Mastering the Laser Welding Advantage

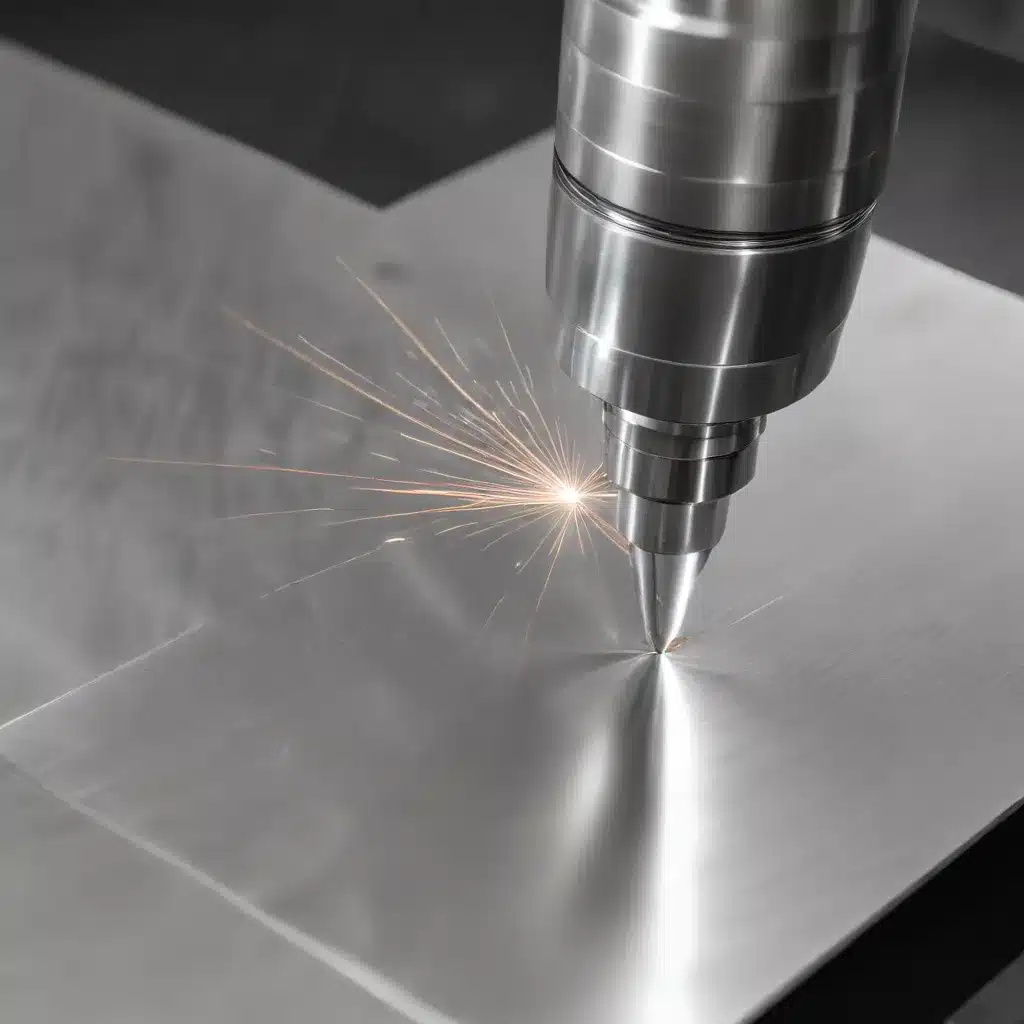

As an experienced welder and metal fabricator, I’ve had the privilege of witnessing the transformative power of laser welding technology firsthand. Over the years, I’ve seen how this revolutionary technique has reshaped our industry, enabling us to achieve unprecedented levels of precision, speed, and efficiency.

Laser welding has become a game-changer, allowing us to tackle projects that were once considered impossible. Its ability to join a wide range of materials, from thin and lightweight to complex and intricate, has opened up new avenues for innovation and creativity. Whether we’re working on aerospace components, medical devices, or high-performance automotive parts, the precision and control offered by laser welding have become indispensable.

One of the standout features of laser welding is its remarkable speed. In my experience, we’ve been able to complete projects up to 50% faster than with traditional welding methods, without sacrificing the quality of the welds. This boost in productivity has been a game-changer, allowing us to meet tighter deadlines and stay ahead of the competition.

The Precision Edge

But speed is not the only advantage of laser welding. The precision it offers is truly unparalleled. I’ve seen how laser welding can consistently achieve tolerances as tight as 0.005 mm, a level of accuracy that was once considered nearly impossible. This level of precision is crucial in industries where even the slightest deviation can lead to catastrophic failures, such as in aerospace and medical applications.

The ability to minimize heat input and distortion is another key benefit of laser welding. When working on delicate components or thin-walled structures, traditional welding methods often lead to warping and deformation. However, with laser welding, we’ve been able to minimize the heat-affected zone and maintain the integrity of the materials, reducing the need for extensive post-weld finishing and rework.

Versatility and Adaptability

One of the aspects I’ve truly come to appreciate about laser welding is its versatility. This technology allows us to join a wide range of materials, including dissimilar metals, with remarkable ease. This capability has opened up new avenues for design and manufacturing, enabling us to create innovative products that cater to the ever-evolving demands of our industries.

