As an experienced welder and metal fabricator, I’ve seen firsthand how the industry has evolved over the years. One of the most exciting advancements has been the integration of robotic welding, particularly in the shipbuilding sector. This innovative technology has truly revolutionized the way we approach fabrication, and I’m thrilled to share my insights with you.

The Automation Advantage

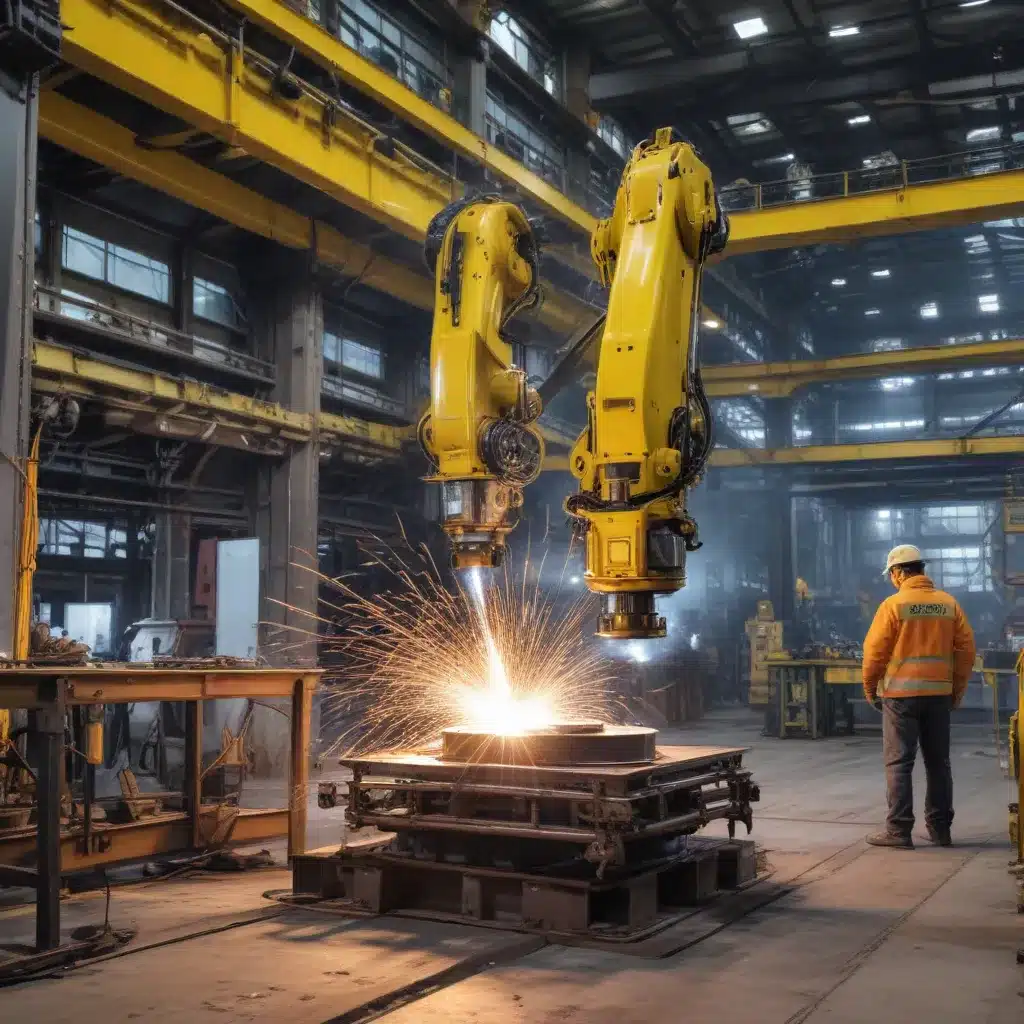

Gone are the days when welding was solely a manual process, reliant on the steady hands and keen eyes of skilled tradesmen. Today, the world of welding automation has taken center stage, and it’s easy to see why. By leveraging the power of robotic systems, we can achieve a level of precision and consistency that was previously unattainable.

Imagine a world where every weld is executed with unwavering accuracy, without the constraints of human fatigue or variation. That’s the beauty of robotic welding. These advanced systems are programmed to perform precise movements, maintaining the perfect angle, speed, and heat input, resulting in welds that are truly a work of art.

