Embracing the Power of Laser Welding in Fabrication

As an experienced welder and metal fabricator, I’ve had the privilege of witnessing the transformative power of laser welding technology firsthand. Over the years, I’ve seen this revolutionary technique reshape the way we approach welding tasks, enabling us to achieve results that were once considered impossible.

One of the areas where laser welding has truly excelled is in the fabrication of nickel-based superalloys. These high-performance materials, prized for their exceptional strength, heat resistance, and corrosion-resistance, have become indispensable in industries like aerospace, energy, and defense. However, their unique properties also present significant challenges when it comes to traditional welding methods.

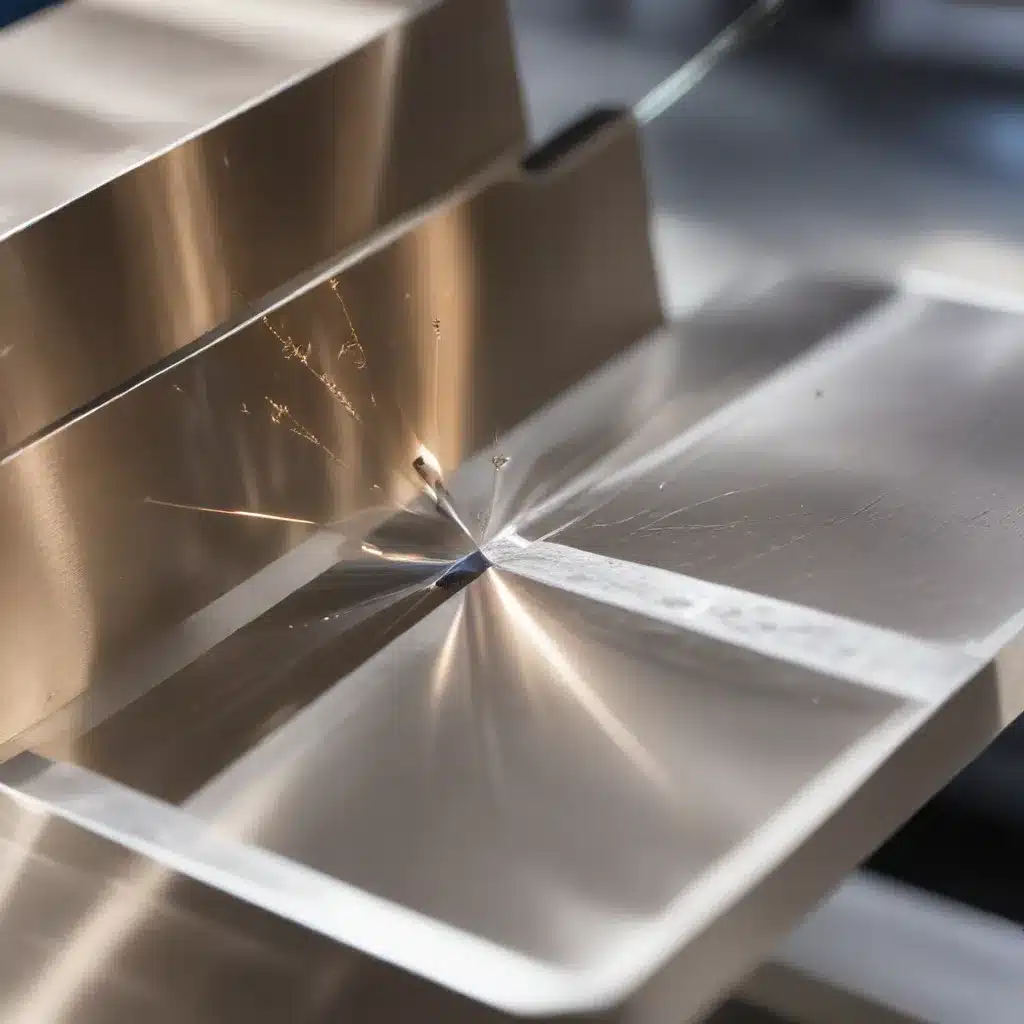

That’s where laser welding steps in, unlocking a new realm of possibilities. With its unparalleled precision, speed, and efficiency, this technology has become a game-changer in the fabrication of nickel-based superalloys. By precisely targeting the weld area and minimizing the heat input, laser welding allows us to maintain the integrity of these critical materials, ensuring that the final products meet the most stringent specifications.