Furthermore, the adaptability of laser welding systems has been a game-changer. With the ability to fine-tune parameters such as power, beam diameter, and welding speed, we can tailor the process to the specific needs of each project. This level of control has allowed us to tackle a diverse range of welding challenges, from delicate medical devices to heavy-duty automotive components.

Fiber Lasers vs. Handheld Lasers

As I’ve delved deeper into the world of laser welding, I’ve come to appreciate the distinct advantages of both fiber laser welding machines and handheld laser welding systems. Fiber laser welders are renowned for their exceptional speed and consistency, making them the go-to choice for high-volume production environments. Their ability to weld at speeds exceeding 5 meters per minute, while maintaining remarkable accuracy, is truly impressive.

On the other hand, handheld laser welding systems offer a level of flexibility and adaptability that is unmatched. Their portability allows us to tackle welding tasks in hard-to-reach areas or on complex geometries, making them invaluable for repair work, intricate art installations, and custom fabrication projects. While their seam quality may not always match the precision of fiber lasers, their ease of use and versatility make them an essential tool in our workshop.

Mastering the Laser Welding Process

Achieving consistently high-quality laser welds requires a deep understanding of the intricate relationship between laser parameters and material properties. Over the years, I’ve learned that it’s not enough to simply operate the machine; mastering the art of laser welding involves a meticulous approach to every aspect of the process.

Carefully adjusting the laser power, beam diameter, and welding speed to match the specific material and thickness being joined is crucial. For example, when working with highly reflective metals like aluminum or copper, I’ve found that using a pulsed laser mode can significantly minimize the risk of reflection and damage to the equipment.

Similarly, understanding the unique characteristics of each material is essential. Metals like stainless steel, with their lower thermal conductivity, require a different approach compared to materials like titanium, which have higher thermal conductivity. By fine-tuning the laser settings and welding techniques, I’m able to achieve consistent, high-quality welds that meet the stringent specifications of our industries.

Safety and Maintenance: Cornerstones of Excellence

Ensuring the safety and longevity of our laser welding equipment is of paramount importance. I’ve implemented a comprehensive safety protocol that includes the use of specialized personal protective equipment, such as welding helmets with auto-darkening lenses and respiratory protection, to safeguard myself and my team from potential hazards.

Additionally, I’ve developed a rigorous maintenance routine to keep our laser welding machines operating at their peak performance. Regular inspections of critical components, such as the lens and coolant systems, have helped extend the lifespan of our equipment and maintain the exceptional quality of our welds.

By staying vigilant and proactive in our maintenance practices, we’ve been able to minimize downtime and maintain a consistent level of productivity, ensuring that our customers receive the best possible service and products.

Laser Welding in Action: Transforming Industries

The impact of laser welding technology has been truly transformative across various industries. In the automotive sector, for instance, the precision and speed of laser welding have revolutionized the way we manufacture car bodies and components. The tight, almost invisible joints created by laser welding not only enhance the structural integrity and safety of vehicles but also contribute to their striking aesthetic appeal.

Moreover, the ability to accommodate advanced high-strength steels and lightweight alloys has enabled us to optimize the balance between weight and strength, leading to improved fuel efficiency and sustainability without compromising on safety standards.

The medical industry has also greatly benefited from the advancements in laser welding. The micron-level accuracy and minimal heat input have made it possible to produce complex, intricate medical devices that meet the strictest safety and quality requirements. From pacemakers and surgical tools to dental implants, laser welding has transformed the way we manufacture these critical life-saving and life-enhancing products.

In the aerospace and defense sectors, the role of laser welding has been equally vital. The precision and strength of laser-welded joints have contributed to the enhanced durability and performance of aircraft fuselages, turbine engines, and specialized military equipment. By reducing material waste and production time, laser welding has become an indispensable technology in these industries, where every micron and millisecond count.

Embracing the Future of Welding

As I reflect on my journey in the metal fabrication industry, I can’t help but feel excited about the future of welding. The advancements in laser welding technology are truly remarkable, and I believe they will continue to shape the way we approach our work.

With the integration of CNC and 3D printing capabilities, the possibilities for laser welding are endless. The ability to automate complex welding patterns and tackle intricate three-dimensional geometries has opened up new avenues for innovation and creativity. I can’t wait to see how these technologies will continue to push the boundaries of what’s possible in our field.

But beyond the technical advancements, I’m most excited about the potential for laser welding to transform the way we approach our craft. By harnessing the power of precision, speed, and adaptability, we can elevate the quality and efficiency of our work, delivering exceptional results to our customers while ensuring the safety and longevity of our equipment.

As we move forward, I’m committed to staying at the forefront of this rapidly evolving industry. By continually refining my skills, exploring new techniques, and embracing the latest technologies, I’m confident that I can maintain my position as a trusted expert in the world of welding and metal fabrication.

If you’re interested in learning more about the capabilities of laser welding and how it can benefit your business, I encourage you to visit The Weld Fab website. There, you’ll find a wealth of information and resources to help you navigate the exciting world of precision welding and metal fabrication.