As an experienced welder and metal fabricator, I’ve had the privilege of working with a wide range of materials and techniques over the years. One area that has particularly fascinated me is the field of surface engineering, and within that, the innovative process of laser cladding. In this article, I’ll share my insights and personal experiences on how this remarkable technology can unlock the full potential of metal surfaces, delivering enhanced performance and durability.

The Art of Surface Engineering

In the dynamic world of advanced materials, surface engineering has emerged as a game-changing discipline. By focusing on the intricate details of a material’s surface, we can unlock unprecedented levels of performance and functionality. Whether it’s increasing wear resistance, improving corrosion protection, or enhancing aesthetic appeal, surface engineering has become a crucial tool in the arsenal of countless industries.

As a welder, I’ve seen firsthand the transformative power of these techniques. Gone are the days when a material’s bulk properties were the sole determinant of its suitability. Today, the ability to engineer the surface to meet specific requirements can provide a significant competitive edge. From aerospace to automotive, electronics to biomedical, the demand for high-performance, long-lasting materials has driven the rapid evolution of surface engineering.

Laser Cladding: The Cutting Edge of Surface Modification

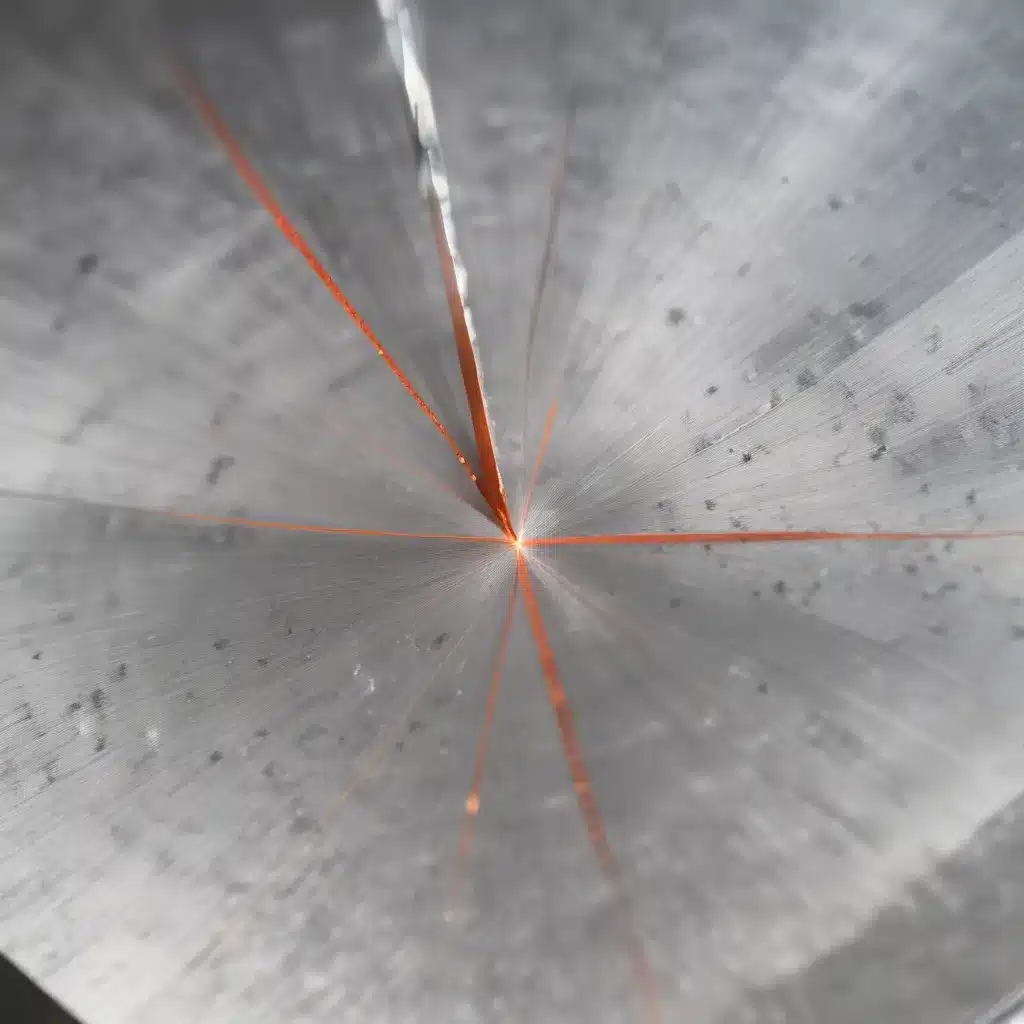

Among the many surface engineering techniques, laser cladding stands out as a true marvel of modern metalworking. This process involves the precise application of a protective or functional layer onto a substrate material, using a high-energy laser beam as the heat source. The result is a seamless, metallurgically bonded coating that can dramatically enhance the surface properties of the underlying component.

What fascinates me most about laser cladding is the level of control and precision it offers. By carefully selecting the cladding material and precisely controlling the laser parameters, we can tailor the properties of the surface to meet the specific needs of the application. Want to boost wear resistance? Laser cladding can do that. Seeking to improve corrosion resistance? The solution lies in the careful application of this technique.

