Mastering the Art of Friction Stir Welding

As an experienced welder and metal fabricator, I’ve seen my fair share of welding techniques come and go over the years. But one process that has truly captivated my attention is friction stir welding (FSW). This innovative solid-state joining method allows us to create strong, high-quality welds without the intense heat associated with traditional welding processes.

Let me take you on a journey through the world of friction stir welding and share the insights I’ve gained from my time in the industry. This isn’t just another welding technique – it’s a game-changer that’s transforming the way we think about joining metals.

The Science Behind Friction Stir Welding

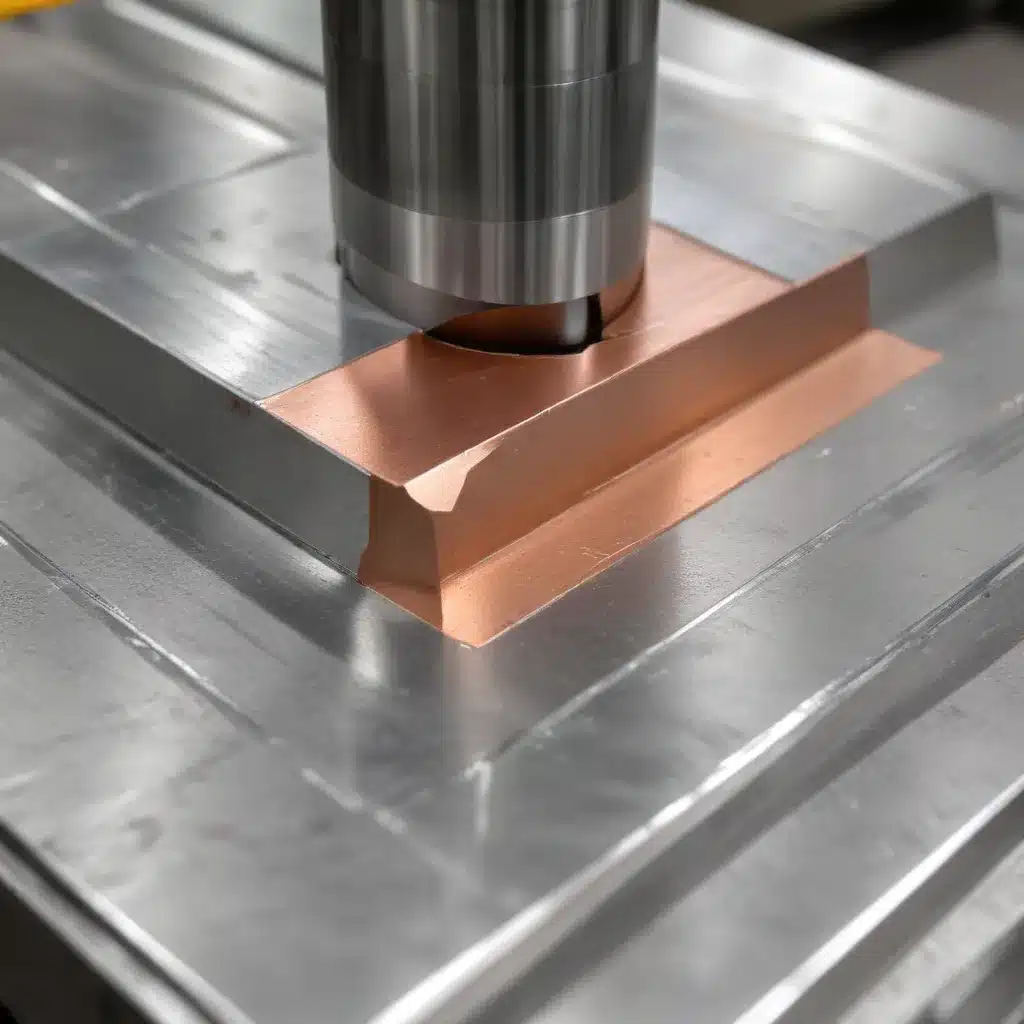

Friction stir welding is a bit like a dance between the workpiece and a non-consumable tool. As the tool rotates and traverses along the joint line, it generates heat through friction with the metal. This heat softens the material, allowing the tool to mechanically intermix the two pieces and forge them together under immense pressure.

