As an experienced welder and metal fabricator, I’ve had the privilege of witnessing the remarkable advancements in 3D printing technology over the years. One area that has truly captivated my attention is the frontiers of metal 3D printing, specifically the realm of Laser Powder Bed Fusion (LPBF). This innovative technique has revolutionized the way we approach metal fabrication, and I’m excited to share my insights with you.

The Evolution of LPBF: From Prototype to Production

In the past, 3D printing has predominantly been viewed as a tool for prototyping and small-scale production. However, the landscape is rapidly changing, and LPBF is at the forefront of this transformation. I’ve seen firsthand how this technology is transitioning from a mere prototyping solution to a viable option for direct production.

One of the key players driving this evolution is Eplus3D, a leading manufacturer of metal additive manufacturing equipment. Their commitment to exploring the boundaries of LPBF technology has been truly remarkable. With their unwavering focus on revolutionizing the industry, they’ve consistently pushed the limits of what’s possible in metal 3D printing.

The EP-M2050: Redefining Productivity and Efficiency

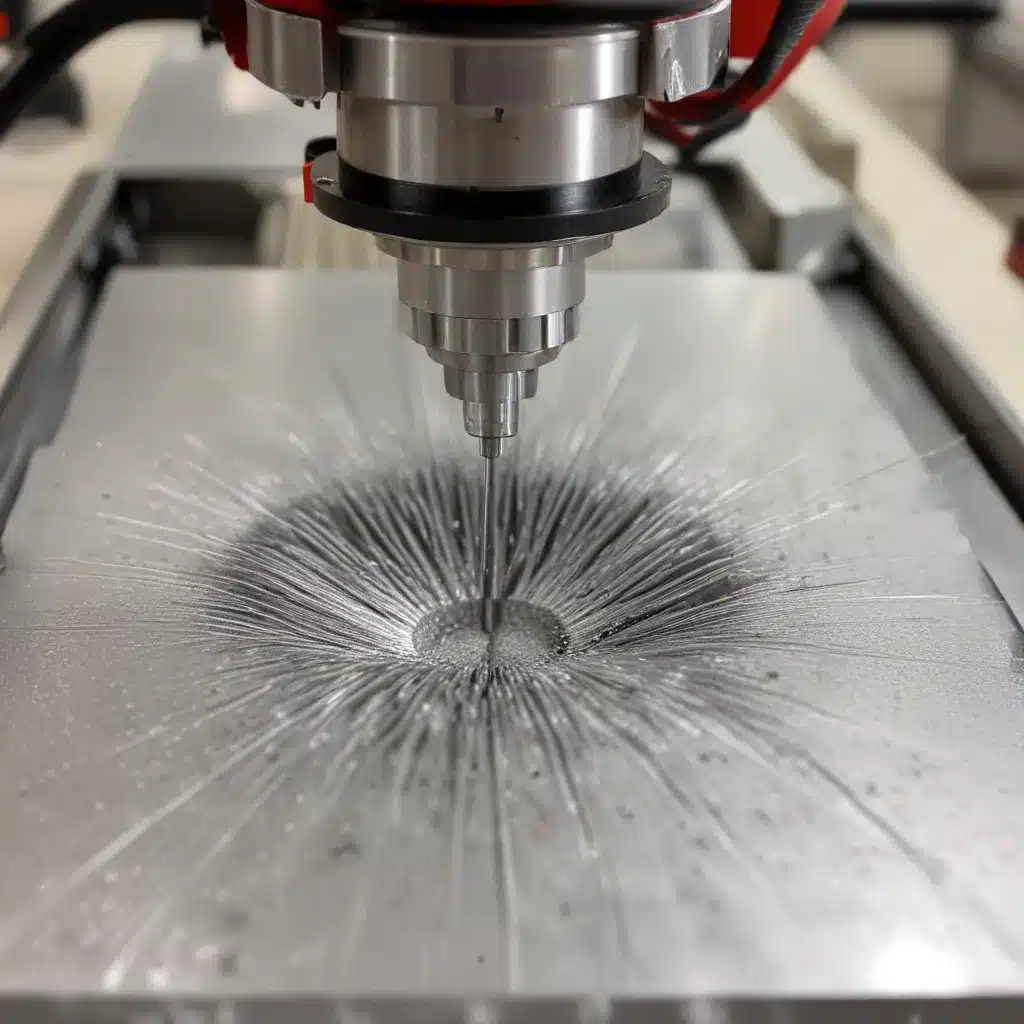

The latest addition to Eplus3D’s lineup, the EP-M2050, is a true game-changer in the world of metal additive manufacturing. This large-format, multi-laser metal AM system is a testament to the company’s dedication to innovation. Boasting a unique six-by-six laser matrix equipped with 36 galvanometers, the EP-M2050 ensures seamless operation of all its lasers in perfect synchrony.

