As an experienced welder and metal fabricator, I’ve seen my fair share of corrosion challenges in the industry. Over the years, I’ve had to tackle everything from stubborn rust to aggressive chemical attacks, all while ensuring the structural integrity of critical equipment. That’s why I’m excited to share my insights on the innovative weld overlay cladding techniques that are revolutionizing the way we approach corrosion protection.

The Challenges of Corrosion in Heavy Industry

Anyone who’s worked in the heavy industry, whether in power generation, manufacturing, or processing, knows that corrosion is a constant battle. It’s a relentless enemy that can quickly compromise the reliability and lifespan of even the most robust equipment.

Take boiler systems, for example. The harsh operating conditions, with scorching temperatures and corrosive flue gases, can quickly eat away at the metal surfaces, leading to leaks, failures, and costly downtime. Traditional solutions like refractory linings have their limitations, often degrading over time and allowing the underlying steel to succumb to corrosion.

I’ve seen firsthand how this can impact operations. I remember working on a waste-to-energy boiler that was experiencing severe fireside corrosion above the refractory lining. The plant was facing the prospect of premature tube failures and constant maintenance headaches. Something had to be done.

The Rise of Weld Overlay Cladding

That’s where the breakthrough of weld overlay cladding came into play. In the 1980s, the use of Alloy 625 weld overlay started to gain traction as a highly effective solution for corrosion protection in boilers and other industrial equipment.

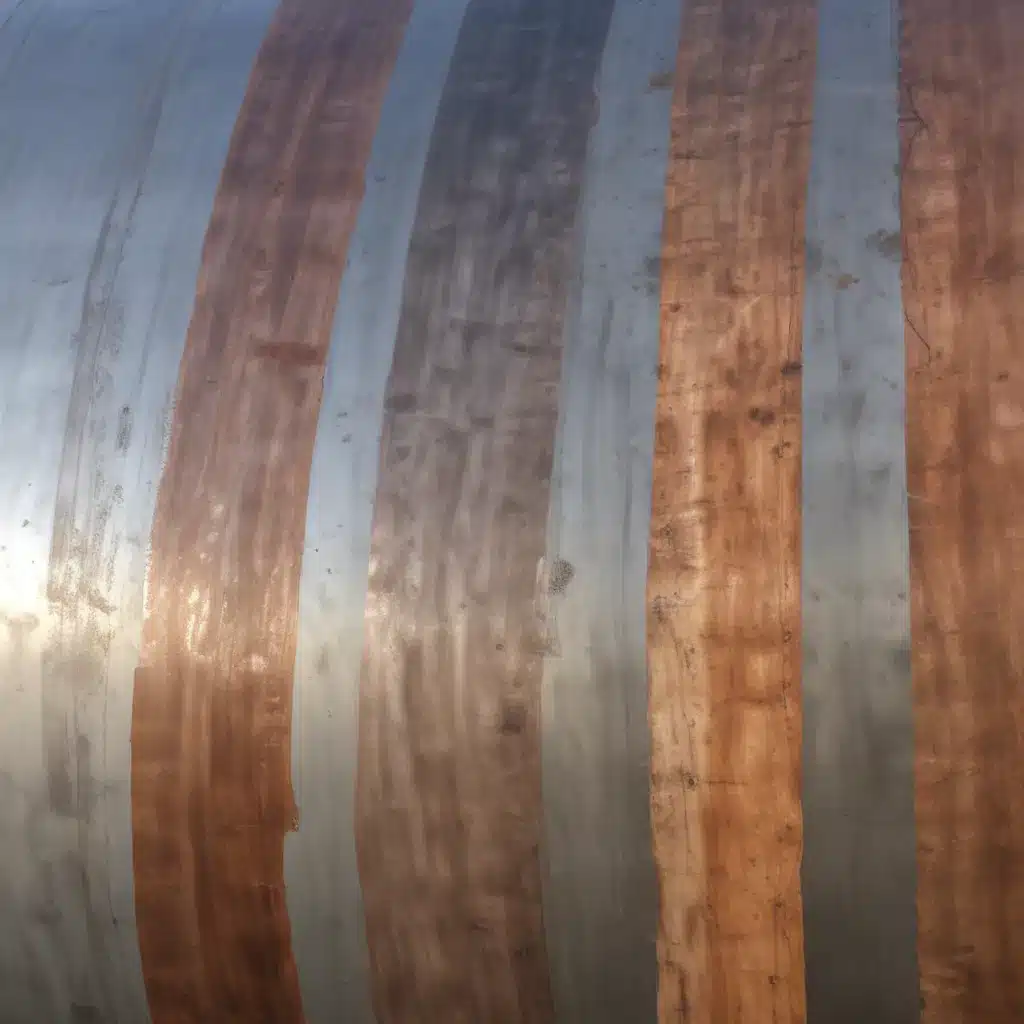

The process involves applying a thin layer of the corrosion-resistant alloy directly onto the base metal, creating a protective barrier that can withstand even the most harsh environments. The beauty of this approach is that it doesn’t require a complete replacement of the underlying structure – it’s a targeted, cost-effective solution that can extend the lifespan of critical components.

I’ve had the privilege of working on numerous projects where weld overlay cladding has made a dramatic difference. One notable example was a boiler that had been plagued by premature degradation of the shop-applied Alloy 625 weld overlay. The plant operators brought us in to address the issue, and we were able to apply a high-velocity thermal spray (HVTS) cladding directly on top of the existing overlay.

