The Seamless Marriage of Strength and Lightness

As an experienced welder and metal fabricator, I’ve had the privilege of working with a wide range of materials, but none quite as captivating as the world of aluminum alloys. These lightweight wonders have revolutionized industries, from aviation to automotive, and I’m honored to share my insights on the cutting-edge technique that has made their union possible: friction stir welding.

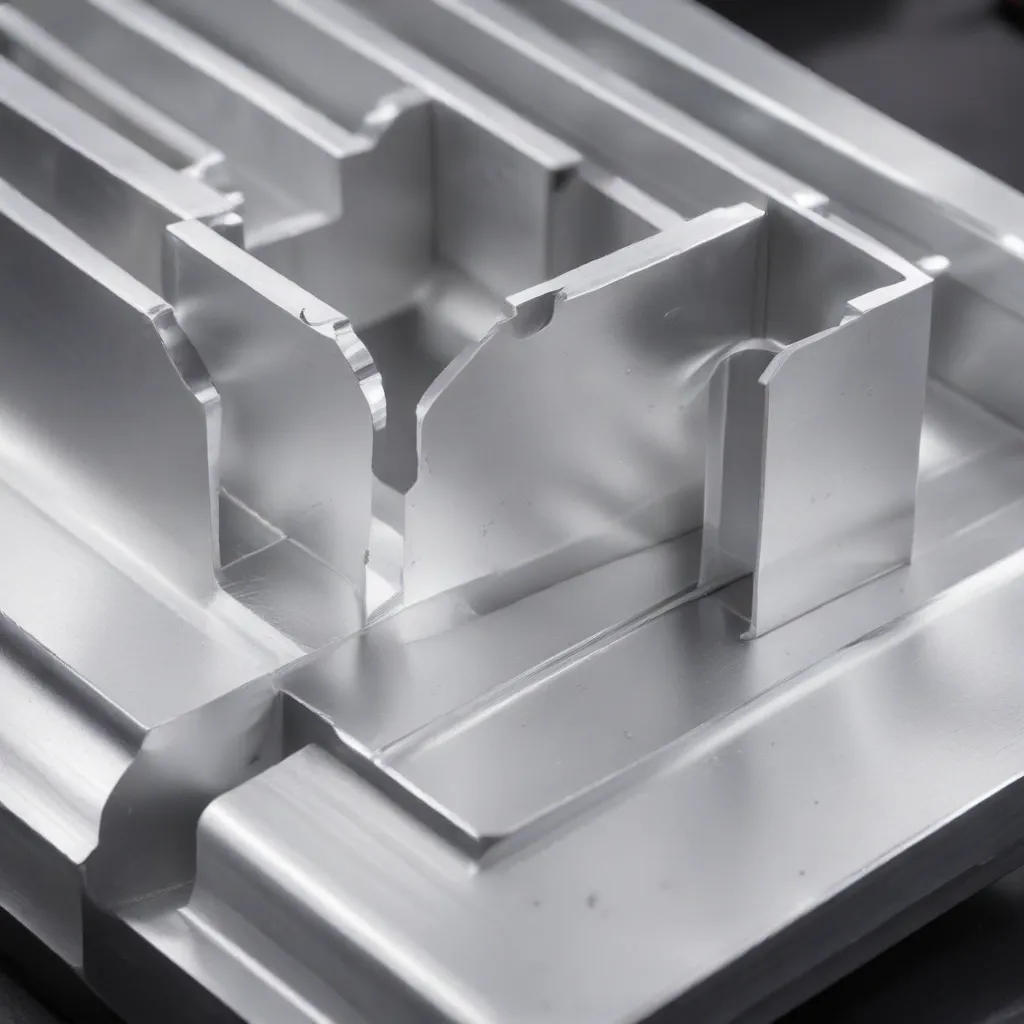

Aluminum alloys have long been a source of fascination for me, with their remarkable strength-to-weight ratio and unparalleled corrosion resistance. Yet, traditional welding methods have often struggled to tame these alloys, leaving behind distortions, warping, and subpar structural integrity. That is, until the ingenious invention of friction stir welding (FSW) came along and forever changed the game.

The Power of Friction Stir Welding

At its core, FSW is a solid-state joining process that utilizes frictional heat to bond materials together without ever reaching their melting point. This ingenious approach not only eliminates the issues inherent in fusion welding but also unlocks a world of possibilities for the aerospace and transportation industries.

One of the most remarkable aspects of FSW is its ability to weld high-strength aluminum alloys that were once considered virtually unweldable. These alloys, renowned for their lightweight and superior performance, have long been a holy grail for engineers seeking to push the boundaries of design and efficiency. With FSW, the once-elusive dream of seamlessly joining these materials has become a reality.

