Precision Perfection: Welding Techniques for the Discerning Fabricator

As an experienced welder and metal fabricator, I’ve encountered my fair share of challenges on the shop floor. From intricate design work to demanding clients, the world of metalworking is nothing if not a constant pursuit of perfection. But over the years, I’ve developed a few tricks up my sleeve – unconventional hacks that have helped me achieve the level of precision and quality that sets my work apart.

Let me tell you, there’s nothing quite like the satisfaction of seeing a project come together seamlessly, with every seam and joint fitting together like a well-oiled machine. It’s the kind of feeling that makes all the hard work and attention to detail worth it. And trust me, I’ve put in the time to hone my craft, pushing the boundaries of what’s possible with metal fabrication.

One of my favorite techniques is something I like to call “the dance.” It’s all about finding that perfect rhythm between the heat of the weld and the steady, controlled movements of the torch. It’s a delicate balance, to be sure, but when you get it right, the result is a flawless bead that seems to flow effortlessly across the surface of the metal.

Now, I know what you’re thinking – “Yeah, right, easy for you to say. I can barely keep a straight line going.” But trust me, with a little practice and the right approach, anyone can master the art of precision welding. It’s all about developing a keen eye, a steady hand, and an unwavering dedication to getting it right.

Mastering the Art of Metal Shaping

Of course, welding is only one part of the equation when it comes to metal fabrication. The true magic happens when you start shaping and forming the raw material into something truly magnificent. And let me tell you, I’ve got a few tricks up my sleeve when it comes to that as well.

