As an experienced welder and metal fabricator, I’ve had the privilege of witnessing the remarkable evolution of welding technology over the years. Among the most captivating advancements has been the rise of laser welding, particularly in the realm of aluminum alloys. Today, I’m excited to share my insights and personal experiences with this innovative technique that is transforming the way we approach metal fabrication.

The Allure of Laser Welding

When it comes to welding aluminum alloys, precision and finesse are paramount. Traditional welding methods have long struggled to deliver the level of control and quality required for these intricate materials. However, the advent of laser welding has opened up a whole new world of possibilities.

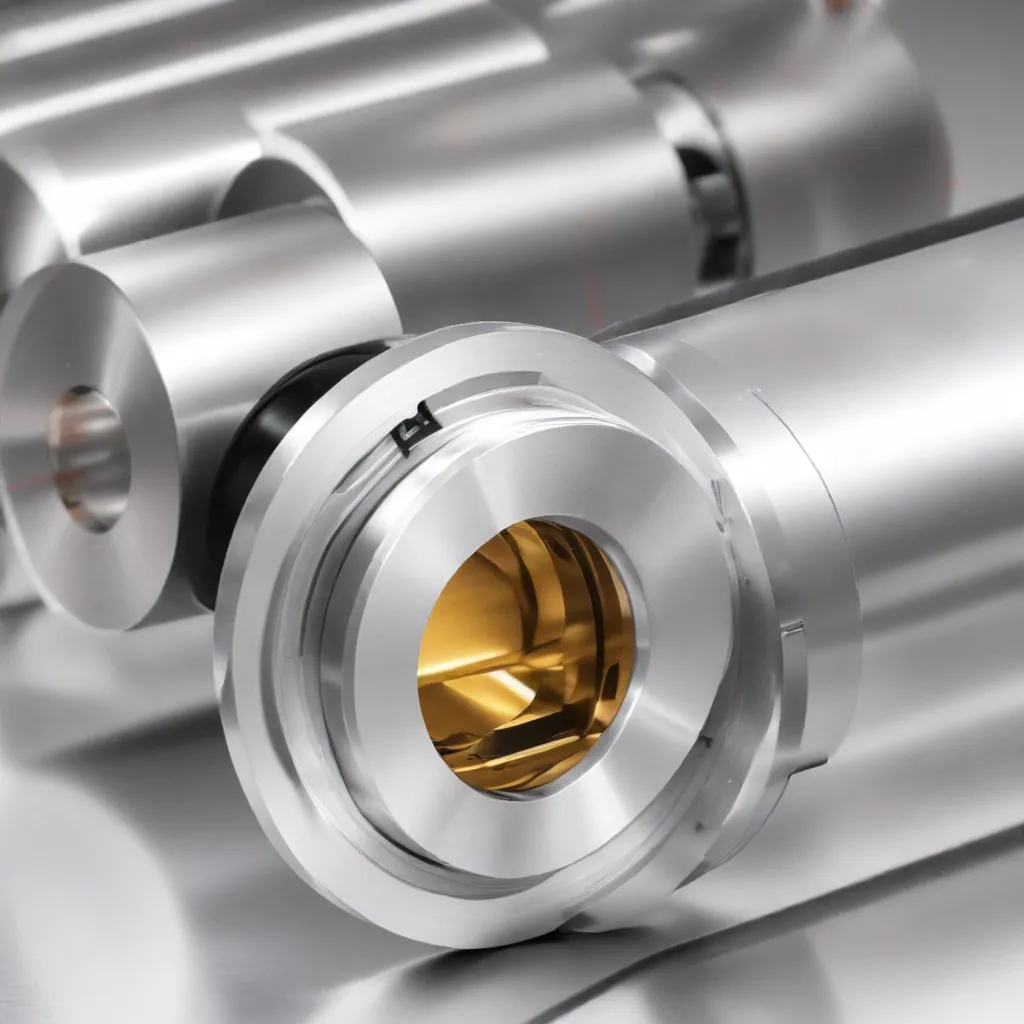

The beauty of laser welding lies in its ability to harness the power of concentrated light to melt and fuse metals with unparalleled accuracy. Unlike conventional techniques that rely on bulky torches or arcs, the laser beam’s intense energy is focused on a microscopic spot, allowing for seamless joins with minimal distortion or heat-affected zones.

As a welder, I’ve been awestruck by the sheer speed and efficiency of laser welding. Gone are the days of painstakingly aligning parts and carefully maintaining temperature control. With laser welding, the process is streamlined, allowing us to churn out high-quality welds at a fraction of the time and effort.

But the true magic of laser welding lies in its capacity to handle the unique properties of aluminum alloys. These materials, with their low melting points and high thermal conductivity, have long been a thorn in the side of welders. However, the precision of laser technology enables us to navigate these challenges with ease, producing strong, uniform, and aesthetically pleasing joints time and time again.

Mastering the Intricacies of Aluminum Welding

Aluminum alloys are indeed a fascinating and sometimes finicky set of materials to work with. Each blend presents its own unique characteristics, and as fabricators, we must be attuned to the nuances of these differences.

