As an experienced welder and metal fabricator, I’ve witnessed firsthand the remarkable evolution of our industry. Gone are the days when welding was simply about fusing metal parts together. Today, we stand at the forefront of a new era, where our craft is integral to the creation of sustainable infrastructure that will power the future.

Embracing the Green Revolution in Construction

The construction industry is undergoing a remarkable transformation, driven by the urgent need to mitigate the environmental impact of our built environment. Across the globe, architects, engineers, and builders are embracing the principles of green construction, seeking to minimize the carbon footprint and maximize the energy efficiency of every structure they create.

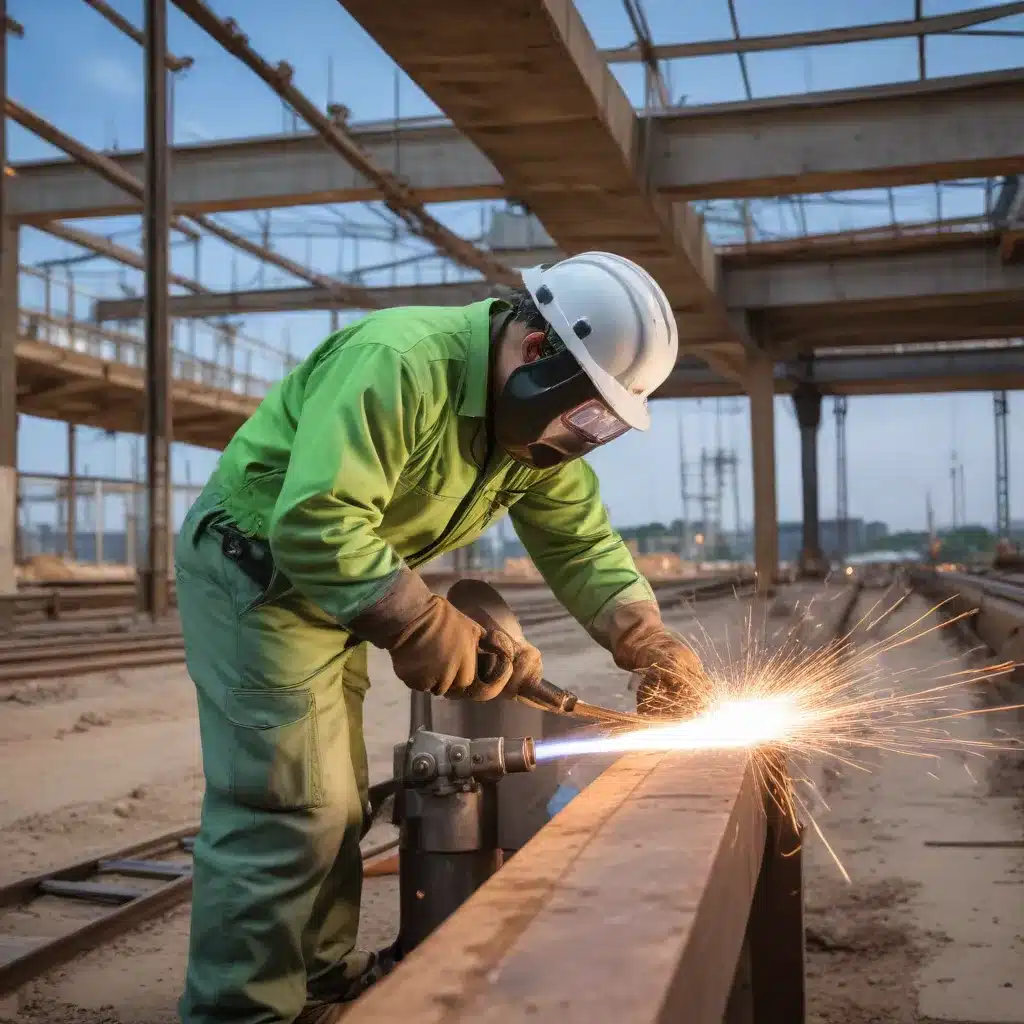

As welders and fabricators, we have a pivotal role to play in this revolution. Our skills and expertise are essential in crafting the durable, high-performance components that form the backbone of sustainable buildings and infrastructure. From reinforced concrete to intricate steel frameworks, our welds are the foundation upon which the future is being built.

But it’s not just about the physical aspects of construction. The very processes we employ in our workshops and on job sites must also evolve to align with the sustainability goals of the industry. This means exploring greener welding techniques, optimizing material usage, and minimizing waste – all while maintaining the uncompromising quality that our clients rightfully demand.

Precision Welding for Superior Fabrication

In the world of welding and fabrication, precision is paramount. Each joint, each seam, and each component must be meticulously crafted to ensure the structural integrity and longevity of the final product. This is especially true in the construction of sustainable infrastructure, where the margin for error is slim and the consequences of failure can be catastrophic.

As an experienced welder, I take pride in my ability to consistently deliver flawless results, time and time again. Through years of honing my craft, I’ve developed a keen eye for detail and a steadfast commitment to quality that permeates every aspect of my work.

One of the keys to my success is the mastery of advanced welding techniques. Whether it’s TIG, MIG, or stick welding, I’ve spent countless hours perfecting my skills, experimenting with different materials and settings to achieve the optimal results. And I’m constantly learning, staying up-to-date with the latest innovations in welding technology and incorporating them into my workflow.

But it’s not just about the technical prowess. Effective welding and fabrication also require a deep understanding of the unique properties and characteristics of the materials we work with. From the tensile strength of steel to the thermal expansion of aluminum, I meticulously analyze every component to ensure that my welds are tailored to its specific needs.