In my experience, the benefits of laser welding in nickel-based superalloy fabrication are truly remarkable. Not only does it consistently deliver high-quality, distortion-free welds, but it also significantly reduces the time and resources required for each project. This efficiency translates into cost savings, quicker turnaround times, and an overall improvement in the production process.

Precision and Efficiency: The Hallmarks of Laser Welding

One of the standout features of laser welding that makes it so well-suited for nickel-based superalloys is its unrivaled precision. The laser’s ability to focus its energy onto a tiny, targeted area allows for exceptional control over the weld parameters, ensuring that the heat input is carefully tailored to the specific material and thickness requirements.

This level of precision is crucial when working with high-performance alloys like those found in aerospace and defense applications. Even the slightest deviation in the weld can compromise the structural integrity and performance of the final product. With laser welding, I’ve been able to consistently achieve tolerances of within 0.005 mm, a feat that would be nearly impossible to replicate using traditional welding techniques.

Moreover, the speed of laser welding is simply unmatched. In a recent project involving the fabrication of aircraft components, I was able to complete the welding process in half the time it would have taken using conventional MIG or TIG welding methods. This increased efficiency not only enhances productivity but also reduces the risk of defects, as the shorter welding time minimizes the potential for distortion or other weld-related issues.

Preserving Material Integrity: The Key Advantage of Laser Welding

One of the most significant benefits of laser welding when working with nickel-based superalloys is its ability to minimize heat input and, consequently, preserve the integrity of the materials being joined. These alloys are renowned for their exceptional mechanical properties, which can be easily compromised by the excessive heat associated with traditional welding techniques.

In my experience, the localized and controlled heat input of laser welding has been instrumental in maintaining the strength, hardness, and overall structural integrity of nickel-based superalloys. By focusing the heat precisely where it’s needed, I’ve been able to minimize the heat-affected zones (HAZs) and prevent the degradation of the materials’ critical properties.

This advantage is especially crucial in applications where even the slightest compromise in material performance can have catastrophic consequences, such as in the aerospace and defense sectors. Maintaining the integrity of these high-performance alloys is not just a matter of quality; it’s a matter of safety and reliability.

Expanding the Boundaries of Fabrication with Laser Welding

As I reflect on my journey in the fabrication industry, I’ve witnessed firsthand how laser welding has expanded the boundaries of what’s possible. This innovative technology has enabled us to tackle design challenges that were once considered insurmountable, unlocking new avenues for innovation and creativity.

One of the most striking examples of this is the ability to join dissimilar materials using laser welding. Traditionally, welding different alloys together has been a significant challenge, often leading to compromised mechanical properties or even failures. However, the precision and control offered by laser welding have allowed us to overcome these barriers, opening up new possibilities for product design and material selection.

In a recent project, I was tasked with fabricating a complex assembly that required the seamless integration of titanium and nickel-based superalloy components. By carefully adjusting the laser parameters and optimizing the welding process, I was able to create a robust and reliable joint that met the stringent performance requirements of the application. This level of material versatility is a testament to the transformative power of laser welding technology.

Embracing the Future of Fabrication with Laser Welding

As I look to the future, I’m convinced that laser welding will continue to shape the trajectory of the fabrication industry. The advantages it offers in terms of precision, efficiency, and material integrity are simply too significant to ignore. In fact, I foresee laser welding becoming the preferred choice for a wide range of applications, from aerospace and defense to medical and automotive manufacturing.

The ability to consistently produce high-quality welds, reduce material waste, and enhance production speed will be crucial in meeting the ever-evolving demands of modern industries. Moreover, the versatility of laser welding, with its capability to handle a diverse range of materials and joint configurations, will allow fabricators like myself to push the boundaries of design and innovation.

Mastering the Art of Laser Welding: A Continual Journey

Harnessing the full potential of laser welding technology is an ongoing process that requires a deep understanding of both the equipment and the materials being worked on. Over the years, I’ve dedicated countless hours to experimenting, testing, and refining my techniques to ensure that I can consistently deliver the exceptional results that my clients have come to expect.

One of the key aspects of mastering laser welding is the ability to precisely control the laser parameters, such as power, speed, and beam diameter, to suit the specific requirements of the project. This knowledge comes from a combination of theoretical understanding and practical experience, where I’ve meticulously documented the optimal settings for different materials and thicknesses.

Moreover, I’ve learned that the surrounding environment and pre-weld preparation play a crucial role in the success of laser welding. Maintaining a clean, well-controlled work area, using the appropriate shielding gases, and ensuring the surface condition of the materials are all critical factors that I carefully consider before even firing up the laser.