Take, for instance, the aluminum-copper alloy. This formidable blend boasts exceptional strength, making it a staple in the aerospace industry for components like wings and fuselages. However, its tendency to resist corrosion can pose a challenge during the welding process. Careful temperature control and shielding gas selection become critical to ensuring a successful joint.

On the other hand, the aluminum-magnesium alloy is a marvel of marine engineering, prized for its corrosion-resistant properties in saltwater environments. But its susceptibility to cracking under high heat loads requires us to adopt a delicate touch, meticulously managing the heat input and cooling rates.

And let’s not forget the aluminum-silicon alloy, a workhorse in the automotive world. Its low melting point and excellent castability make it a dream to work with, but its relative inflexibility means we must approach the welding process with a deft hand to maintain the material’s integrity.

Navigating these material nuances is where the true artistry of welding shines. It’s not just about mastering the technical aspects of the craft, but also developing an intuitive understanding of how each alloy will respond to the intensity of a laser beam. It’s a dance of precision, where even the slightest misstep can mean the difference between a flawless weld and a costly failure.

The Laser Welding Toolkit

As with any craft, the tools of the trade play a crucial role in the success of our endeavors. When it comes to laser welding aluminum alloys, the choice of equipment can make all the difference.

In the world of laser welding, we have a few primary contenders vying for our attention: fiber lasers, CO2 lasers, and solid-state lasers like the Nd:YAG. Each of these technologies brings its own unique strengths and weaknesses to the table, and as seasoned fabricators, we must carefully weigh the pros and cons to determine the right fit for our specific needs.

Fiber lasers, for instance, have emerged as the frontrunners in terms of efficiency and beam quality. Their crisp, focused beams allow for precise control, making them the go-to choice for intricate, high-speed applications. However, the initial investment in these systems can be a significant hurdle for smaller operations.

CO2 lasers, on the other hand, offer a more budget-friendly alternative, with a broader skill set that extends beyond just metalworking. While their efficiency may take a hit when it comes to aluminum, their versatility and comparatively lower upfront costs make them an appealing option for those with diverse fabrication requirements.

And then there are the solid-state Nd:YAG lasers, which offer the flexibility of fiber optic delivery, allowing for easy integration with automated systems and robotic workcells. Their ability to provide a range of wavelengths opens up new possibilities in terms of material compatibility, but concerns over beam quality and the risk of overheating can’t be ignored.

As a seasoned fabricator, I’ve had the opportunity to work with all of these laser technologies, and I can attest to the importance of carefully evaluating the unique needs of each project and aligning them with the appropriate equipment. It’s a delicate balancing act, but one that pays dividends in the form of consistently outstanding welds.

The Laser Welding Process: A Symphony of Precision

Welding aluminum alloys with lasers is a symphony of precision, where every step must be meticulously orchestrated to achieve the desired outcome. As with any art form, it’s not enough to simply possess the tools; we must also develop a deep understanding of the underlying principles that govern the process.

Let’s start with the all-important surface preparation. Just as a painter must meticulously prime their canvas, we as welders must ensure that the aluminum surfaces are pristine, free from any contaminants that could compromise the integrity of the weld. A simple misstep here can mean the difference between a flawless joint and a disastrous failure.

Once the stage is set, the real magic begins. The laser beam, a concentrated burst of energy, zeroes in on the aluminum, rapidly heating the material to its melting point. But it’s not just about brute force; the true skill lies in precisely controlling the power, speed, and focus of that beam to produce the perfect weld profile.

And let’s not forget the role of the shielding gas – a crucial element in protecting the molten metal from atmospheric contamination. The right blend of argon or helium can mean the difference between a clean, strong weld and one riddled with porosity or oxidation.

But the symphony doesn’t end there. As the laser makes its pass, the molten pool of aluminum follows in its wake, quickly solidifying into a solid, uniform joint. And it’s not just about the weld itself; the surrounding heat-affected zone must also be carefully managed to ensure the structural integrity of the entire assembly.

It’s a delicate dance, to be sure, but one that I’ve had the privilege of mastering over the years. With each successful weld, I take immense pride in the precision and finesse we’ve been able to achieve, knowing that the end result will stand the test of time and exceed the highest industry standards.

Laser Welding in Action: Showcasing its Versatility

As a welder and fabricator, I’ve had the opportunity to witness the transformative power of laser welding across a wide range of industries. From the sleek, lightweight aircraft of the aerospace sector to the high-performance vehicles in the automotive world, this technology has become an indispensable tool in the pursuit of innovation and excellence.

In the aerospace industry, for instance, laser welding has revolutionized the way we approach the construction of critical components like wings and fuselages. The precision and control afforded by this technique have enabled us to create seamless, stronger-than-ever joints that can withstand the rigors of high-speed flight without sacrificing weight or aerodynamic efficiency.

Similarly, in the automotive realm, laser welding has become a crucial ally in the quest for improved fuel efficiency and reduced emissions. By seamlessly joining intricate parts and panels, we’re able to shave off precious pounds from the vehicle’s overall weight, all while maintaining the structural integrity required to keep drivers and passengers safe.