Sustainability in Welding and Fabrication

As the construction industry embraces the principles of sustainability, we as welders and fabricators must also adapt our practices to align with these goals. This means not only optimizing our welding techniques for energy efficiency and emissions reduction but also rethinking the way we approach the entire fabrication process.

One area of focus is the careful selection and utilization of materials. By prioritizing the use of recycled or recyclable materials, we can significantly reduce the carbon footprint of our work, while still maintaining the exceptional quality that our clients demand. Additionally, we must explore ways to minimize waste, whether it’s through more precise cutting patterns, efficient material handling, or innovative recycling processes.

But sustainability in welding and fabrication goes beyond just the materials. It also encompasses the energy-efficient operation of our workshops and the implementation of sustainable practices throughout our entire supply chain. This might include the use of renewable energy sources, the adoption of advanced ventilation and filtration systems, or the optimization of logistics and transportation to minimize our environmental impact.

As an industry leader, I’m proud to be at the forefront of this sustainable transformation. I’ve seen firsthand the remarkable progress that can be achieved when we embrace innovation and a commitment to environmental stewardship. And I’m excited to continue pushing the boundaries, exploring new technologies and techniques that will help us build a greener, more resilient future.

Collaboration and Innovation in Welding

One of the most rewarding aspects of my work as a welder and fabricator is the opportunity to collaborate with a diverse range of professionals, each bringing their unique expertise and perspectives to the table. Whether it’s working closely with engineers to design intricate structural components or partnering with project managers to optimize our fabrication workflows, these cross-disciplinary partnerships have been instrumental in driving innovation and pushing the boundaries of what’s possible.

In the realm of sustainable construction, this collaborative spirit is more crucial than ever. By engaging with architects, material scientists, and sustainability experts, we can develop holistic solutions that address the complex challenges of building a greener future. Through this exchange of ideas and the sharing of best practices, we can unlock new possibilities and uncover innovative welding techniques that will redefine the landscape of sustainable infrastructure.

Moreover, I’m thrilled to see the growing investment in research and development within our industry. As new materials, welding technologies, and fabrication processes emerge, I eagerly dive into the details, eager to understand how these advancements can be leveraged to enhance the quality, efficiency, and environmental impact of our work.

Whether it’s experimenting with advanced coatings that improve corrosion resistance or exploring the use of renewable energy sources to power our workshops, I’m constantly on the lookout for ways to push the boundaries of what’s possible. And by fostering a culture of continuous learning and experimentation, I’m confident that we can continue to lead the charge in the fabrication of sustainable, high-performance infrastructure.

Delivering Exceptional Customer Experiences

At the heart of my work as a welder and fabricator is a deep commitment to delivering exceptional customer experiences. I understand that the projects we undertake are not just about the physical components we create, but the lasting impact they have on the communities they serve. That’s why I strive to go above and beyond, collaborating closely with our clients to ensure their visions are brought to life with the utmost precision and care.

From the initial consultations to the final installation, I make it a priority to maintain open and transparent communication, proactively addressing any concerns or challenges that arise. By fostering a spirit of trust and mutual understanding, I’m able to create a seamless, stress-free experience for our clients, ensuring that their projects are completed on time, within budget, and to their complete satisfaction.

But it’s not just about the end result. I take immense pride in the journey itself, reveling in the opportunity to work closely with our clients, to understand their unique needs and constraints, and to develop customized solutions that exceed their expectations. Whether it’s designing intricate steel frameworks or fabricating specialized equipment, I approach each task with the same unwavering dedication, ensuring that every aspect of the process is executed with the highest standards of quality and craftsmanship.

Ultimately, my goal as a welder and fabricator is to not only deliver exceptional products but to forge lasting partnerships built on trust, transparency, and a shared commitment to excellence. By consistently exceeding our clients’ expectations and fostering a culture of continuous improvement, I’m confident that we can continue to be a trusted and indispensable resource in the construction of sustainable infrastructure for generations to come.

Embracing the Future of Welding and Fabrication

As I look to the future of our industry, I’m filled with a sense of excitement and boundless optimism. The rapid advancements in welding technology, the growing emphasis on sustainability, and the increasing demand for innovative solutions are all converging to create a pivotal moment in the evolution of welding and fabrication.

One area that I’m particularly enthusiastic about is the integration of automation and robotics into our workflows. By leveraging the precision and consistency of these cutting-edge technologies, we can enhance the efficiency and quality of our work, while also minimizing the physical strain on our team. From automated welding systems to advanced material handling equipment, the possibilities for streamlining our operations and elevating our craft are truly limitless.

But it’s not just about the tools and technologies. I’m also excited to see the ongoing investment in sustainability-focused research and development within our industry. As we explore new materials, welding techniques, and fabrication processes that prioritize environmental impact, I’m confident that we can play a pivotal role in shaping a greener, more resilient future for construction.

Whether it’s experimenting with eco-friendly consumables, optimizing energy usage in our workshops, or developing innovative recycling and waste management strategies, I’m eager to be at the forefront of this sustainable transformation. By embracing a culture of continuous learning and a willingness to challenge the status quo, I believe we can redefine the boundaries of what’s possible in the realm of welding and fabrication.

As I reflect on my journey as a welder and fabricator, I’m humbled by the opportunity to play a part in the creation of structures that will stand the test of time and serve as beacons of sustainability for generations to come. And as I look ahead, I’m filled with a renewed sense of purpose, driven by the knowledge that our work is not just about the physical products we create, but the lasting impact we can have on the world around us.

So, let us embrace this exciting new chapter, where the art of welding and the science of fabrication converge to shape a brighter, more sustainable future. Together, let’s push the boundaries of what’s possible, harnessing the power of innovation, collaboration, and an unwavering commitment to quality to build a world that’s greener, more resilient, and truly worthy of our craft.