As an experienced welder and metal fabricator, I’ve had the privilege of working on some truly remarkable projects over the years. From constructing the intricate components that form a seaworthy vessel to harnessing the power of automation to streamline complex welding processes, the shipbuilding industry has always been a fascinating and dynamic realm for me.

Shipbuilding: The Beating Heart of Global Trade and Defense

The shipbuilding industry is the lifeblood of global transportation and defense. Whether we’re talking about massive commercial vessels or specialized military submarines, these floating giants require an unparalleled level of precision and expertise to bring to life. As a welder, I’ve been in awe of the sheer complexity and scale of these projects, where every weld, every pipe, and every structural element is critical to the vessel’s integrity and performance.

One of the things that has always struck me about the shipbuilding industry is the wealth of experience and hands-on know-how that goes into each and every project. From the skilled welders and pipefitters to the carpenters and riggers, the collective expertise of the workforce is truly awe-inspiring. These are the individuals who use their years of hard-earned knowledge to shape the intricate components that define a seaworthy vessel.

However, as I’m sure you’re aware, the shipbuilding industry is facing a significant challenge – the retirement of experienced workers. As these seasoned professionals step away from the job, the shipyards are left with a growing void that is difficult to fill. The Korea Offshore & Shipbuilding Association forecasts that the industry will face a shortage of around 14,000 workers by the end of 2023, with an additional 45,000 workers needed to deliver on secured orders.

Bridging the Knowledge Gap with Robotic Welding

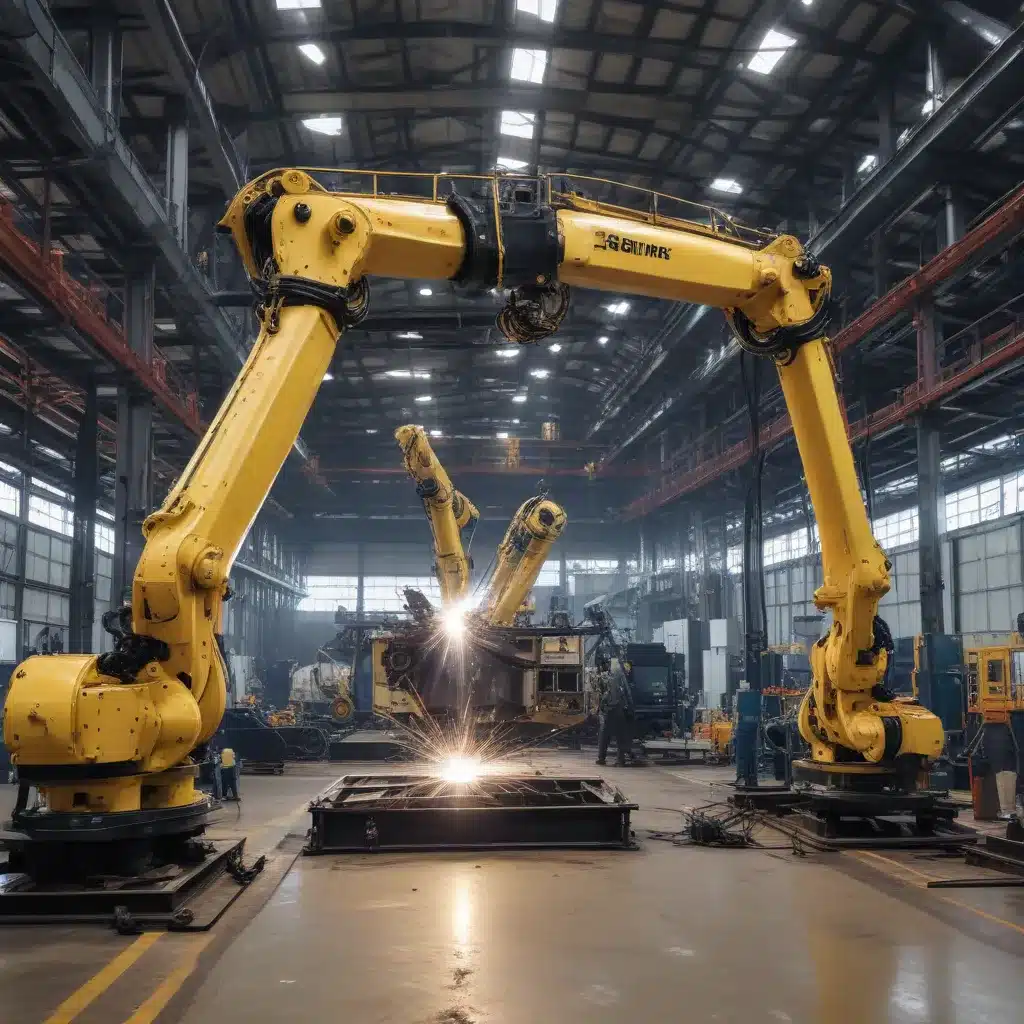

In this dynamic landscape, where skilled labor is in high demand, the shipbuilding industry has had to look for innovative solutions to maintain its competitive edge. And one of the most promising avenues is the integration of robotic welding technology.

