Revolutionizing Workplace Safety with Collaborative Robots and Intelligent Automation

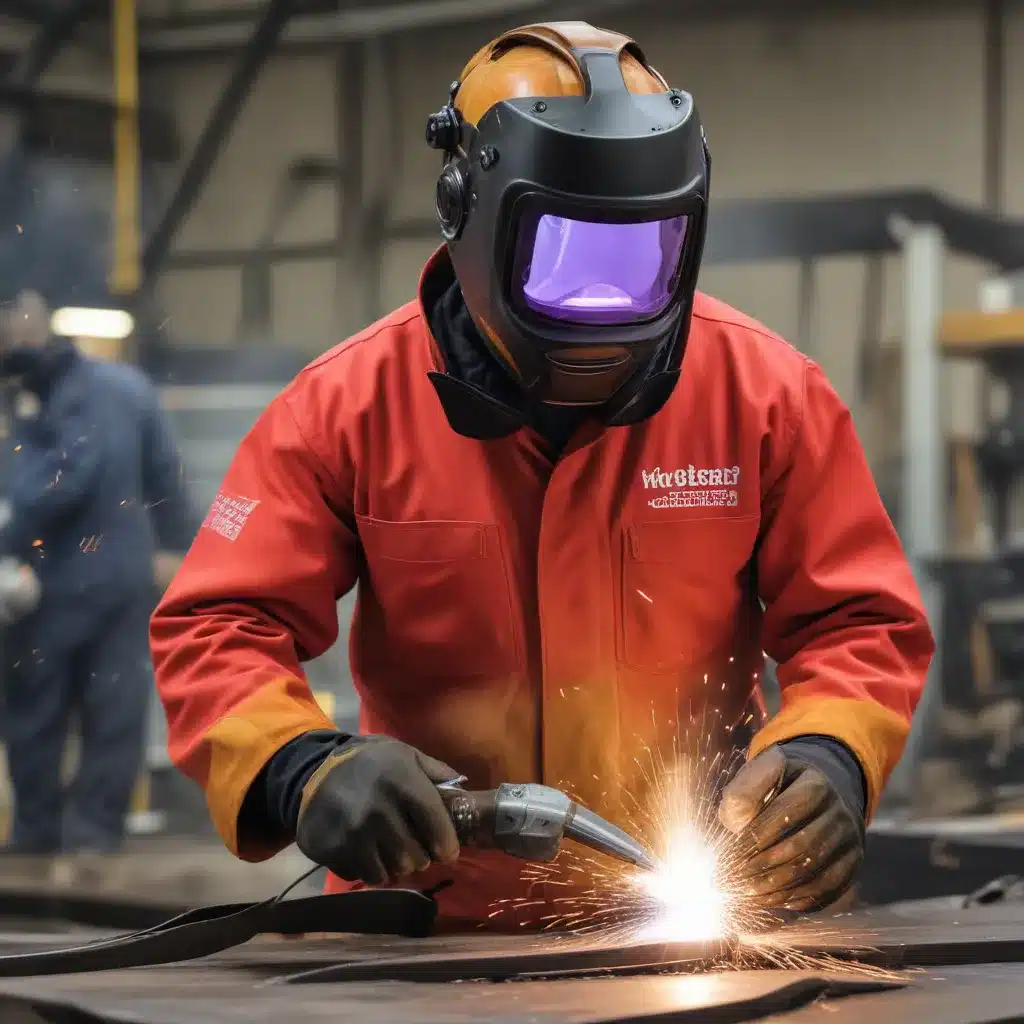

As an experienced welder and metal fabricator, I’ve seen my fair share of industry innovations over the years. But I have to say, the rise of cobots and AI-powered systems is truly reshaping the landscape when it comes to safeguarding workers in the factory. Gone are the days of relying solely on human vigilance and manual processes to mitigate risks – these cutting-edge technologies are proving to be game-changers in the quest for a safer, more productive shop floor.

Let me tell you, I’ve worked in this field long enough to know that keeping employees out of harm’s way is paramount. After all, a single injury can derail operations, lead to costly downtime, and dampen morale. That’s why I’m so excited to see how our industry is embracing the power of collaborative robots and artificial intelligence to proactively identify hazards and minimize dangerous interactions between people and machines.

These advanced systems are a far cry from the hulking, caged industrial robots of the past. Cobots, as they’re called, are designed specifically for human-machine collaboration, using sensors and sophisticated programming to navigate the workspace safely while complementing the unique skills of their human counterparts. And the incorporation of AI takes things to a whole new level, enabling real-time monitoring and instant reaction to potential emergencies.

