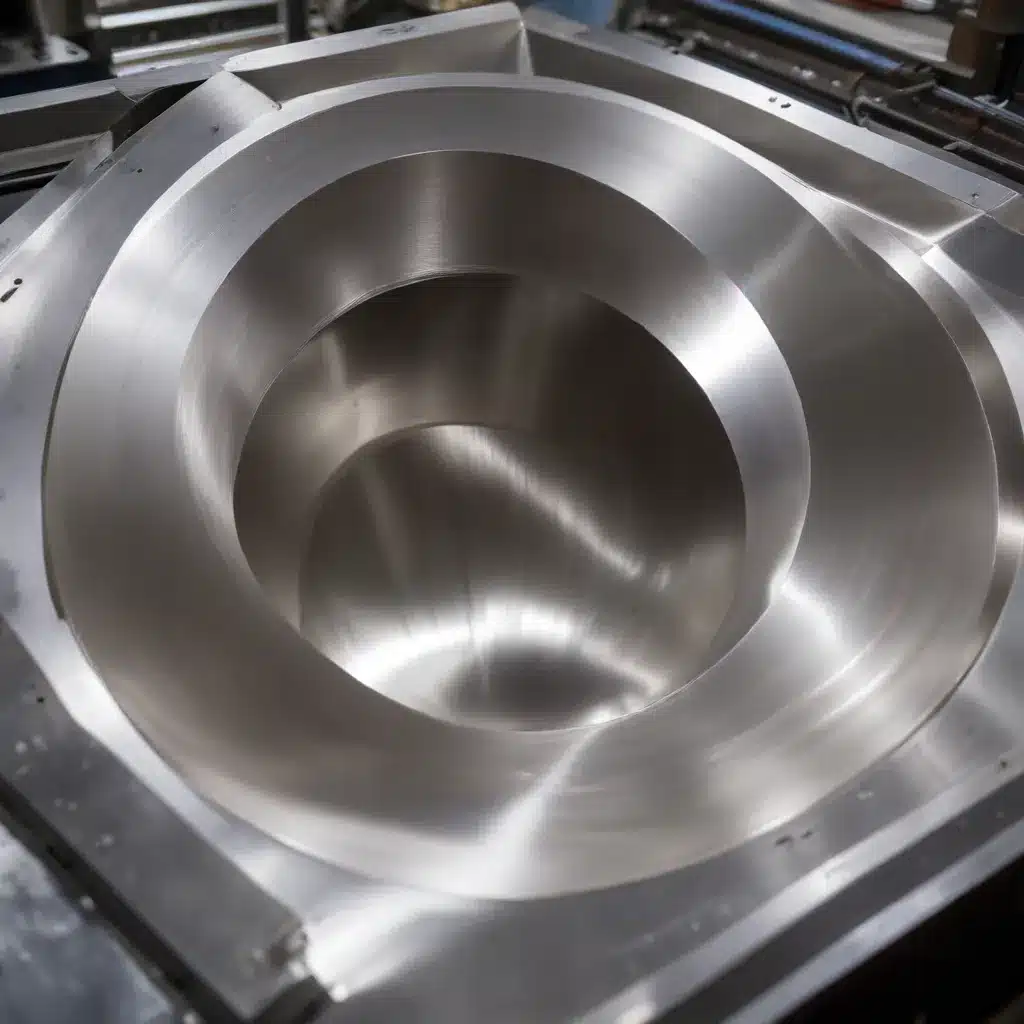

Imagine being able to create complex, contoured parts with just a few milliseconds of intense magnetic field. That’s precisely what electromagnetic pulse forming allows us to achieve. I’ve had the privilege of working on projects where we’ve formed intricate automotive body panels, sculpting the metal into breathtaking designs with unparalleled precision.

The beauty of this process lies in its ability to overcome the limitations of traditional forming methods. Gone are the days of painstakingly crafting dies and molds. Instead, we can simply program the desired shape into the control system, and the electromagnetic actuator takes care of the rest. This not only saves time and resources but also opens up new creative possibilities for our fabrication team.

Joining Dissimilar Materials

One of the most fascinating applications of electromagnetic pulse forming is its ability to join dissimilar materials, such as combining aluminum with steel or titanium with copper. This is a game-changer, as traditional welding techniques often struggle to achieve strong, reliable bonds between these incompatible metals.