The Science Behind Laser Cladding

The underlying science behind laser cladding is both intricate and captivating. At its core, the process involves the melting and deposition of a powdered or wire-fed material onto the surface of a substrate. The high-energy laser beam melts the cladding material, and as it solidifies, it forms a metallurgical bond with the underlying metal.

This controlled fusion of materials is what sets laser cladding apart from other surface modification methods. Unlike traditional coating techniques, the cladding layer is not simply adhered to the surface; it’s an integral part of the component, sharing the same microstructure and properties. This level of integration is what enables the remarkable improvements in surface performance.

Optimizing Laser Cladding Parameters

As a seasoned welder, I know that the success of any fabrication process lies in the meticulous control of the various parameters involved. Laser cladding is no exception, and the ability to fine-tune these variables is crucial to achieving the desired outcomes.

Some of the critical parameters that we meticulously manage in laser cladding include:

-

Laser Power: The intensity of the laser beam directly impacts the melting and fusion of the cladding material. Adjusting the power ensures the right balance between complete melting and minimal substrate dilution.

-

Cladding Material Composition: The choice of the cladding material, whether it’s a metal alloy, ceramic, or a composite, plays a pivotal role in determining the final surface properties. We carefully select the optimal composition to meet the specific performance requirements.

-

Deposition Rate: The rate at which the cladding material is deposited onto the substrate can significantly influence the quality and integrity of the coating. Too fast, and we risk incomplete fusion; too slow, and the process becomes inefficient.

-

Shielding Gas: The use of a protective shielding gas, such as argon or nitrogen, helps to create an inert atmosphere and prevent oxidation during the cladding process. Maintaining the right gas flow is essential for optimal results.

By mastering the art of manipulating these parameters, we can achieve a level of precision that simply wasn’t possible with traditional surface modification techniques. It’s this attention to detail that allows us to consistently deliver high-performance, durable coatings that exceed the expectations of our clients.

Laser Cladding in Action: Real-World Applications

The versatility of laser cladding is truly astounding, and I’ve had the privilege of witnessing its transformative impact across a wide range of industries. Let me share a few examples of how this technology has unlocked new possibilities for our clients.

In the aerospace sector, we’ve used laser cladding to enhance the wear resistance of critical engine components. By applying a specialized alloy coating, we’ve been able to significantly extend the lifespan of these parts, reducing maintenance costs and ensuring reliable performance even in the harshest operating conditions.

For our automotive clients, laser cladding has become a go-to solution for improving the corrosion resistance of brake components and other high-stress areas. The ability to create a seamless, impervious coating has proven invaluable in protecting against the ravages of salt, chemicals, and harsh environmental factors.

In the biomedical industry, we’ve leveraged the precision of laser cladding to fabricate implants with superior biocompatibility and osseointegration properties. By tailoring the surface chemistry and topography, we’ve been able to enhance the body’s acceptance of these medical devices, improving patient outcomes and reducing the risk of rejection.

These are just a few examples of the transformative potential of laser cladding. As I reflect on these projects, I’m constantly in awe of the level of control and customization this technology affords us. It’s a true testament to the power of surface engineering in unlocking the full potential of advanced materials.

Pushing the Boundaries of Laser Cladding

As an industry veteran, I’ve witnessed the rapid evolution of laser cladding, and I’m excited to see where the future will take us. The ongoing advancements in laser technology, material science, and process control have opened up new horizons, and I’m eager to explore them alongside my colleagues.

One area that particularly intrigues me is the integration of laser cladding with other surface modification techniques, such as shot peening or nitriding. By combining these complementary processes, we can create truly remarkable surface properties that push the boundaries of what was once thought possible.

Another fascinating direction is the exploration of functionally graded coatings, where we can seamlessly transition between different materials and properties within a single cladding layer. Imagine a surface that can simultaneously provide superior wear resistance, corrosion protection, and thermal management – the possibilities are truly endless.

As I look ahead, I’m also excited about the potential of automation and robotic integration in laser cladding. By leveraging these technologies, we can achieve unprecedented levels of precision, consistency, and efficiency, unlocking new realms of productivity and quality.

Embracing the Future of Laser Cladding

As I reflect on my journey as a welder and metal fabricator, I’m acutely aware of the transformative power of surface engineering and the remarkable potential of laser cladding. This technology has not only revolutionized the way we approach material performance but has also ignited a passion within me to constantly push the boundaries of what’s possible.

In the years to come, I envision a future where laser cladding becomes an integral part of the fabrication landscape, seamlessly integrating with other cutting-edge techniques to deliver unparalleled solutions. Whether it’s aerospace, automotive, or biomedical, the ability to engineer surfaces with laser-like precision will be a game-changer, unlocking new levels of innovation and competitive advantage.

As for my own role, I’m committed to staying at the forefront of this dynamic field. I’ll continue to hone my skills, explore new applications, and collaborate with like-minded professionals to unlock the full potential of laser cladding. After all, as a welder, my driving passion has always been to create exceptional, high-quality work – and laser cladding is the perfect vehicle to fulfill that dream.

So, if you’re a fellow fabricator or someone with a keen interest in the world of advanced materials, I invite you to join me on this journey of discovery. Together, let’s unlock the limitless possibilities of laser cladding and redefine the boundaries of what’s achievable in the world of metal fabrication. The future is ours to shape, and I can’t wait to see what we’ll create.