As an experienced welder and metal fabricator, I’ve had the privilege of witnessing firsthand the incredible advancements in welding technologies over the years. One technique that has truly revolutionized the industry is Cold Metal Transfer (CMT) welding. This innovative process has opened up a world of possibilities, particularly when it comes to efficiently joining thin-gauge materials.

The Dawn of a New Era in Welding

I remember the early days of my career, where we relied on more traditional welding methods that often struggled with thin, delicate materials. The heat input required would frequently lead to warping, distortion, and uneven results. It was a constant battle to maintain the integrity and visual appeal of our fabricated components. However, everything changed when CMT welding burst onto the scene.

Precision, Efficiency, and Minimal Distortion

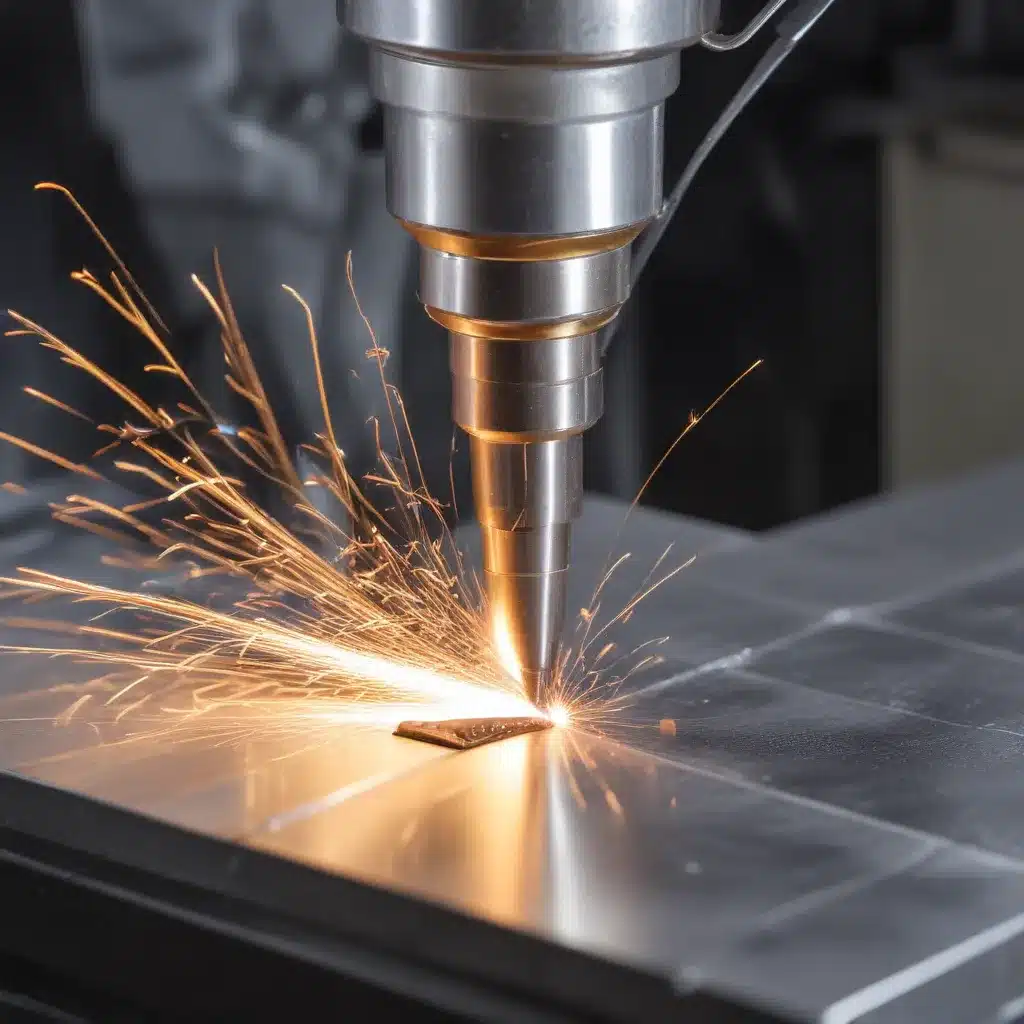

The secret behind CMT welding’s success lies in its precisely coordinated interaction between the welding wire and the power source. This meticulously controlled process allows for the seamless joining of metals with varying thicknesses, all while preserving exceptional strength and structural integrity. What really sets CMT apart is its ability to minimize heat input, which in turn drastically reduces distortion – a game-changer when working with thin, heat-sensitive materials.