But the applications of laser welding extend far beyond the realms of aviation and automotive manufacturing. In the electronics sector, this technology has proven to be a game-changer, allowing us to create durable, thermally efficient casings and components for the ever-shrinking gadgets that power our digital lives.

And let’s not forget the packaging industry, where laser welding has become a hygienic and reliable solution for sealing aluminum cans and containers, ensuring the longevity and freshness of the products within.

The list goes on, and as I reflect on the diverse applications of this remarkable technology, I can’t help but marvel at the way it continues to push the boundaries of what’s possible in the world of metal fabrication. Time and time again, laser welding has proven itself to be a versatile, precision-driven tool that is more than up to the task of meeting the ever-evolving demands of modern industry.

Ensuring Safety and Quality: The Foundation of Laser Welding

As with any advanced manufacturing process, safety and quality assurance are of the utmost importance when it comes to laser welding. After all, the sheer power and precision of this technology demands a level of respect and diligence that cannot be overlooked.

First and foremost, the personal protective equipment (PPE) worn by our welding team is of the utmost importance. From specialized safety glasses that shield our eyes from the intense light to heat-resistant gloves and coveralls, we leave no stone unturned in ensuring that our crew is safeguarded from the potential hazards of this process.

But it’s not just about protecting our personnel; it’s also about maintaining the integrity of the work itself. Regular equipment checks and calibrations are a crucial part of our laser welding routine, ensuring that every weld is executed with the highest level of accuracy and consistency.

And let’s not forget the importance of a well-ventilated workspace. The fumes and particulates generated during the welding process can pose a significant health risk, so we’ve invested in state-of-the-art exhaust systems and air filtration units to keep our environment clean and safe.

But the real secret to our success lies in the skills and expertise of our welding team. These aren’t just technicians; they’re true artists, with a deep understanding of the science and physics that underpin the laser welding process. They know how to read the subtle nuances of the molten metal, adjusting the parameters in real-time to ensure a flawless result.

It’s this commitment to safety and quality that sets us apart in the industry. Our clients know that when they entrust us with their projects, they’re not just getting top-notch welding services – they’re getting the peace of mind that comes from working with a team of true professionals who take pride in every single weld.

The Future of Laser Welding: Automation and Sustainability

As I look towards the horizon, I can’t help but feel a sense of excitement about the future of laser welding. This technology, once the realm of niche industries, is poised to become an integral part of the manufacturing landscape, driven by the relentless pursuit of innovation and efficiency.

One of the most intriguing developments on the horizon is the integration of advanced automation and robotics into the laser welding process. Imagine a world where precision-guided robotic arms seamlessly execute complex weld patterns, with real-time monitoring and adjustment to ensure flawless results. This level of automation not only boosts productivity but also enhances consistency, reducing the risk of human error and ensuring the highest standards of quality.

But the future of laser welding isn’t just about speed and efficiency; it’s also about sustainability. As the world becomes increasingly conscious of its environmental impact, we’re seeing a growing demand for manufacturing processes that are not only cutting-edge but also eco-friendly.

Laser welding, with its focused energy delivery and minimal heat-affected zones, is poised to become a frontrunner in this green revolution. By reducing energy consumption and material waste, this technology is helping to pave the way for a more sustainable future, where the pursuit of progress and the preservation of our planet can coexist in perfect harmony.

And as a welder and fabricator, I can’t help but feel a sense of pride in being a part of this transformation. Every time I see a sleek, high-performance aircraft take to the skies or a fuel-efficient vehicle hit the open road, I know that the work we do here at The Weld Fab has played a small but vital role in making those dreams a reality.

Embracing the Future with Laser Welding

As I reflect on my experiences in the world of metal fabrication, I can’t help but feel a profound sense of gratitude for the remarkable advancements we’ve witnessed in welding technology, particularly the rise of laser welding.

This innovative technique has not only transformed the way we approach the challenges of working with aluminum alloys, but it has also opened up a world of possibilities in terms of speed, precision, and sustainability. And as a seasoned fabricator, I can attest to the immense pride and satisfaction that comes from mastering this craft and delivering consistently outstanding results.

Whether it’s the sleek, lightweight components of an aircraft, the high-performance parts of a cutting-edge vehicle, or the durable casings of our beloved electronics, laser welding has become an indispensable tool in the pursuit of innovation and excellence. And as we look towards the future, I can’t help but feel excited about the ways in which this technology will continue to push the boundaries of what’s possible.

So, if you’re a fellow welder or fabricator, I encourage you to embrace the power of laser welding and all that it has to offer. Immerse yourself in the intricacies of this craft, hone your skills, and take pride in the precision and finesse you’re able to achieve. And for those outside the industry, I hope this article has shed some light on the remarkable world of laser welding and the ways in which it is shaping the future of manufacturing.

After all, at the heart of it all, we are a community of innovators, problem-solvers, and creators – united by our passion for the art of metalworking and our unwavering commitment to pushing the boundaries of what’s possible. And with the power of laser welding at our fingertips, the possibilities are truly endless.

So, let’s raise a proverbial torch to the future of this remarkable technology and the countless ways in which it will continue to transform our world. The Weld Fab is ready to embrace the challenge, and we can’t wait to see what the future holds.