The results were nothing short of remarkable. After 10 months in service, the HVTS cladding showed no signs of defects, and the plant was able to confidently continue operations without the constant threat of corrosion-related failures. It was a true testament to the power of this innovative technology.

The Advantages of Weld Overlay Cladding

What makes weld overlay cladding such a game-changer in the world of corrosion protection? Let’s dive into the key benefits:

-

Targeted Corrosion Protection: Unlike blanket solutions like refractory linings, weld overlay cladding allows you to selectively target the areas most vulnerable to corrosion, ensuring maximum protection where it’s needed most.

-

Enhanced Reliability: By creating a physical barrier between the base metal and the corrosive environment, weld overlay cladding significantly reduces the risk of leaks, failures, and unexpected downtime – a critical consideration for mission-critical equipment.

-

Cost-Effectiveness: Replacing entire components or structures can be prohibitively expensive, but weld overlay cladding offers a more budget-friendly solution. It allows you to extend the useful life of existing equipment without the need for costly replacements.

-

Tailored Metallurgy: The choice of alloy used in the weld overlay cladding can be precisely tailored to the specific corrosion challenges faced in your application. This flexibility ensures an optimal, long-lasting solution.

-

Environmental Benefits: By avoiding the need for wholesale equipment replacement, weld overlay cladding also reduces the environmental impact associated with manufacturing and installing new components. It’s a sustainable approach that aligns with the growing emphasis on eco-friendly practices in our industry.

The Evolution of Weld Overlay Cladding Techniques

While the basic concept of weld overlay cladding has been around for decades, the technology has continued to evolve, with new techniques and advancements that are pushing the boundaries of what’s possible.

One of the most promising developments is the use of high-velocity thermal spray (HVTS) cladding, which I had the opportunity to work with on that boiler project I mentioned earlier. This process allows for the application of a thin, highly dense and homogeneous layer of corrosion-resistant material without the need for extensive dilution with the base metal.

The benefits of HVTS cladding are numerous. By minimizing the heat input and avoiding the creation of a heat-affected zone, it eliminates the risk of residual stresses and distortion in the underlying structure. And the finely structured, low-permeability coating delivers exceptional protection against corrosion, outperforming traditional weld overlay techniques.

I’ve also been impressed by the advancements in automated and mechanized welding solutions for weld overlay cladding. These innovative systems allow for superior quality control, higher production rates, and a level of precision that’s simply not achievable with manual welding.

One of the fabrication shops I collaborate with has invested heavily in these cutting-edge technologies, and the results have been nothing short of remarkable. The ability to apply consistent, uniform cladding layers with minimal dilution has been a game-changer, allowing us to deliver long-lasting corrosion protection that meets the most stringent industry standards.

The Importance of Surface Preparation and Process Control

Of course, as with any welding or fabrication process, the success of weld overlay cladding is heavily dependent on the quality of the surface preparation and the rigorous control of the application process.

I’ve seen too many cases where corners were cut or critical steps were overlooked, leading to premature failures and costly rework. That’s why I always emphasize the importance of meticulous surface cleaning, proper joint fit-up, and the strict adherence to welding procedures and quality control protocols.

It’s a bit like baking a cake – if you don’t have the right ingredients and follow the recipe to a tee, the end result is likely to be a disappointment. The same principle applies to weld overlay cladding. Every detail, from the selection of the filler material to the monitoring of interpass temperatures, can make the difference between a durable, long-lasting solution and a costly failure.

The Power of Collaboration and On-Site Expertise

As an experienced welder and fabricator, I’ve learned that the most successful corrosion protection projects are the ones where the entire team, from the project managers to the technicians in the field, are working in lockstep. It’s about leveraging the collective expertise and coordinating the efforts to ensure seamless execution.

That’s why I’m such a strong advocate for on-site collaboration with our clients and their vendors. By having a dedicated team of specialists working directly on the project, we’re able to address challenges in real-time, optimize processes, and ensure that the end result meets or exceeds the customer’s expectations.

I’ve seen this approach pay dividends time and time again. Whether it’s developing custom welding procedures, troubleshooting equipment issues, or fine-tuning the application techniques, the ability to react quickly and make informed decisions on the spot is invaluable.

And let’s not forget the importance of ongoing maintenance and monitoring. Weld overlay cladding is an incredibly robust solution, but it’s not immune to the ravages of time and wear. That’s why I always emphasize the need for regular inspections, preventive maintenance, and proactive adjustments to ensure the longevity of the corrosion protection.

The Future of Weld Overlay Cladding

As I look to the future, I can’t help but feel excited about the continued evolution of weld overlay cladding technologies. The advancements we’ve seen in recent years, from high-velocity thermal spray to automated welding systems, are just the tip of the iceberg.

I can envision a future where corrosion-resistant coatings are applied with unparalleled precision, creating seamless, impervious barriers that can withstand the harshest of environments. And with the growing emphasis on sustainability and environmental stewardship, I believe that weld overlay cladding will play an increasingly vital role in extending the lifespan of critical industrial equipment, reducing the need for costly and energy-intensive replacements.

At the end of the day, my passion for welding and metal fabrication is all about solving problems and creating innovative solutions. And when it comes to the challenge of corrosion, I firmly believe that weld overlay cladding is a game-changer – a technology that can help us push the boundaries of what’s possible in heavy industry.

So, if you’re facing corrosion issues in your own operations, I encourage you to explore the power of weld overlay cladding. It may just be the key to unlocking a new era of reliability, efficiency, and sustainable metalworking. And if you ever need a hand, you know where to find me – I’ll be right here, ready to lend my expertise and share the latest insights from the world of The Weld Fab.