As an experienced welder and metal fabricator, I’ve had the privilege of working with a diverse range of cutting technologies over the years. But one method that has consistently impressed me for its versatility, precision, and clean results is abrasive water jet cutting. Let me share my insights and personal experiences with this remarkable fabrication process.

The Evolution of Water Jet Cutting

Water jet cutting has a rich history, dating back to the early 20th century when the concept of using high-pressure water for cutting was first explored. However, it wasn’t until the 1960s and 1970s that significant advancements were made, leading to the development of modern water jet cutting systems. One of the pioneers in this field was Dr. Norman Franz, who in 1971 patented his innovative high-pressure water jet cutting method.

The introduction of abrasive water jet cutting in the 1980s was a game-changer, allowing for the cutting of even harder materials like stainless steel, titanium, and ceramics. By combining the high-pressure water stream with abrasive particles, such as garnet sand, the cutting power was significantly enhanced, expanding the applications of this technology.

The Anatomy of a Water Jet Cutter

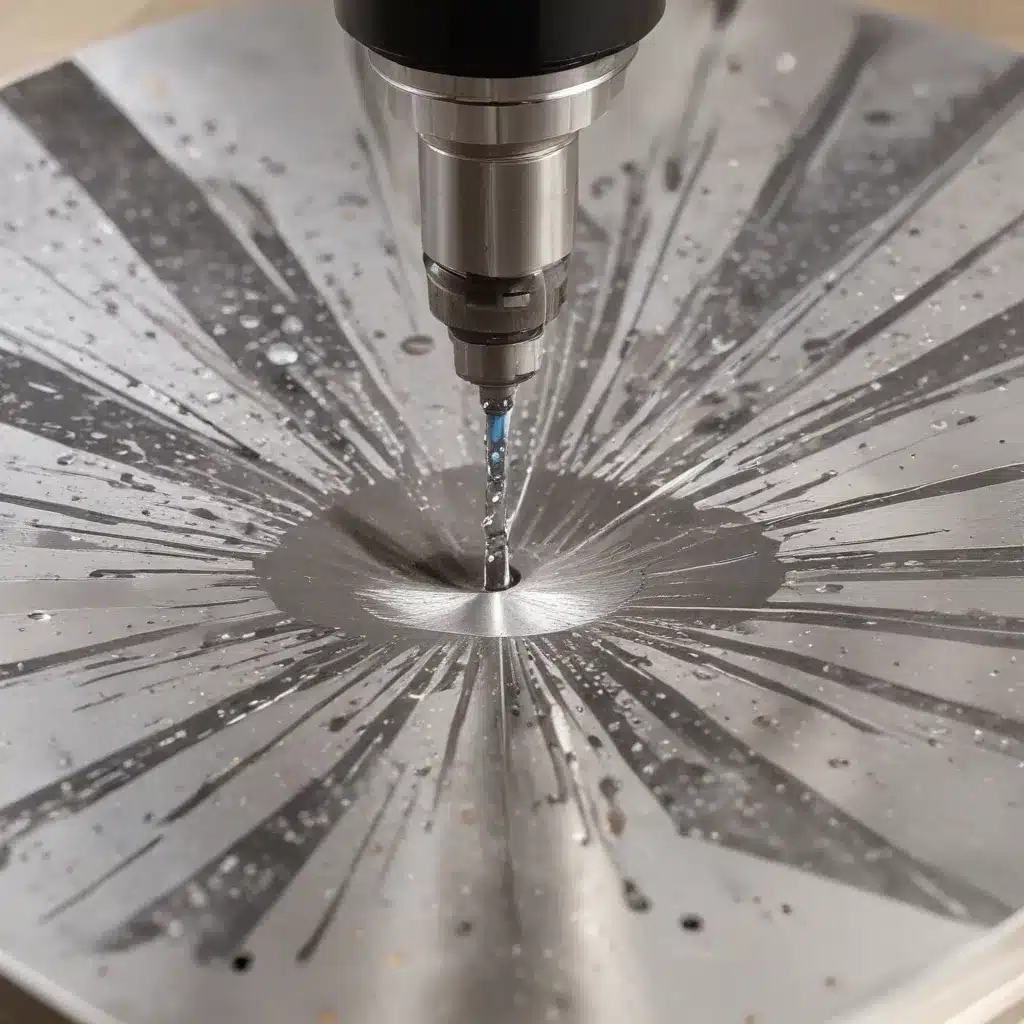

To truly appreciate the precision and capabilities of abrasive water jet cutting, it’s essential to understand the key components that make up a water jet cutting system. At the heart of the operation is the high-pressure pump, which generates the ultra-high pressure water needed to cut through a wide range of materials. These pumps can produce pressures exceeding 90,000 psi, creating a stream capable of cutting with remarkable speed and accuracy.