One of the standout features of CMT welding is its controlled droplet detachment. This innovative mechanism significantly reduces spatter formation, leading to cleaner welds and less post-weld cleanup. It’s truly remarkable to witness the difference in the final product when compared to traditional welding techniques. The reduced spatter not only enhances the visual appeal but also streamlines the overall fabrication process.

Versatility Across Industries

The adaptability of CMT welding is truly impressive, making it a valuable asset across a wide range of industries. In the automotive sector, this technology shines in body-in-white assembly, where it’s used to join high-strength steel structures with precision and efficiency. In the aerospace industry, CMT welding finds its niche in the fabrication of intricate aluminum structures, leveraging its minimal heat input to ensure the integrity of delicate components.

But the versatility of CMT welding doesn’t stop there. It’s also widely employed in general manufacturing, where welding dissimilar materials and thin-gauge metals is a common challenge. The superior weld quality achieved with this technique is a game-changer, allowing fabricators to tackle projects that were once deemed too complex or risky.

Pushing the Boundaries with RDT Welding

As impressed as I am with the capabilities of standard CMT welding, I’ve recently been introduced to an even more advanced iteration – Retract Droplet Transfer (RDT) welding. This breakthrough technology, developed by Megmeet Welding Technology, takes the principles of CMT welding to new heights, offering unparalleled precision, efficiency, and quality.

The RDT process incorporates a comprehensive range of patented technologies, including ultra-low heat input current waveform, fine-control technology, molten droplet necking prediction technology, and an efficient energy dissipation system. These innovations work in harmony to deliver an even higher level of control and performance compared to traditional CMT welding.

One of the key advantages of RDT welding is its ability to achieve spatter reduction of up to 99%. This is a remarkable feat, considering the already impressive spatter reduction capabilities of CMT welding. The seamless integration of these advanced technologies allows fabricators to produce exceptionally clean welds, minimizing the need for post-weld cleanup and further enhancing the overall efficiency of the process.

Pushing the Boundaries of Thin-Gauge Welding

But the advancements don’t stop there. RDT welding boasts the ability to perform ultra-high-precision, fine back-and-forth wire feeding, with the capability of precise forward and reverse rotations. This level of control allows for the seamless welding of materials as thin as 0.5mm, a feat that was once considered nearly impossible with traditional welding methods.

The RDT process also showcases its superior bridging capability for large gaps and uneven gaps, a common challenge when working with thin-gauge materials. This versatility expands the possibilities for fabricators, allowing them to tackle a wider range of projects with confidence and precision.

The Intelligent Approach to Welding

What truly sets RDT welding apart is its microsecond-level response and multi-node industrial fieldbus control technology. This level of intelligence and dynamic response allows for a significant increase or decrease in current, with the capability of handling both DC and AC outputs. The result is a welding process that is truly responsive to the demands of the project, ensuring consistent quality and reliability.

The incorporation of a newly upgraded LCD system and touchscreen control function further enhances the user experience, making RDT welding a highly intuitive and user-friendly technology. The level of intelligence and control built into this system is truly impressive, and it’s a testament to the ongoing innovations in the welding industry.

Embracing the Future of Fabrication

As I reflect on my experiences in the industry, I’m genuinely excited about the potential of CMT and RDT welding technologies. The precision, efficiency, and versatility they offer have the power to transform the way we approach metal fabrication. Whether you’re working on automotive, aerospace, or general manufacturing projects, these advancements can propel your work to new heights of quality and consistency.

But the true value of these technologies lies not just in their technical capabilities, but in the way they empower us as fabricators. By embracing the reduced heat input, minimal spatter, and ultra-high precision of CMT and RDT welding, we can unlock new possibilities, tackle complex challenges, and deliver exceptional results to our clients.

Elevating the Craft of Welding

As I continue to hone my skills and explore the frontiers of metal fabrication, I’m reminded of the incredible progress our industry has made. From the early days of traditional welding methods to the cutting-edge advancements of CMT and RDT, we’ve come a long way. And with each new development, we have the opportunity to elevate our craft, push the boundaries of what’s possible, and redefine the standards of quality and efficiency.

So, my fellow welders and fabricators, I encourage you to dive into these revolutionary welding techniques, to explore their capabilities, and to unleash the full potential of your metalworking prowess. Together, let’s forge a future where precision, innovation, and exceptional craftsmanship are the cornerstones of our industry. After all, it’s our passion, our expertise, and our unwavering commitment to excellence that will continue to drive the welding and fabrication industry forward.

If you’re ready to experience the transformative power of CMT and RDT welding, I invite you to explore the resources available at https://theweldfab.com/. There, you’ll find a wealth of information, industry insights, and practical guidance to help you harness these cutting-edge technologies and elevate your metalworking capabilities.