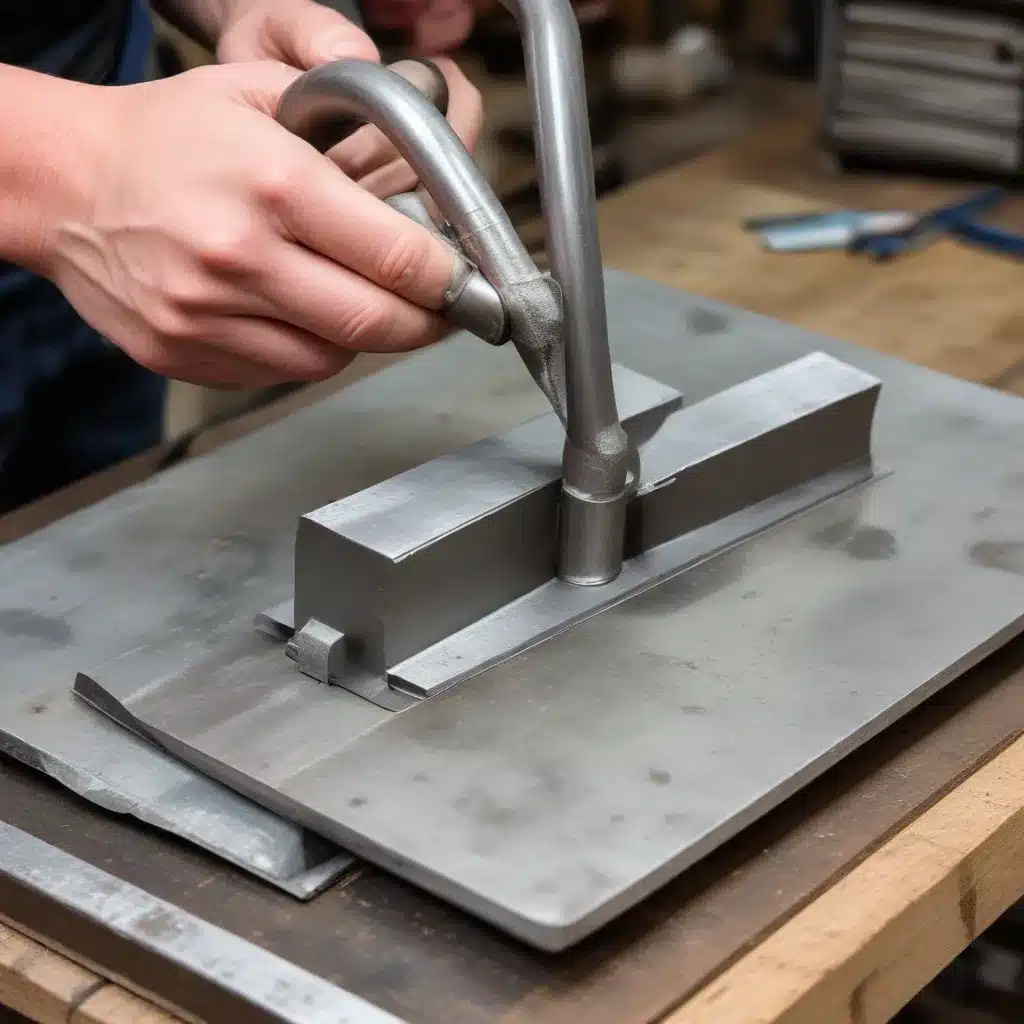

One of my favorite techniques is what I call “the gentle persuasion.” It’s all about using a combination of carefully placed hammer blows and strategic bending to coax the metal into the desired shape. It’s a delicate dance, to be sure, but the results can be absolutely breathtaking.

Now, I know what you’re thinking – “Okay, so you’re a metal whisperer. What’s the big deal?” But the truth is, there’s an art to this kind of precision metalworking that goes far beyond just brute force. It’s about understanding the material, anticipating its behavior, and working with it in a way that brings out its full potential.

And let me tell you, when you get it right, the feeling is unbeatable. There’s something deeply satisfying about taking a piece of raw metal and transforming it into a work of art, with every curve and contour perfectly executed. It’s the kind of thing that makes you want to stand back and admire your handiwork, knowing that you’ve put in the time and effort to truly master your craft.

Embracing the Unconventional: Fabrication Hacks for the Discerning Welder

But of course, as any seasoned fabricator knows, the road to perfection is rarely a straight and narrow one. There are always new challenges to overcome, new techniques to master, and new ways to push the boundaries of what’s possible.

That’s why I’m always on the lookout for unconventional hacks and tricks that can help me achieve the level of precision and quality that I demand. And let me tell you, some of the most valuable insights I’ve gained over the years have come from the most unexpected places.

Take, for example, the time I stumbled upon a old-school welding trick that involved using a damp cloth to control the heat of the weld. At first, I was skeptical – I mean, who in their right mind would think to put water near a white-hot metal joint? But sure enough, when I gave it a try, the results were nothing short of amazing. The cloth helped to keep the weld cool and even, ensuring a flawless finish every time.

Or what about the time I discovered the magic of using a specialized jig to hold delicate metal parts in place during the fabrication process? It was a game-changer, allowing me to achieve levels of precision that I’d never even dreamed of before. And the best part? It was a simple, low-tech solution that anyone could implement with a little creativity and elbow grease.

These are the kinds of hacks and tricks that I live for. They’re the little nuggets of wisdom that can make all the difference in the world when you’re working with metal, and they’re the kinds of things that you just won’t find in any textbook or training manual.

The Pursuit of Perfection: The Weld Fab Way

At the end of the day, that’s what it’s all about for me – the never-ending pursuit of perfection. It’s a journey that’s filled with challenges and setbacks, to be sure, but it’s also one that’s immensely rewarding. Because when you finally achieve that elusive level of precision, when every weld is flawless and every curve is perfectly executed, there’s simply nothing else like it.

And that’s why I love what I do. It’s a constant challenge, a never-ending quest to push the boundaries of what’s possible. And let me tell you, there’s nothing more satisfying than seeing the look on a client’s face when they realize that they’re working with a true master of the craft.

So if you’re a fellow welder or fabricator out there, I encourage you to embrace the unconventional, to seek out those little hacks and tricks that can help you take your work to the next level. Because at the end of the day, that’s what it’s all about – pushing the boundaries, challenging the status quo, and always striving for that perfect, seamless finish.

After all, that’s the The Weld Fab way.

Unleashing the Power of Metal: Innovative Fabrication Techniques

As a seasoned welder and metal fabricator, I’m constantly in awe of the sheer power and versatility of the materials I work with. From the gleaming stainless steel to the rugged carbon fiber, there’s just something about the way these materials respond to the heat and pressure of my tools that never ceases to impress me.

But it’s not just about the raw power of the metal – it’s about harnessing that power and channeling it into something truly remarkable. And that’s where the real magic happens, in the realm of innovative fabrication techniques that push the boundaries of what’s possible.

Take, for example, the art of precision welding. It’s a skill that requires a delicate touch and an unwavering eye for detail, but when executed correctly, the results can be truly breathtaking. I’m talking about welds that are so clean and seamless, they might as well have been carved from a single piece of metal.

