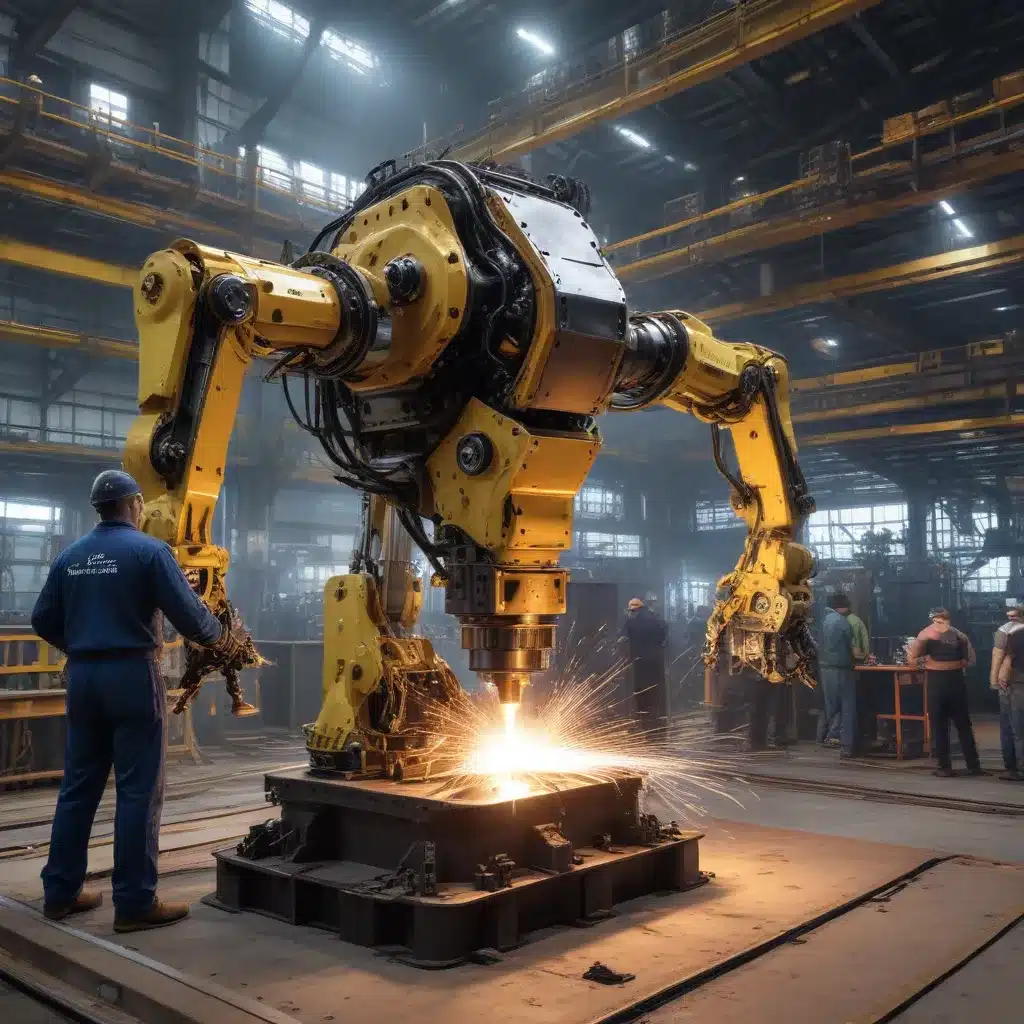

As an experienced welder and metal fabricator, I’ve had the privilege of witnessing firsthand the incredible advancements in robotic welding technology, particularly within the shipbuilding industry. Gone are the days of relying solely on manual welding techniques to tackle the intricate challenges of constructing massive marine structures. Today, robotic welding has emerged as a game-changer, revolutionizing the way we approach the fabrication of complex vessels and offshore platforms.

In this article, I’ll share my personal insights and experiences as I delve into the world of robotic welding for shipbuilding. From the precision and efficiency it brings to the challenges it helps overcome, I’ll explore how this cutting-edge technology is transforming the very fabric of our industry.

Precision and Consistency: The Hallmarks of Robotic Welding

When it comes to constructing large-scale marine structures, precision and consistency are paramount. Every weld, every seam, every joint must meet the highest standards of quality and durability. This is where robotic welding shines, offering a level of precision that can be difficult to achieve with manual techniques.

I’ve had the privilege of working with some of the latest robotic welding systems, and I can attest to the remarkable level of control and repeatability they provide. These advanced systems use sophisticated sensors and algorithms to precisely monitor and adjust the welding parameters, ensuring that each weld is executed with remarkable accuracy. Gone are the days of relying on the human eye and steady hand to maintain the perfect angle, speed, and heat input – the robots handle it all with unparalleled precision.