The cutting table serves as the platform where the materials are secured, ensuring stability and precision during the cutting process. The jet nozzle is where the magic happens – it’s here that the high-pressure water and abrasive particles are combined and focused into a fine, powerful stream for cutting. The abrasive delivery system, X-Y motion system, catcher tank, and water recycling system work in harmony to create a seamless and efficient cutting operation.

Unleashing the Versatility of Abrasive Water Jet Cutting

One of the standout features of abrasive water jet cutting is its ability to handle a diverse range of materials with exceptional precision. From metals like stainless steel and titanium to ceramics, glass, and composites, this technology can tackle even the toughest and most intricate cutting challenges.

The process works by using the kinetic energy of the high-pressure water stream, sometimes combined with abrasive particles, to erode the material along the desired path. Unlike traditional cutting methods that rely on heat, water jet cutting is a “cold” process, preserving the material’s properties and integrity. This makes it ideal for delicate or temperature-sensitive materials, as there’s no risk of thermal distortion or damage.

Precision and Edge Quality: The Water Jet Advantage

What sets water jet cutting apart is its ability to produce remarkably precise and clean cuts, with minimal taper and excellent edge quality. This is achieved through the precise control of various parameters, such as water pressure, nozzle diameter, abrasive type, and feed rate.

By fine-tuning these variables, water jet cutting can deliver cuts with an accuracy range of 0.003 to 0.005 inches, making it a go-to choice for industries that demand the highest levels of precision, such as aerospace, medical devices, and electronics. The clean, burr-free edges produced by this process also eliminate the need for extensive post-processing, saving time and resources.

Precision Cutting Meets Intricate Designs

One of the true standout capabilities of abrasive water jet cutting is its ability to handle even the most intricate and complex designs with ease. The combination of high-pressure water, abrasive particles, and advanced CNC control systems allows for the creation of intricate patterns, shapes, and contours that would be challenging or even impossible to achieve with traditional cutting methods.

Whether you’re looking to fabricate intricate parts for aerospace applications, produce detailed prototypes, or bring your most creative design visions to life, water jet cutting is the solution that can make it a reality. The precision and flexibility of this technology open up a world of possibilities for metal fabricators and designers alike.

Efficiency and Eco-Friendliness: The Water Jet Advantage

In addition to its precision and versatility, water jet cutting also boasts impressive efficiency and environmental benefits. The cold cutting process means there’s no need for coolants or lubricants, which can simplify the overall cutting operation and reduce waste. Furthermore, the water and abrasive particles used in the process can be recycled and reused, minimizing the environmental impact.

Compared to traditional cutting methods that rely on heat, water jet cutting also generates significantly less scrap material, contributing to a more sustainable fabrication process. This efficiency, coupled with the ability to cut a wide range of materials, makes water jet cutting an attractive option for fabricators and manufacturers looking to optimize their processes while prioritizing environmental responsibility.

Overcoming Challenges: Mastering Water Jet Cutting

Of course, as with any advanced fabrication technology, there are some challenges that come with mastering the art of water jet cutting. Maintaining the proper water pressure, nozzle diameter, abrasive type, and feed rate is crucial for achieving the desired results. Additionally, understanding the limitations of the process, such as the maximum material thickness that can be effectively cut, is essential for ensuring successful projects.

But for those of us who have honed our skills in water jet cutting, the sense of accomplishment that comes from creating intricate, precision-cut parts is unparalleled. It’s a testament to the power of technology and the human ingenuity that has driven its evolution.

Choosing the Right Water Jet Cutting Partner

When it comes to water jet cutting, not all fabrication shops are created equal. It’s essential to partner with a team of experts who have a deep understanding of the technology, as well as the experience to push the boundaries of what’s possible.

At [The Weld Fab], we take great pride in our water jet cutting capabilities, leveraging the latest advancements in equipment and software to deliver unparalleled results for our clients. Our team of skilled technicians and engineers work closely with each customer to understand their specific needs and design requirements, ensuring that the final product exceeds their expectations.

Whether you’re in the aerospace, medical, automotive, or any other industry that demands precision and quality, [The Weld Fab] is your trusted partner for water jet cutting solutions. We invite you to explore our capabilities and experience the power of precision fabrication firsthand.

Conclusion: Embracing the Future of Water Jet Cutting

As I reflect on my journey in the world of metal fabrication, I can say with confidence that water jet cutting has been a game-changer. The ability to create intricate designs, cut through a wide range of materials, and do so in an efficient and eco-friendly manner is a testament to the incredible advancements in this technology.

Whether you’re a seasoned fabricator or just starting to explore the possibilities, I encourage you to discover the transformative power of water jet cutting. It’s a technology that has the potential to take your metal fabrication projects to new heights, unlocking a world of creative possibilities and delivering unparalleled precision.

So, what are you waiting for? Let’s dive into the future of water jet cutting together and elevate your fabrication game to new levels of excellence. [The Weld Fab] is here to guide you every step of the way.