Of course, achieving that level of precision isn’t easy. It takes years of practice, a deep understanding of the materials, and a keen eye for the nuances of the welding process. But for me, it’s all about the challenge – the thrill of pushing myself to the limit and discovering new ways to coax the perfect weld out of even the most stubborn of metals.

And it’s not just welding, either. There’s the art of metal shaping, where I use a combination of carefully placed hammer blows and strategic bending to transform raw material into something truly extraordinary. It’s a dance, really, a carefully choreographed interplay between the metal and my tools, and when I get it right, the results are simply breathtaking.

Embracing the Unconventional: Fabrication Hacks for the Modern Metalworker

But of course, as any seasoned fabricator will tell you, the road to perfection is rarely a straight and narrow one. There are always new challenges to overcome, new techniques to master, and new ways to push the boundaries of what’s possible.

That’s why I’m always on the lookout for unconventional hacks and tricks that can help me achieve the level of precision and quality that I demand. And let me tell you, some of the most valuable insights I’ve gained over the years have come from the most unexpected places.

Take, for example, the time I stumbled upon an old-school welding trick that involved using a damp cloth to control the heat of the weld. At first, I was skeptical – I mean, who in their right mind would think to put water near a white-hot metal joint? But sure enough, when I gave it a try, the results were nothing short of amazing. The cloth helped to keep the weld cool and even, ensuring a flawless finish every time.

Or what about the time I discovered the magic of using a specialized jig to hold delicate metal parts in place during the fabrication process? It was a game-changer, allowing me to achieve levels of precision that I’d never even dreamed of before. And the best part? It was a simple, low-tech solution that anyone could implement with a little creativity and elbow grease.

These are the kinds of hacks and tricks that I live for. They’re the little nuggets of wisdom that can make all the difference in the world when you’re working with metal, and they’re the kinds of things that you just won’t find in any textbook or training manual.

Embracing the Art of Metal Fabrication

But of course, as any seasoned fabricator will tell you, the true magic of metalworking isn’t just about the technical prowess. It’s about the art of it all – the way you can take a raw, unforgiving material and transform it into something truly beautiful and functional.

For me, that’s what it’s all about – the endless possibilities that lie within the realm of metal fabrication. Whether it’s crafting a sleek, modern sculpture or designing a one-of-a-kind piece of furniture, the process is always exciting, always challenging, and always immensely rewarding.

And that’s why I love what I do. It’s a constant pursuit of perfection, a never-ending quest to push the boundaries of what’s possible. And let me tell you, there’s nothing more satisfying than seeing the look on a client’s face when they realize that they’re working with a true master of the craft.

So if you’re a fellow welder or fabricator out there, I encourage you to embrace the unconventional, to seek out those little hacks and tricks that can help you take your work to the next level. Because at the end of the day, that’s what it’s all about – pushing the boundaries, challenging the status quo, and always striving for that perfect, seamless finish.

After all, that’s the The Weld Fab way.

Crafting Excellence: The Weld Fab Approach to Metal Fabrication

At The Weld Fab, we’re not just in the business of metalworking – we’re in the business of crafting excellence. It’s a philosophy that permeates every aspect of what we do, from the moment we first lay eyes on a new project to the final, triumphant unveiling of the finished product.

You see, for us, it’s not enough to simply churn out functional metal pieces. We’re driven by a relentless pursuit of perfection, a desire to push the boundaries of what’s possible and to create something truly extraordinary. And that’s where the magic happens – in the endless possibilities that lie within the realm of metal fabrication.

Whether it’s designing a sleek, modern sculpture or crafting a one-of-a-kind piece of furniture, we approach every project with the same unwavering dedication and attention to detail. We’re not just welders or fabricators – we’re artists, problem-solvers, and visionaries, each of us bringing our own unique perspective and skill set to the table.

And it’s that collaborative spirit, that constant striving for excellence, that sets us apart from the rest. Because at the end of the day, it’s not just about the final product – it’s about the journey, the challenges, and the triumphs that we experience along the way.

So if you’re looking for a fabrication partner that truly understands the art of metalworking, look no further than The Weld Fab. We’re not just in the business of creating beautiful, functional pieces – we’re in the business of crafting excellence, one weld and one bend at a time.