One of the key benefits I’ve experienced with robotic welding is the consistency it brings to the fabrication process. When working on large-scale projects, maintaining consistent weld quality across hundreds or even thousands of joints can be a daunting task. With robotic welding, however, I’ve seen a remarkable reduction in weld defects and inconsistencies. The robots’ ability to follow pre-programmed patterns and maintain precise control over the welding parameters ensures that every weld is executed with the same level of quality, time and time again.

Increased Productivity and Efficiency

In the world of shipbuilding, where time is of the essence and deadlines are relentless, the ability to increase productivity and efficiency is crucial. Robotic welding has proven to be a game-changer in this regard, offering unparalleled speed and throughput compared to manual welding techniques.

One of the most impressive aspects of robotic welding is its sheer capacity for work. These machines are capable of operating 24/7 with minimal downtime, allowing for a level of output that would be simply exhausting for a human welder. I’ve witnessed robotic welding cells churning out weld after weld, with seamless coordination and no fatigue or loss of focus. This sustained productivity translates directly to faster project completion times and higher returns on investment.

Moreover, the precision and repeatability of robotic welding systems help to reduce the need for rework and quality checks. By minimizing defects and ensuring consistent weld quality, these automated systems can dramatically improve the overall efficiency of the fabrication process. I’ve seen projects where the implementation of robotic welding has shaved weeks, if not months, off the construction timeline, all while maintaining the highest standards of workmanship.

Tackling Complex Geometries and Difficult-to-Reach Areas

One of the most impressive capabilities of robotic welding systems in the shipbuilding industry is their ability to handle complex geometries and access difficult-to-reach areas. The intricate designs of modern vessels, with their intricate curves, tight spaces, and hard-to-access joints, can pose a significant challenge for manual welding techniques.

However, the flexibility and dexterity of robotic welding systems allow them to navigate these complex structures with ease. I’ve witnessed robotic welding arms contort and maneuver into tight spaces, seamlessly executing welds in areas that would be virtually impossible for a human welder to access. The ability to program these robots to follow precise paths and trajectories enables them to tackle the most intricate and challenging fabrication tasks with remarkable precision.

Moreover, the adaptability of robotic welding systems means that they can be easily reconfigured to handle a wide range of parts and components. Whether it’s the complex hull of a massive cargo ship or the delicate framework of a luxury yacht, these automated systems can be quickly adapted to suit the unique requirements of each project. This level of versatility is a true game-changer, allowing fabricators to tackle a diverse range of marine structures with a single, highly capable robotic welding solution.

Enhancing Safety and Reducing Worker Fatigue

In the world of heavy industry, where welding and fabrication are often hazardous and physically demanding tasks, the importance of worker safety and well-being cannot be overstated. Robotic welding systems have proven to be invaluable in this regard, offering a safer and more ergonomic alternative to manual welding.

One of the primary benefits of robotic welding is the elimination of the need for workers to be in close proximity to the welding arc and the intense heat and fumes it produces. By isolating the welding process within a secure, automated cell, these systems dramatically reduce the exposure of workers to the hazards associated with manual welding. This not only enhances overall safety but also helps to prevent long-term health issues that can arise from prolonged exposure to welding fumes and UV radiation.

Moreover, robotic welding systems can significantly reduce the physical strain and fatigue experienced by workers. Manual welding can be incredibly taxing, requiring sustained physical effort and precise control over the welding torch. In contrast, robotic welding systems handle the majority of the physical work, allowing workers to focus on tasks that are less physically demanding, such as part preparation, inspection, and quality control.

As someone who has spent countless hours hunched over a welding table, I can attest to the toll it can take on the body. The ability to offload the physical strain of welding to a robotic system has been a game-changer, allowing me and my colleagues to maintain our productivity and focus while minimizing the risk of injury and fatigue.

Embracing the Future of Shipbuilding with Robotic Welding

As I reflect on the remarkable advancements in robotic welding technology, I can’t help but feel a sense of excitement for the future of the shipbuilding industry. The integration of these cutting-edge systems has the potential to transform the way we approach the fabrication of complex marine structures, ushering in a new era of precision, efficiency, and safety.

The ability to automate the welding process, while maintaining the highest standards of quality and consistency, is a true testament to the ingenuity and innovation driving our industry forward. By leveraging the power of robotic welding, we can not only streamline the fabrication process but also unlock new possibilities in the design and construction of vessels that were once thought to be beyond our reach.

As I continue to explore the capabilities of these advanced robotic welding systems, I’m constantly in awe of the ways in which they can push the boundaries of what’s possible. From tackling intricate geometries to enhancing worker safety, these technologies are redefining the very fabric of our industry.

If you’re a fellow welder or metal fabricator, I encourage you to explore the world of robotic welding and witness firsthand the incredible impact it can have on your own work. Whether you’re involved in shipbuilding, offshore construction, or any other heavy industry, these automated systems offer a glimpse into the future of precision metalworking. And who knows, perhaps your own experiences and insights will inspire the next generation of innovation within The Weld Fab.