The beauty of this process is that it never reaches the melting point of the metals being joined. Instead, it relies on the heat and pressure to create a solid-state bond, resulting in a stronger, more uniform weld with minimal distortion. It’s almost like the metals are being gently coaxed into a permanent embrace, rather than being forced together under the intense heat of a traditional arc or gas welding process.

One of the key advantages of FSW is its ability to join dissimilar metals that would be challenging or impossible to weld using conventional methods. Imagine seamlessly combining aluminum and steel, or even materials like copper and titanium, without the risk of cracking or other defects. This opens up a world of new possibilities for engineers and fabricators working on innovative projects.

Unlocking the Potential of FSW

As I mentioned, I first encountered friction stir welding back in the early 90s while working at a defense contractor. I remember being absolutely mesmerized by the sight of the tool gently stirring the metal, almost as if it were mixing thick peanut butter. The results were nothing short of remarkable – the welds were remarkably strong and consistent, with no visible signs of distortion or defects.

Since then, I’ve had the privilege of working with FSW on a variety of applications, from aerospace components to automotive parts. And let me tell you, the potential of this technology is truly limitless. Just imagine the impact it could have on industries like marine, rail, and even renewable energy, where the ability to join dissimilar metals can unlock new design possibilities and enhance product performance.

One of the most fascinating aspects of FSW is its ability to produce welds that are virtually indistinguishable from the original base material. The mechanical intermixing and forging process results in a seamless, high-strength joint that often outperforms the parent metals in terms of tensile strength and fatigue life. It’s like magic, really – you can’t even tell where the weld begins and ends!

The Craft of Friction Stir Welding

Of course, as with any welding technique, mastering the art of friction stir welding takes time, practice, and a keen eye for detail. It’s not just about cranking up the tool speed and plowing through the workpiece. No, my friends, there’s a delicate balance of parameters that must be carefully dialed in to achieve the perfect weld.

One of the critical factors is the tool design itself. The shape, size, and materials used in the tool can have a significant impact on the heat generation, material flow, and overall weld quality. I’ve worked with a variety of tool designs over the years, each with their own unique strengths and applications. It’s like an artist selecting the perfect brush for a masterpiece – the tool is an extension of the welder’s skill and creativity.

But the real magic happens when you combine the right tool with the perfect set of welding parameters. Things like rotational speed, traverse rate, tilt angle, and downward force all play a crucial role in ensuring a high-quality, consistent weld. And let me tell you, it’s not as simple as just cranking up the speed and hammering through the joint. No, it takes a keen eye, a steady hand, and a deep understanding of the metal’s behavior to get it just right.

I remember one particularly challenging project where we were tasked with joining some thick, high-strength aluminum alloy panels for an aerospace application. The tolerances were tight, and the customer expected nothing less than perfection. After countless hours of experimentation and fine-tuning, we finally dialed in the perfect set of parameters and produced some of the most flawless welds I’ve ever seen. The sense of pride and accomplishment was palpable, and it’s moments like those that make this craft so rewarding.

Embracing the Future of Welding

As I look to the future, I can’t help but feel excited about the endless possibilities of friction stir welding. This technology is truly on the cusp of a revolution, with advancements in tools, equipment, and process control that are pushing the boundaries of what’s possible.

Just imagine the impact it could have on industries like aerospace, where the ability to join dissimilar metals can lead to lighter, more fuel-efficient designs. Or how about the marine sector, where FSW could be used to create stronger, more corrosion-resistant structures for ships and offshore platforms? The possibilities are truly endless, and I can’t wait to see what the next generation of welders and fabricators will achieve with this incredible process.

But it’s not just about the technical advancements – it’s also about the way we approach the craft of welding as a whole. With friction stir welding, we’re not just joining metals; we’re pushing the boundaries of what’s possible, redefining the very nature of how we think about fabrication. It’s a testament to the ingenuity and creativity of our industry, and I couldn’t be more proud to be a part of it.

So, if you’re a fellow welder or metal fabricator, I invite you to join me on this journey of exploration and discovery. Let’s dive deeper into the world of friction stir welding, unlocking its secrets and pushing the limits of what we can achieve. After all, it’s not every day that we get the chance to be part of a true revolution in our craft. The future is ours to shape, and I can’t wait to see what we’ll create together.