The Evolution of Welding Technology

As an experienced welder and metal fabricator, I’ve witnessed firsthand the remarkable advancements in welding technology over the years. While traditional welding methods like TIG and MIG have served us well, the emergence of laser welding has truly revolutionized the way we approach fabrication.

Let me take you on a journey through my own experiences with this cutting-edge technology. When I first encountered laser welding, I was instantly captivated by its unparalleled precision and efficiency. Gone were the days of painstaking manual adjustments and inconsistent results – laser welding offered a level of control and accuracy that seemed almost superhuman.

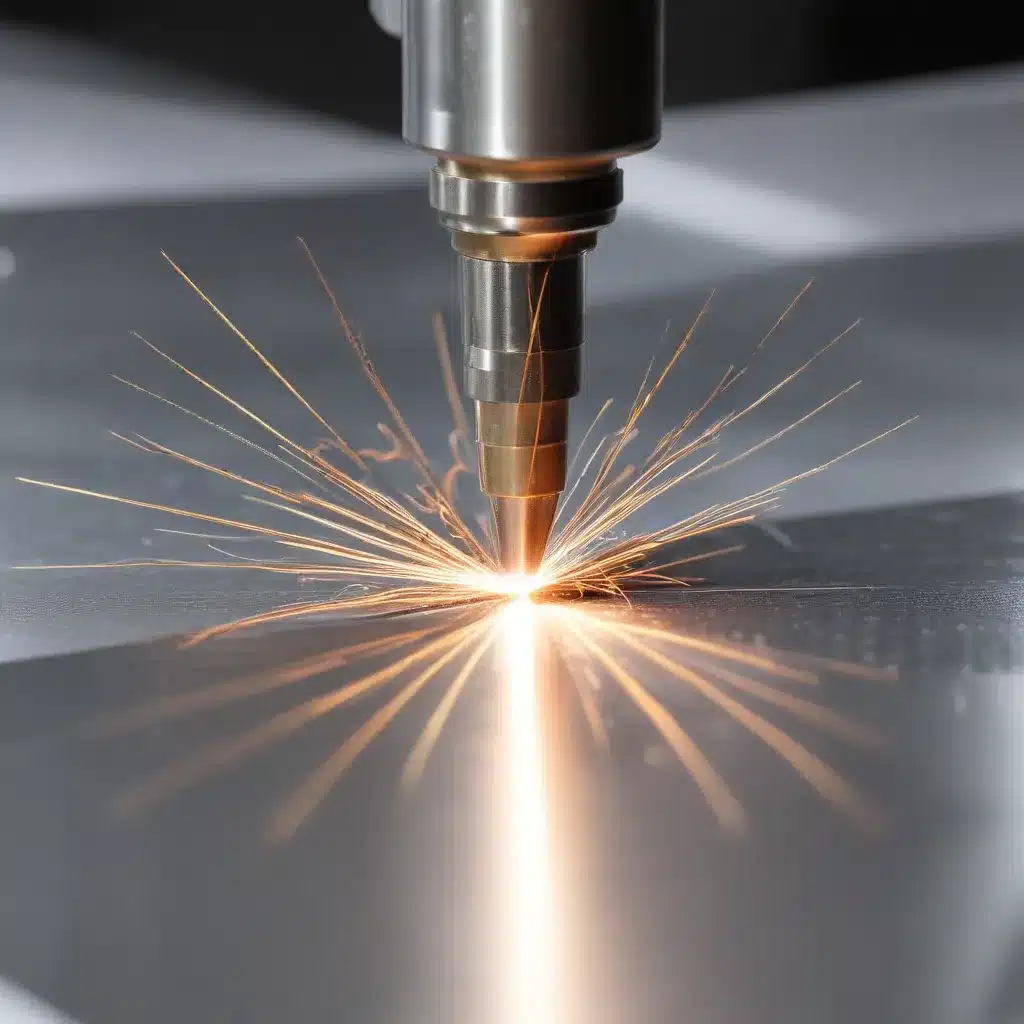

One of the key advantages I’ve observed is the laser’s ability to focus a concentrated beam of energy onto a precise area, allowing for seamless, high-quality welds with minimal distortion. This precision has been a game-changer, particularly in industries where even the slightest deviation can have catastrophic consequences, such as aerospace and medical device manufacturing.

