Elevating the Craft of Metalworking

As an experienced welder and metal fabricator, I’ve seen the industry evolve over the years, with advancements in technology and automation transforming the way we approach our craft. While some may view these changes with apprehension, I’ve come to embrace them as opportunities to elevate the art of metalworking and deliver exceptional results for our clients.

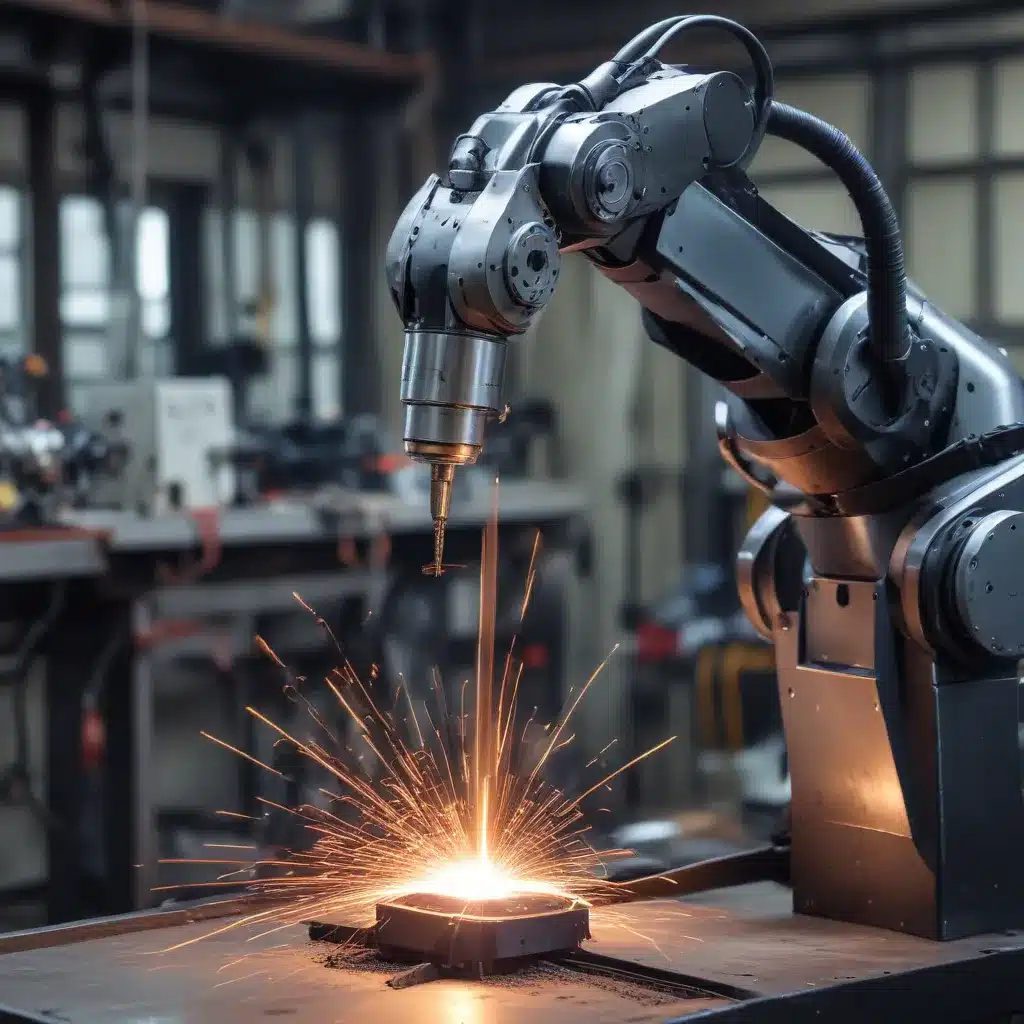

One of the most significant developments in our field has been the rise of collaborative robots, or cobots, in welding and fabrication. These innovative machines have not only enhanced our efficiency and productivity but have also allowed us to push the boundaries of what’s possible in terms of precision and quality.

When I first heard about cobots, I’ll admit, I was a bit skeptical. After all, I had built my career on the foundation of manual welding, honing my skills over countless hours of hands-on work. But as I learned more about the capabilities of these collaborative robots, I couldn’t help but be intrigued by the potential they offered.