Overcoming the Challenges of Reflective Metals

Working with highly reflective materials like aluminum, copper, and stainless steel has been one of the most significant challenges I’ve faced in my laser welding journey. The tendency of these metals to reflect the laser beam can pose serious risks to the equipment and the welder, requiring a deep understanding of mitigation strategies.

Through extensive experimentation and research, I’ve developed a range of techniques to address this challenge. Adjusting the laser to operate in pulsed mode, using a higher power setting to overcome the reflectivity, and employing specialized shielding gases are just a few of the approaches I’ve mastered. By staying vigilant and continuously adapting my methods, I’ve been able to successfully tackle even the most reflective of materials, ensuring the safety of both the equipment and myself.

Maintaining Flawless Welds: The Importance of Meticulous Technique

Producing consistently flawless welds is not just a matter of technical expertise; it also requires a meticulous approach to the welding process itself. I’ve learned that even the slightest deviation in technique can have a significant impact on the quality and integrity of the final weld.

In my experience, factors such as maintaining a steady hand, moving the laser at a constant pace, and carefully monitoring the temperature of the weld zone are all crucial elements of achieving superior results. By applying these principles with unwavering precision, I’ve been able to create welds that not only meet the stringent standards of my clients but also exceed their expectations.

Additionally, I’ve recognized the importance of comprehensive safety protocols in ensuring the well-being of both myself and the fabrication team. From wearing the appropriate protective gear to maintaining a meticulously organized and fire-resistant work environment, I’ve made safety an integral part of my laser welding practice.

Elevating Productivity and Efficiency through Laser Welding

One of the most remarkable aspects of laser welding technology is its ability to enhance productivity and efficiency in the fabrication process. By leveraging the speed and precision of this advanced technique, I’ve been able to significantly reduce the time and resources required to complete projects, all while maintaining the highest levels of quality.

In a recent automotive parts assembly project, I was able to complete the welding work in half the time it would have taken using traditional MIG welding methods. This improvement in speed not only translated to cost savings but also allowed us to meet tighter deadlines and stay ahead of the competition.

Moreover, the reduced heat input and minimal distortion associated with laser welding have dramatically decreased the need for post-weld finishing and rework. This has streamlined the overall fabrication process, enabling me to allocate more resources towards innovation and expanding the capabilities of my workshop.

Embracing the Future: Laser Welding in Modern Industries

As I look to the future, I’m excited to witness the continued integration of laser welding technology across a wide range of industries. From aerospace and defense to medical device manufacturing and beyond, the precision, efficiency, and material integrity offered by this advanced technique are simply unmatched.

In the automotive sector, for example, laser welding has become a game-changer, revolutionizing the way critical components are fabricated. The ability to create seamless, high-strength joints on complex assemblies has not only enhanced the safety and performance of modern vehicles but also opened the door to new design possibilities.

Similarly, in the medical field, the use of laser welding has transformed the way intricate devices, such as surgical tools and implants, are produced. By maintaining the structural integrity of biocompatible materials and minimizing the heat-affected zones, laser welding has enabled the creation of more reliable and long-lasting medical solutions.

As these industries continue to push the boundaries of what’s possible, I’m confident that the role of laser welding will only become more prominent. By staying at the forefront of this technology and constantly refining my skills, I aim to be a trusted partner in the fabrication of the next generation of high-performance products.

Conclusion: Embracing the Future with Laser Welding

As I reflect on my journey in the fabrication industry, I can’t help but be amazed by the transformative power of laser welding technology. From its unparalleled precision and efficiency to its ability to preserve the integrity of even the most challenging materials, this innovation has truly revolutionized the way we approach welding tasks.

In my experience, the integration of laser welding has not only enhanced the quality and consistency of the final products but also streamlined the overall fabrication process, leading to significant cost savings and improved productivity. As I continue to push the boundaries of what’s possible with this technology, I’m excited to see how it will shape the future of industries across the globe.

Whether you’re a fellow fabricator, an industry leader, or simply someone curious about the advancements in welding technology, I encourage you to explore the world of laser welding. The possibilities are endless, and the potential to revolutionize the way we approach fabrication is truly inspiring.

To learn more about The Weld Fab and our commitment to delivering high-quality, innovative welding and fabrication solutions, please visit our website at theweldfab.com. Together, let’s unlock the future of fabrication.