But that’s not all – the system can be optionally upgraded to accommodate an impressive 64 lasers, arranged in an eight-by-eight laser matrix with 64 galvanometers. This exceptional capability not only revolutionizes productivity but also elevates the level of versatility and efficiency that the EP-M2050 brings to the table.

Pushing the Boundaries of Scale and Precision

One of the standout features of the EP-M2050 is its impressive build volume of 2050 x 2050 x 1100 mm, with an optional extension to 2000 mm in height. This remarkable size range breaks through the constraints that have traditionally limited metal 3D printing, allowing for the production of large-scale, high-precision components.

As a welder and fabricator, I understand the importance of scale and precision in our industry. The ability to manufacture parts of such significant dimensions while maintaining remarkable consistency is a game-changer. It opens up a world of possibilities for industries that demand the utmost quality and precision, such as aerospace, energy, and other high-performance sectors.

Flexibility and Material Versatility

The EP-M2050 offers exceptional flexibility in terms of material processing. It can be equipped with either 500 W or 700 W fiber lasers, empowering it to work with a diverse range of materials, including titanium alloy, aluminum alloy, stainless steel, and tool steel.

This material versatility is a crucial aspect for metal fabricators like myself. Being able to process a wide variety of metals allows us to tackle a broader range of projects and cater to the diverse needs of our clients. Whether it’s producing high-strength aerospace components or intricate industrial parts, the EP-M2050 provides the necessary flexibility to handle the job.

Precision Layer Control for High-Quality Outcomes

Another impressive feature of the EP-M2050 is its layer thickness range of 20-120 μm. This level of precision in layer control is essential for achieving exceptional part quality and dimensional accuracy. As a welder, I know the importance of paying close attention to even the smallest details, and the EP-M2050 delivers on that front.

With its ability to manufacture large-scale, high-precision components, this system is truly a game-changer for industries that require the utmost attention to detail. Whether it’s aircraft parts, medical implants, or complex industrial equipment, the EP-M2050 ensures that the end products meet the most stringent quality standards.

Optimizing Safety and Efficiency

Safety and efficiency are paramount in any fabrication or welding operation, and the EP-M2050 addresses these concerns with its integrated features. The system can be connected to a closed-loop sieving tower, ensuring the highest level of user safety, reduced downtime, and minimal material waste.

As someone who has worked in the industry for years, I can attest to the importance of having the right equipment and processes in place to maintain a safe and efficient work environment. The EP-M2050’s seamless integration with the sieving tower is a testament to Eplus3D’s commitment to providing comprehensive solutions that prioritize the well-being of the operator and the overall productivity of the operation.

Collaborative Innovations: Powering the Future

The development of the EP-M2050 is a testament to Eplus3D’s deep understanding of the industry’s needs and their dedication to collaborating with their customers. By listening to the requirements of various sectors, they have been able to design a system that truly revolutionizes the way metal parts are produced today.

As a welder and fabricator, I’m excited to see how this technology will continue to evolve and shape the future of our industry. The EP-M2050’s ability to push the boundaries of scale, precision, and material versatility opens up a world of possibilities. I can’t wait to see how it will empower businesses like mine to tackle even more ambitious projects and deliver exceptional results to our clients.

Embracing the Potential of LPBF

The landscape of metal fabrication is rapidly evolving, and LPBF technology like the EP-M2050 is at the forefront of this transformation. As an experienced welder, I’ve seen firsthand how this innovative approach to metal 3D printing is redefining the way we think about production.

Gone are the days when 3D printing was confined to the realm of prototyping. With the EP-M2050’s remarkable capabilities, we now have the opportunity to seamlessly transition from prototype to production, harnessing the power of large-scale, high-precision metal fabrication.

Elevating the Fabrication Experience

At the heart of my passion for welding and metal fabrication is the pursuit of perfection. I take immense pride in the quality of my work, and the EP-M2050 aligns perfectly with this ethos. Its unparalleled precision, material versatility, and production efficiency empower us to elevate the fabrication experience, delivering results that exceed our clients’ expectations.

As I reflect on my journey in the industry, I can’t help but feel excited about the future. With the EP-M2050 and other transformative technologies, we are poised to push the boundaries of what’s possible in metal fabrication. The opportunities ahead are truly limitless, and I can’t wait to see how we continue to innovate and redefine the landscape of our craft.

Forging Ahead: The Weld Fab and the Future of Metal Fabrication

At The Weld Fab, we are committed to staying at the forefront of the industry, embracing the latest advancements in welding and metal fabrication. The EP-M2050 is a testament to the kind of game-changing technology that we strive to incorporate into our operations, empowering us to deliver exceptional results to our clients.

As we forge ahead, I am confident that the future of metal fabrication holds untold possibilities. With the continued innovation and collaboration between industry leaders like Eplus3D and dedicated professionals like myself, the sky is the limit. I’m excited to be a part of this journey, and I look forward to the day when I can harness the full potential of the EP-M2050 to create truly remarkable, precision-engineered metal components.