Embracing the Power of Cobots

One of the key advantages of cobots in welding is their ability to provide consistent, high-quality results. Gone are the days of relying solely on the inherent variability of human performance. With a cobot, we can achieve a level of repeatability that simply wasn’t possible before. Each weld is executed with the same level of precision, ensuring that our final products meet the most stringent standards.

But it’s not just about the consistency of the welds themselves. Cobots have also revolutionized the way we approach the fabrication process as a whole. Their flexibility and adaptability allow us to seamlessly transition between different projects, quickly adjusting parameters and reprogramming the robot to tackle various tasks.

In our shop, I’ve seen firsthand how a cobot can dramatically reduce the time required to set up and execute a welding job. Gone are the days of tedious fixturing and endless adjustments. With the cobot’s intuitive programming and user-friendly interface, we can have a new project up and running in a matter of minutes, freeing up our skilled welders to focus on the more complex and challenging aspects of the work.

Enhancing Safety and Ergonomics

But the benefits of cobots go beyond just improving efficiency and productivity. They’ve also had a significant impact on the safety and ergonomics of our work environment.

As welders, we’re often tasked with performing physically demanding tasks, from heavy lifting to repetitive motions that can take a toll on our bodies over time. With a cobot handling the more physically taxing aspects of the job, our team can focus on the strategic and creative elements of the work, reducing the risk of injury and maintaining their well-being.

Driving Innovation in Fabrication

Perhaps one of the most exciting aspects of embracing cobots in our metalworking operations is the way they’ve inspired us to rethink our approach to fabrication. With the ability to quickly adapt and reconfigure our robotic systems, we’ve been able to tackle more complex and intricate projects that would have been nearly impossible using traditional methods.

I’ll never forget the time we were tasked with fabricating a custom stainless steel component for a high-end architectural project. The part featured a series of intricate curves and contours that would have been a nightmare to weld by hand. But with the help of our cobot, we were able to program a precise welding path that followed the complex geometry, resulting in a flawless finish that left our client astounded.

Fostering a Culture of Continuous Improvement

As we’ve integrated cobots into our welding and fabrication processes, I’ve witnessed a shift in the mindset of our team. Rather than seeing these automated systems as a threat to their livelihoods, our skilled welders have embraced them as tools that can amplify their talents and enable them to push the boundaries of what’s possible.

In fact, many of our team members have taken it upon themselves to learn the ins and outs of cobot programming, eager to explore the full extent of these machines’ capabilities. This culture of continuous learning and improvement has been a driving force behind our success, as we constantly seek new ways to optimize our workflows and deliver even higher levels of quality and precision.

Navigating the Challenges

Of course, integrating new technology into a well-established metalworking operation is not without its challenges. We’ve had to navigate a learning curve, both in terms of programming the cobots and in training our team to work seamlessly alongside these automated systems.

One of the key hurdles we’ve had to overcome is the perception that cobots are here to replace human welders. Nothing could be further from the truth. In our experience, these collaborative robots are most effective when they’re used to augment and enhance the skills of our talented team, not replace them.

By shifting the focus of our welders from the more repetitive and physically demanding tasks to the more strategic and creative aspects of the work, we’ve been able to unlock new levels of innovation and problem-solving. Our team members have embraced the opportunity to hone their skills, constantly seeking ways to optimize their techniques and push the boundaries of what’s possible.

Embracing the Future of Welding and Fabrication

As I look to the future of our industry, I’m excited to see the continued evolution of welding and fabrication technology. From advancements in cobot programming to the integration of advanced sensors and data analytics, the possibilities for enhancing precision, efficiency, and quality are truly limitless.

At https://theweldfab.com/, we’re committed to staying at the forefront of these developments, constantly exploring new ways to incorporate the latest innovations into our metalworking operations. By embracing the power of automation and technology, we’re not only driving our own success but also shaping the future of the industry as a whole.

So, whether you’re a seasoned welder or a newcomer to the field, I encourage you to keep an open mind and embrace the transformative potential of cobots and other advanced fabrication technologies. The future of metalworking is bright, and I’m proud to be a part of this exciting journey.