Shipbuilding’s Transformation

The shipbuilding industry has been a prime beneficiary of this technological revolution. In an environment where safety, quality, and efficiency are paramount, robotic welding has become an invaluable asset. From the construction of massive cargo vessels to the intricate assembly of luxury yachts, this automation has streamlined the fabrication process, driving unprecedented productivity.

As I reflect on my own experiences in this field, I can’t help but be in awe of the transformation I’ve witnessed. Gone are the days when shipyards were bustling with manual welders, each with their own unique style and approach. Now, the rhythmic hum of robotic arms and the precise movements of automated welding torches have become the symphony of modern shipbuilding.

Precision and Consistency

One of the standout features of robotic welding is its unparalleled precision. These systems are programmed to follow predetermined paths, ensuring that every single weld is executed with pinpoint accuracy. This level of consistency is crucial in the shipbuilding industry, where the structural integrity of the vessel is of paramount importance.

Imagine the challenges of manually welding the intricate frameworks and complex steel structures that make up a ship’s hull. Even the slightest variation in technique or hand-eye coordination can lead to inconsistencies that compromise the overall strength and durability of the final product. With robotic welding, however, we can virtually eliminate these concerns, delivering welds that are consistently strong, uniform, and free of defects.

Increased Productivity and Safety

In addition to the precision benefits, robotic welding has also had a profound impact on productivity and safety in the shipbuilding industry. These automated systems can work tirelessly, without the need for breaks or rest. They don’t experience fatigue or distraction, allowing for continuous, high-volume production that simply wasn’t feasible with manual welding.

Furthermore, the integration of robotic welding has significantly enhanced the safety of our operations. By removing human workers from the most hazardous welding tasks, we’ve drastically reduced the risk of injuries, such as burns, fumes exposure, and electric shocks. This not only protects our valued team members but also streamlines the overall fabrication process, minimizing downtime and disruptions.

Adaptability and Innovation

As with any industry-changing technology, the evolution of robotic welding has been an ongoing process. Shipbuilders and fabricators like myself have had to adapt and innovate to fully leverage the capabilities of these automated systems.

One of the key challenges we’ve had to overcome is the need for flexibility. While robotic welding excels at repetitive, high-volume tasks, accommodating unique or customized projects can be a bit more complex. However, through advancements in programming and sensor technologies, we’ve been able to develop robotic systems that can adapt to a wider range of welding requirements, ensuring that even the most intricate shipbuilding projects can benefit from the precision and consistency of automation.

Collaboration and Skill Development

It’s important to note that the integration of robotic welding doesn’t mean the end of the skilled welder. In fact, the successful implementation of this technology requires a seamless collaboration between human experts and automated systems. As welders and fabricators, we’ve had to evolve our skillsets, mastering the programming, troubleshooting, and maintenance aspects of these robotic welding solutions.

Gone are the days when we could simply rely on our physical prowess and years of experience. Now, we must also possess a deep understanding of the underlying technology, the ability to interpret sensor data, and the agility to adapt to changing production needs. This shift in skillset has been both exciting and challenging, but ultimately, it has elevated the role of the modern welder, transforming us into highly skilled technicians capable of extracting the full potential of robotic welding.

The Future of Welding Automation

As I look to the future, I’m confident that the advancements in robotic welding will continue to shape the landscape of the shipbuilding industry and beyond. With the global welding automation market expected to reach $117 billion by 2026, it’s clear that this technology is poised to become an essential component of modern manufacturing and construction.

The possibilities are truly limitless. Imagine a future where autonomous welding systems can operate with minimal human intervention, delivering x-ray quality welds with zero errors. Or envision a world where robots can seamlessly adapt to the most complex welding challenges, unlocking new levels of innovation and pushing the boundaries of what’s possible in fabrication.

At The Weld Fab, we’re at the forefront of this technological revolution, continuously pushing the envelope and exploring the frontiers of welding automation. Our team of experts is dedicated to developing cutting-edge solutions that not only enhance productivity and quality but also redefine the customer experience.

Whether you’re a seasoned shipbuilder or a newcomer to the industry, I encourage you to embrace the power of robotic welding and unlock the endless possibilities it offers. Together, we can elevate the art of metalworking, delivering unparalleled precision, efficiency, and innovation that will shape the future of fabrication.