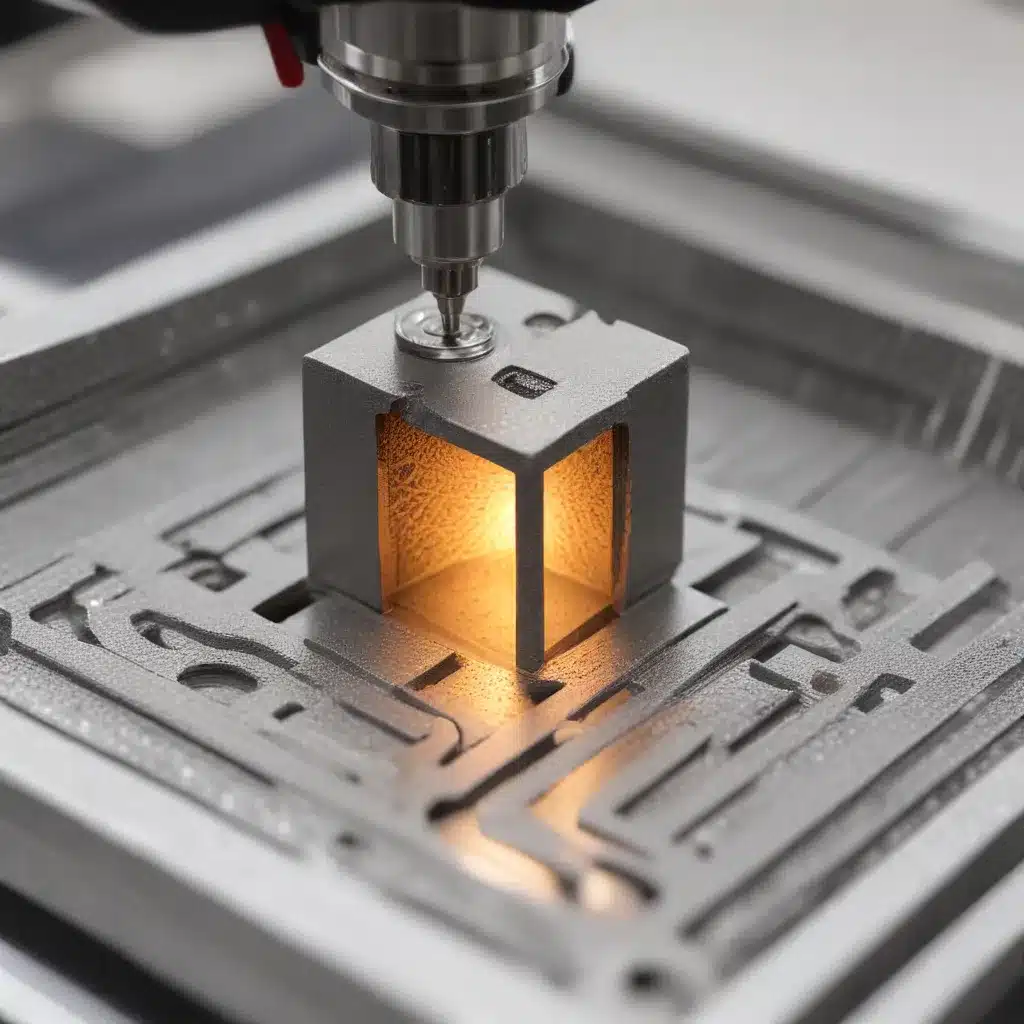

As an experienced welder and metal fabricator, I’ve witnessed the incredible advancements in our industry over the years. One area that has truly captivated my attention is the frontier of metal 3D printing, particularly the technology known as laser powder bed fusion (LPBF). This revolutionary process has the potential to transform the way we approach metalworking, and I’m excited to share my insights and personal experiences with you.

Redefining Productivity and Precision

The metal fabrication landscape is constantly evolving, and the introduction of LPBF systems has been a game-changer. I recently had the opportunity to work with the [EP-M2050], a large-format multi-laser metal AM system that has truly redefined the standards of productivity, versatility, and efficiency.

What sets the [EP-M2050] apart is its impressive array of 36 synchronized lasers, with an optional upgrade to 64 lasers. This multi-laser matrix ensures seamless operation, allowing for unparalleled speed and precision in the manufacturing process. I’ve been amazed by the sheer power and performance of this system, as it can produce large-scale, high-precision components with remarkable consistency.

One of the standout features of the [EP-M2050] is its expansive build volume, measuring an astounding 2050 x 2050 x 1100 mm. With the ability to extend the Z-axis up to 2000 mm, this machine breaks through traditional size constraints, opening up a world of possibilities for fabricating truly groundbreaking parts. Whether it’s for the aerospace industry, automotive manufacturing, or any other demanding sector, the [EP-M2050] has the flexibility to cater to a wide range of printing needs.