Now, I know what you might be thinking – won’t robots just replace human welders and fabricators? But the reality is quite the opposite. Robotic welding is not about displacing the skilled workforce; it’s about empowering them to focus on the high-value, high-skill tasks that truly make a difference.

By automating certain welding processes, shipyards can free up their experienced welders to tackle the more complex and intricate fabrication challenges that require their expertise. This not only helps to bridge the knowledge gap left by retiring workers but also allows the skilled workforce to truly shine, applying their decades of know-how to the most critical aspects of the project.

One of the key benefits of robotic welding in the shipbuilding industry is its ability to improve workflow efficiency and increase productivity. According to the source, implementing robots in the shipyard can shorten the welding time by two-thirds and save approximately $94 million annually. That’s a staggering statistic that speaks to the transformative power of this technology.

Take, for example, the case of one of the world’s three biggest shipyards, which has implemented the use of a 16-kilogram robotic arm, affectionately known as the “caddy,” to weld steel parts while constructing LNG commercial carriers. This robotic arm allows the shipyard to execute large welding steel structures in confined spaces, a task that would be incredibly challenging and time-consuming for a human welder.

Ensuring Quality and Safety with Robotic Welding

But it’s not just about speed and efficiency – robotic welding also brings significant improvements to quality and safety. By standardizing the welding process and eliminating human variability, robotic systems can deliver consistently high-quality welds that meet the stringent requirements of the shipbuilding industry.

I’ve seen firsthand how robotic welding can enhance quality control and inspection processes. A major naval shipyard, for instance, is leveraging Dassault Systèmes’ DELMIA Augmented Experience solution to streamline their quality inspection procedures. As a result, parts that used to take 45 minutes to inspect now take only 10 minutes, which corresponds to a remarkable over 70% improvement in efficiency on the shop floor.

Moreover, the integration of virtual commissioning and simulation capabilities allows shipyards to ensure the smooth deployment of new robotic welding programs, minimizing disruptions and potential issues on the shop floor. This risk-free exposure to simulated tasks helps to optimize training procedures and processes, ultimately enhancing both safety and productivity.

Embracing the Future of Shipbuilding with Model-Based Manufacturing

One of the most exciting aspects of the robotic welding revolution in the shipbuilding industry is its connection to the broader trend of model-based manufacturing. By leveraging advanced software solutions, shipyards are able to capture and transfer critical know-how more efficiently, empowering the next generation of workers to step up and contribute to these complex projects.

The source highlights the use of 3D work instructions as a clear example of model-based manufacturing, which results in faster and more efficient manufacturing execution. This technology allows for seamless knowledge transfer, ensuring that the hard-won expertise of experienced welders and fabricators can be effectively passed down to the newcomers joining the industry.

But the benefits of model-based manufacturing extend far beyond just knowledge transfer. By integrating manufacturing execution systems (MES) like Dassault Systèmes’ DELMIA Apriso, shipyards can now monitor and control their production processes with unprecedented precision. This means they can access real-time, data-driven key performance indicators (KPIs) to optimize their workflows, identify bottlenecks, and make informed decisions that drive continuous improvement.

Embracing a Lean and Agile Approach to Shipbuilding

As shipyards continue to navigate the challenges of the modern industry, the adoption of lean management principles has become a critical component of their success. By streamlining their production plans and implementing integrated quality control, material synchronization, and maintenance procedures, these facilities are able to deliver on the ever-increasing demands for on-time, on-budget, and high-quality vessel construction.

The source cites the “Build For Sea” industry solution from Dassault Systèmes as an example of how shipyards are leveraging these lean manufacturing principles to optimize their processes. This comprehensive approach allows shipyards to stay agile and responsive, adapting to the constantly evolving needs of their clients and the broader market.

Unlocking the Full Potential of Shipbuilding with Robotic Welding

As I reflect on my experiences in the welding and fabrication industry, I can’t help but feel a deep sense of pride and excitement about the transformative potential of robotic welding in the shipbuilding sector. By blending the expertise of skilled human workers with the precision and efficiency of automated systems, we’re able to push the boundaries of what’s possible in this dynamic industry.

From streamlining complex welding processes to enhancing quality control and safety, robotic welding is helping to redefine the future of shipbuilding. And as we continue to explore the synergies between model-based manufacturing, lean management, and advanced automation, I’m confident that we’ll see even more innovative solutions emerge to tackle the challenges faced by this vital industry.

So, if you’re a fellow welder or metal fabricator working in the shipbuilding industry, I encourage you to embrace the power of robotic welding and the broader technological advancements that are shaping the future of our craft. By staying at the forefront of these innovations, we can not only contribute to the construction of the world’s most impressive maritime vessels but also ensure the long-term sustainability and success of our industry.

After all, as the heart of global trade and defense, the shipbuilding industry deserves nothing less than the finest welding and fabrication expertise. And with the help of robotic welding and model-based manufacturing, we’re well on our way to delivering just that.