The secret lies in the high-speed collision that occurs during the pulse forming process. By accelerating one material towards the other at breakneck speeds, we can create a solid-state weld interface that is free of oxides and impurities. The result is a joint that often outperforms the parent materials, unlocking new avenues for innovative product design and engineering.

Embracing the Advantages

As an experienced welder and fabricator, I can’t help but be in awe of the advantages that electromagnetic pulse forming brings to the table. Let’s dive into some of the key benefits that have made this technology a game-changer in our industry.

Increased Forming Limits

One of the most remarkable aspects of electromagnetic pulse forming is its ability to push the boundaries of what’s possible in metal forming. By harnessing the power of high-speed deformation, we can achieve forming limits that simply couldn’t be reached with conventional methods.

I’ve witnessed firsthand how this technique has allowed us to form parts with significantly reduced springback, minimizing the need for extensive post-processing and secondary operations. The rapid deformation also helps to reduce wrinkling and other common defects, ensuring a consistently high-quality output.

Dimensional Precision and Repeatability

Precision is the name of the game in the world of metal fabrication, and electromagnetic pulse forming delivers on that front. The contactless nature of the process, combined with the lightning-fast deformation, enables us to achieve remarkable dimensional accuracy and repeatability.

Gone are the days of tedious tweaks and adjustments to ensure a perfect fit. With electromagnetic pulse forming, we can reliably reproduce complex shapes and intricate details, time and time again. This level of precision is invaluable in industries such as aerospace, where even the slightest variation can have significant implications.

Reduced Energy Consumption and Cost-Effectiveness

Another remarkable advantage of electromagnetic pulse forming is its energy efficiency and cost-effectiveness compared to traditional forming methods. Conventional processes often require massive, energy-hungry hydraulic presses and dies that consume vast amounts of power and resources.

In contrast, the electromagnetic pulse forming setup is relatively compact and efficient. By using a capacitor bank to store and release the energy in a controlled burst, we can achieve the desired deformation with a fraction of the energy input. This not only reduces our environmental impact but also translates to significant cost savings for our fabrication operations.

Innovating with Electromagnetic Pulse Forming

As an industry leader, I’m constantly on the lookout for innovative ways to push the boundaries of what’s possible in metal forming and welding. Electromagnetic pulse forming has become a key part of our arsenal, and I’m excited to share some of the cutting-edge developments that have captured my attention.

Openable Actuators and Precision Shaping

One of the latest advancements in the field of electromagnetic pulse forming is the development of openable actuators. These specialized coils allow for even greater versatility, as they can be easily placed around the workpiece and then separated, enabling us to form parts with intricate geometries and access hard-to-reach areas.

I’ve had the privilege of working with these openable actuators on projects where we’ve been able to create precise, localized deformations, such as flanging, hemming, and even micro-forming. The ability to control the magnetic field’s shape and intensity with pinpoint accuracy has opened up a whole new realm of possibilities for us.

Hybrid Techniques and Pulsed Laser Welding

But the innovation doesn’t stop there. In our quest to push the boundaries even further, we’ve been exploring the integration of electromagnetic pulse forming with other cutting-edge technologies, such as pulsed laser welding.

Pulsed laser welding is a solid-state collision-based process that uses a short laser pulse to accelerate a flyer material towards a workpiece, achieving velocities up to tens of kilometers per second. By combining this technique with electromagnetic pulse forming, we’ve been able to create incredibly strong, oxide-free welds between dissimilar metals, outperforming the parent materials.

The synergy between these two technologies is truly remarkable, and it’s allowing us to tackle some of the most challenging welding and joining challenges in the industry. The oxide-free, reproducible nature of these welds is a game-changer, and I can’t wait to see how we can further refine and apply this hybrid approach.

Embracing the Future of Metal Fabrication

As I reflect on my experiences in the world of welding and metal fabrication, I can’t help but feel a profound sense of excitement and anticipation. The advancements in electromagnetic pulse forming and its integration with other cutting-edge techniques have truly opened up a new frontier in our industry.

Gone are the days of relying solely on traditional methods. Now, we have the power to shape, join, and manipulate metals in ways that were once unimaginable. And as we continue to push the boundaries of what’s possible, I know that the future of metal fabrication is brighter than ever before.

If you’re as passionate about this industry as I am, I invite you to join me in exploring the endless possibilities that lie ahead. Let’s continue to innovate, experiment, and discover new ways to elevate the art of welding and metal fabrication. Together, we can redefine the very essence of what’s possible, one pulse at a time.