Mastering Material Versatility

As a welder, I’ve always been fascinated by the unique properties and characteristics of different metals. The [EP-M2050] embraces this diversity by offering the flexibility to process a variety of materials, including titanium alloys, aluminum alloys, stainless steel, and tool steel. This versatility is a testament to the system’s advanced capabilities, as it can seamlessly handle the specific requirements of each material.

One aspect that particularly impresses me is the [EP-M2050]’s ability to work with layer thicknesses ranging from 20 to 120 microns. This level of precision allows for the creation of highly intricate and detailed components, ensuring that the final product meets the most exacting standards. As a welder, I know firsthand the importance of attention to detail and the impact it has on the overall quality of the work.

Pushing the Boundaries of Productivity

In the world of metal fabrication, productivity is a crucial metric, and the [EP-M2050] is redefining the standards. With its impressive array of 36 (or even 64) synchronized lasers, this system can achieve remarkable manufacturing speeds, allowing me and my team to tackle larger-scale projects with unparalleled efficiency.

What’s truly remarkable is the [EP-M2050]’s ability to maintain consistent quality and precision throughout the entire production process. This is a testament to the advanced software and control systems that seamlessly coordinate the intricate dance of 36 (or 64) lasers, ensuring that every component is produced with the utmost care and attention to detail.

As I’ve worked with this system, I’ve been amazed by its ability to push the boundaries of what’s possible in metal additive manufacturing. The sheer scale and speed of production have allowed us to take on projects that would have been unthinkable with traditional fabrication methods. It’s truly a testament to the innovation and engineering prowess of the team behind the [EP-M2050].

The Importance of Safety and Sustainability

In the world of metal fabrication, safety and sustainability are paramount considerations. The [EP-M2050] addresses these concerns head-on, with a range of features that prioritize the well-being of both the operators and the environment.

One of the standout aspects is the system’s integration with a closed-loop sieving tower. This innovative solution ensures the highest levels of user safety by minimizing the exposure to metal powders and reducing the risk of contamination. It also helps to optimize material usage, reducing waste and promoting sustainability – two values that are deeply important to me as a welder and fabricator.

As I’ve worked with the [EP-M2050], I’ve been impressed by the attention to detail and the focus on creating a safe, efficient, and eco-friendly work environment. It’s clear that the engineers behind this system have put a lot of thought into addressing the unique challenges faced by metal fabricators like myself, and I’m grateful for their commitment to our well-being and the long-term sustainability of our industry.

Embracing the Future of Metal Fabrication

The world of metal fabrication is on the cusp of a transformative revolution, and the [EP-M2050] is at the forefront of this exciting journey. As an experienced welder and metal fabricator, I’ve had the privilege of witnessing firsthand the incredible potential of this technology.

What truly sets the [EP-M2050] apart is its ability to redefine the boundaries of what’s possible in metal additive manufacturing. Whether it’s the sheer scale of the parts we can produce, the precision and consistency of the final components, or the speed and efficiency of the manufacturing process, this system has consistently pushed the envelope, challenging us to rethink our approach to metalworking.

As I reflect on my experiences with the [EP-M2050], I can’t help but feel a deep sense of pride and excitement for the future of our industry. This technology represents a quantum leap forward, opening up new frontiers of possibility and empowering us to tackle challenges that were once thought to be insurmountable.

Conclusion: Welding the Future, One Part at a Time

In the ever-evolving world of metal fabrication, the [EP-M2050] stands as a testament to the power of innovation and the relentless pursuit of excellence. As an experienced welder and metal fabricator, I’ve had the privilege of working with this remarkable system, and I can confidently say that it has transformed the way I approach my craft.

From the awe-inspiring scale and precision of the parts we’ve produced to the unparalleled speed and efficiency of the manufacturing process, the [EP-M2050] has consistently exceeded my expectations. It’s a true game-changer, a revolutionary tool that is redefining the boundaries of what’s possible in the world of metal fabrication.

As I look to the future, I can’t help but feel a sense of excitement and optimism. The [EP-M2050] represents a new era in our industry, one where the impossible becomes possible, and the limits of our creativity are pushed to new heights. And with the unwavering support and commitment of the team behind this remarkable system, I know that the future of metal fabrication is in good hands.

So, if you’re a fellow welder or metal fabricator, I invite you to join me in embracing the frontier of metal 3D printing with laser powder bed fusion. Together, let’s weld the future, one part at a time, and push the boundaries of what’s possible in this dynamic and ever-evolving industry. The [EP-M2050] is here to revolutionize the way we work, and I, for one, can’t wait to see where this journey takes us.