Sure, the initial investment in these technologies may be higher than traditional safeguards, but the long-term payoff is undeniable. Not only do they virtually eliminate the risk of injuries from repetitive motions or machine-related accidents, but they also streamline workflow and boost overall efficiency. It’s a win-win for employers and employees alike.

Leveraging the Power of Wearable Tech for Proactive Safety

But it’s not just cobots and AI that are reshaping the safety landscape in our industry. Wearable devices like fitness trackers and smart PPE are also playing a crucial role in monitoring worker wellbeing and catching potential issues before they escalate.

I remember a few years back, one of our fabrication shops started outfitting their crew with smart hard hats and safety glasses. At first, some of the guys were a bit skeptical – they thought it was just another way for the bosses to keep tabs on them. But once they saw how these devices could detect early signs of fatigue, heat stress, or other health concerns, they quickly became converts.

The way it works is pretty ingenious. The wearables continuously track vital signs, environmental conditions, and movement patterns, sending real-time data to a centralized monitoring system. If the sensors pick up on anything concerning – like an elevated heart rate, irregular breathing, or a sudden drop in core body temperature – the system can instantly alert supervisors and trigger emergency protocols.

This kind of preemptive approach is so much more effective than relying on workers to self-report issues or waiting for a serious incident to occur. And let me tell you, it’s made a world of difference in our operation. Our incident rates have plummeted, and the crew knows that we’ve got their backs when it comes to staying safe on the job.

Fostering a Culture of Safety Through Collaboration and Transparency

Of course, implementing these advanced safety technologies is only half the battle. The real key is cultivating a workplace culture that empowers employees to take an active role in their own wellbeing and embraces transparency around potential risks.

That’s why we’ve made a concerted effort to educate our team on how the cobots, AI systems, and wearable devices work – not just from a technical standpoint, but also in terms of how the data is used to keep them safe. We want everyone to understand that this isn’t about surveillance or micromanagement, but rather a genuine commitment to their health and safety.

And you know what? Our workers have responded incredibly positively to this approach. They feel valued, they feel heard, and they know that we’re all in this together. Sure, there’s still the occasional skeptic who grumbles about the “Big Brother” aspects, but for the most part, our crew has really bought into the idea of these technologies as safety superstars rather than adversaries.

Tailoring Solutions to Fit Your Unique Needs

Of course, no two fabrication shops are exactly alike, and the specific safety challenges you face will depend on the nature of your work, the equipment you use, and the size and composition of your workforce. That’s why it’s so important to work with providers who can deliver truly customized solutions.

At The Weld Fab, we pride ourselves on our ability to engineer smart automation and wearable systems that align perfectly with our clients’ unique requirements. Whether you need specialized end-effectors for your cobots, advanced AI algorithms for risk monitoring, or a comprehensive training program to get your team up to speed, we’ve got you covered.

Our team of experts will work hand-in-hand with you to assess your current safety protocols, identify areas for improvement, and devise a tailored plan of action. We understand that every workplace is different, and what works like a charm in one shop may fall flat in another. That’s why we take the time to truly understand your operation, your pain points, and your long-term goals before proposing any solutions.

Unlocking the Full Potential of Human-Machine Collaboration

At the end of the day, the goal isn’t just to slap a few sensors on your workers and call it a day. It’s about fostering a culture of safety that empowers your team, optimizes your processes, and unlocks the full potential of human-machine collaboration.

When you’ve got cobots seamlessly handling the heavy lifting and dangerous tasks, your employees can dedicate their time and energy to more intricate, higher-value work. And with AI constantly monitoring operations and flagging issues in real-time, you can respond quickly to emergencies and make proactive adjustments to maintain peak performance.

But the real magic happens when you integrate these technologies into a comprehensive safety strategy that prioritizes transparency, education, and worker engagement. Because let’s face it, no matter how sophisticated the hardware and software, it’s the people on the shop floor who truly make the difference. By empowering them with the knowledge, tools, and confidence to stay safe, you’re not just protecting their wellbeing – you’re also unlocking new levels of productivity, efficiency, and innovation.

So if you’re ready to take your workplace safety to new heights and reap the rewards of cutting-edge automation and intelligent monitoring, I urge you to explore the solutions offered by The Weld Fab. Our team of industry experts is standing by to help you create a smarter, more secure environment where technology and human expertise work in perfect harmony. Let’s get started on your journey towards a safer, more prosperous future for your fabrication business!