Transforming the Aerospace Industry

The impact of FSW on the aerospace industry cannot be overstated. As the demand for lightweight, high-performance aircraft soars, manufacturers have turned to this revolutionary technique to revolutionize their production processes.

By utilizing FSW to join airframe structures, such as wing skins and fuselage components, manufacturers have been able to achieve remarkable weight savings. In fact, one leading aircraft manufacturer estimated that the substitution of rivets with FSW can result in a weight reduction of up to 1 kilogram per meter. This seemingly small improvement can have a cascading effect, allowing planes to fly farther, reduce fuel consumption, and ultimately, lower operating costs.

But the benefits of FSW go far beyond just weight savings. The process also boasts improved structural rigidity, enhanced fatigue performance, and a remarkable reduction in the number of fasteners and components required. Imagine an aircraft fuselage or wing that is seamlessly joined, without the need for thousands of rivets and the associated rework and inspection. This is the reality that FSW has brought to the aerospace industry.

Pushing the Boundaries of Efficiency

One of the most impressive aspects of FSW is its ability to drastically improve the efficiency of the manufacturing process. By eliminating the need for time-consuming riveting and the associated rework, FSW has enabled a staggering 10-fold reduction in assembly times for certain aircraft components.

Consider the example of a U.S.-based jet manufacturer that partnered with PAR Systems to design a custom FSW gantry system capable of welding an entire aircraft frame in just 8 hours. This remarkable feat was made possible by the continuous, automated nature of the FSW process, which creates accurate and repeatable welds with virtually no need for rework.

The implications of this efficiency boost are far-reaching. By reducing labor hours and streamlining production, manufacturers can offer more affordable aircraft to their customers, making air travel accessible to a broader audience. It’s a win-win scenario that showcases the transformative power of this innovative welding technique.

Unlocking the Potential of Cryogenic Tanks

But the benefits of FSW extend beyond just the airframe – they also hold immense potential for the construction of cryogenic fuel tanks, a crucial component in the push for a more sustainable aviation industry.

Traditionally, the use of rivets and gaskets in cryogenic tank construction has been a significant source of concern, with the potential for leaks and structural integrity issues. However, FSW’s ability to create a gas-tight, seamless seal without the need for additional fasteners has opened up new possibilities.

Collaborative research between Boeing and NASA has demonstrated the remarkable performance of FSW-joined cryogenic tanks, with improved corrosion resistance, reduced residual stresses, and superior stability. This breakthrough paves the way for the safe and reliable use of hydrogen fuel in commercial aircraft, a crucial step towards a more eco-friendly future for the aviation industry.

Embracing the Endless Possibilities

As I reflect on the remarkable advancements in aluminum alloy joining, I can’t help but feel a sense of excitement and pride. The marriage of precision metal fabrication and cutting-edge welding techniques, such as FSW, has truly revolutionized the way we approach design and manufacturing challenges.

But the story doesn’t end here. The potential of FSW extends far beyond the aerospace industry, with applications ranging from the construction of bullet trains and passenger rail cars to the fabrication of hermetically sealed containers for the life sciences and data storage sectors.

In the world of commercial transportation, FSW’s ability to join dissimilar materials and minimize the number of fasteners has unlocked new possibilities for weight reduction and improved reliability. Imagine a future where trains and trailers are built with the same level of structural integrity and corrosion resistance as our aircraft – a future made possible by the innovations in friction stir welding.

Redefining the Fabrication Landscape

As a welder and metal fabricator, I’ve had the privilege of witnessing the evolution of our industry firsthand. Gone are the days of relying on traditional fusion welding and its inherent limitations. In its place, we now have the power of FSW, a technique that has not only transformed the way we approach joining tasks but has also redefined the very boundaries of what’s possible.

At The Weld Fab, we take great pride in our ability to leverage the latest advancements in welding and fabrication technology to deliver unparalleled results for our clients. Whether it’s the construction of a lightweight, corrosion-resistant aircraft component or the fabrication of a hermetically sealed container for the life sciences industry, we are committed to pushing the boundaries of what’s achievable.

Embracing the Future with Precision and Passion

As I look ahead, I can’t help but feel a sense of excitement for the future of our industry. The continued advancements in materials, welding techniques, and automation are paving the way for a new era of precision, efficiency, and innovation.

At The Weld Fab, we are proud to be at the forefront of this transformation, leveraging our expertise and the power of cutting-edge technologies like friction stir welding to deliver unparalleled results for our clients. Whether you’re an aerospace engineer, a transportation manufacturer, or a innovator in the life sciences industry, we are here to partner with you and help you unlock the full potential of your metal fabrication projects.

So, let’s embrace the future together, with a steadfast commitment to precision, a passion for excellence, and a shared vision of what’s possible when we push the boundaries of what’s achievable. The world of welding and fabrication is evolving, and The Weld Fab is ready to lead the way.