Precision, Speed, and Efficiency

What really sets laser welding apart, in my opinion, is its sheer speed and efficiency. In a recent automotive parts assembly project, I was able to complete the work in just half the time it would have taken using traditional MIG welding methods. The results were equally, if not more, impressive – the laser-welded joints were strong, uniform, and required minimal post-processing.

This speed and precision have proven invaluable in industries where time is of the essence. In the medical field, for instance, laser welding has allowed us to manufacture complex, intricate devices with unparalleled accuracy, enabling healthcare providers to access critical equipment more quickly. The reduction in manual labor and rework has also led to significant cost savings, making these life-saving technologies more accessible.

But it’s not just about speed and efficiency – laser welding’s ability to minimize heat distortion has been a revelation. When working on thin-walled components for precision instruments, I’ve witnessed how traditional welding methods can cause warping and damage, rendering the parts useless. With laser welding, however, I’ve been able to maintain tight tolerances and preserve the integrity of the materials, reducing the need for extensive post-weld corrections.

Versatility and Adaptability

One of the aspects of laser welding that continues to impress me is its versatility. This technology has the remarkable ability to join a wide range of materials, from dissimilar metals to advanced composites, unlocking new design possibilities for fabricators like myself.

Take the aerospace industry, for example. The growing preference for lightweight, high-performance materials has led to an increased demand for welding solutions that can handle these complex, intricate components. Laser welding has proven to be the perfect fit, allowing us to seamlessly join titanium alloys and carbon fiber reinforced polymers without compromising the structural integrity or functionality of the final product.

Mastering the Art of Laser Welding

Of course, mastering the art of laser welding requires a deep understanding of the equipment and materials involved. Over the years, I’ve learned that it’s not just about setting the right parameters – it’s about fine-tuning the delicate interplay between laser settings and the unique properties of each material.

For instance, when working with reflective metals like aluminum or copper, I’ve had to develop specialized techniques to minimize the risk of damaging the laser source. By using pulsed laser modes and carefully controlling the beam focus, I’ve been able to achieve consistent, high-quality welds without compromising the integrity of the equipment.

Similarly, understanding the importance of heat input and its effects on various materials has been crucial in my journey as a laser welding expert. By meticulously monitoring parameters like power, speed, and beam diameter, I’ve been able to optimize the welding process for different thicknesses and alloys, ensuring that each weld is tailored to the specific application.

Embracing the Future of Welding

As I reflect on my experiences with laser welding, I can’t help but feel a sense of excitement for the future of our industry. This technology has not only transformed the way we approach fabrication but has also opened up new avenues for innovation and creativity.

I envision a future where laser welding becomes the industry standard, revolutionizing the way we manufacture products across a wide range of sectors. Whether it’s creating intricate medical devices, building lightweight and durable aircraft components, or crafting high-performance automotive parts, this technology will continue to push the boundaries of what’s possible.

At the heart of this vision is a deep appreciation for the art of precision joining. As a welder and fabricator, I take immense pride in the work I do, and laser welding has allowed me to take that pride to new heights. With every seamless, high-quality weld, I’m not just creating a product – I’m pushing the limits of what can be achieved through the power of technology and the skill of the human hand.

Conclusion: Embracing the Future of Welding

As I look back on my journey with laser welding, I can’t help but feel a deep sense of gratitude for the advancements that have transformed our industry. This technology has not only elevated the quality and efficiency of our work but has also opened up new possibilities for innovation and creativity.

Whether it’s building the next generation of advanced medical devices, crafting lightweight and durable aerospace components, or manufacturing high-performance automotive parts, laser welding has become an indispensable tool in our fabrication arsenal. And as we continue to push the boundaries of what’s possible, I can’t wait to see what the future holds.

So, if you’re a fellow welder or fabricator, I encourage you to embrace the power of laser welding. Dive deep into the intricacies of this technology, experiment with different techniques and materials, and unlock the true potential of precision joining. Together, we can redefine the landscape of our industry and leave an indelible mark on the world.

Welcome to the future of welding, my friends. It’s time to wield the power of the laser and create something truly extraordinary.