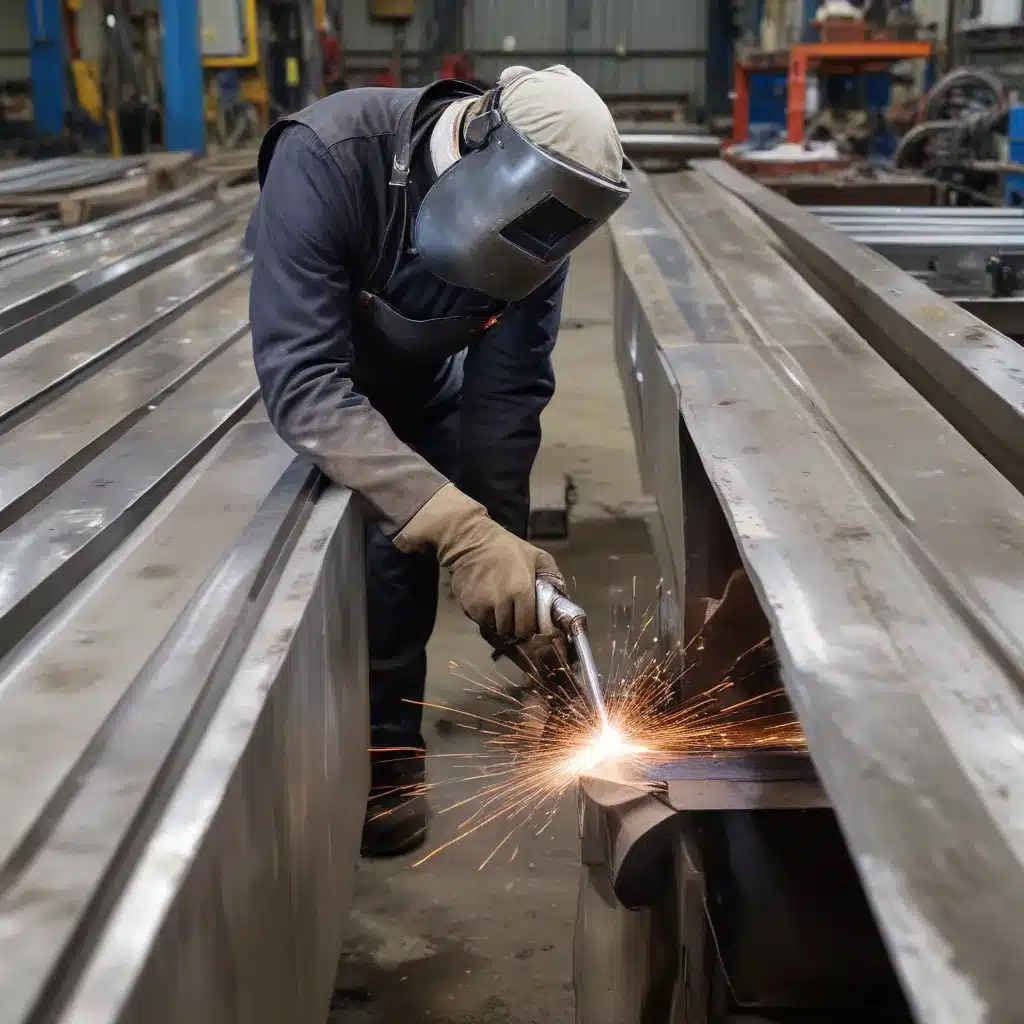

As an experienced welder and metal fabricator, I’ve had the privilege of working with a wide range of materials, each with its own unique set of challenges. But when it comes to welding stainless steel, I have to say, it’s a whole different ballgame. The level of precision and attention to detail required is truly remarkable, and it’s a craft that I’ve come to deeply respect over the years.

Mastering the Art of Stainless Steel Welding

Stainless steel is a material that demands the highest level of skill and expertise from a welder. Its inherent resistance to corrosion and its ability to maintain its structural integrity under extreme conditions make it an essential material in a variety of industries, from food processing to aerospace. But that same resistance that makes it so valuable also makes it incredibly difficult to work with.

One of the biggest challenges I’ve encountered in stainless steel welding is the issue of weld contamination. Stainless steel is highly susceptible to the formation of chromium carbides, which can weaken the weld and lead to corrosion. To prevent this, we have to be meticulous in our prep work, ensuring that the surface is meticulously clean and free of any contaminants. This means using the right cleaning agents, like solvents or abrasives, and following a strict protocol to ensure that every inch of the weld area is spotless.

Another critical factor in stainless steel welding is the selection of the right filler metal. The type of stainless steel you’re working with, as well as the specific application, will dictate the best filler to use. It’s a delicate balancing act, as the wrong filler can lead to a weak or brittle weld, while the right one can ensure the integrity and longevity of the final product.

Precision and Consistency: The Keys to Stainless Steel Welding

One of the things that sets stainless steel welding apart is the level of precision required. Every aspect of the process, from the positioning of the workpiece to the control of the welding parameters, has to be dialed in with laser-like accuracy. Even the slightest deviation can result in a subpar weld that doesn’t meet the industry’s rigorous standards.

To achieve this level of precision, we rely heavily on our expertise and the advanced technology at our disposal. High-end welding machines with precise arc control and computerized monitoring systems are essential tools in our arsenal. But it’s not just about the equipment – it’s also about the skill and experience of the welder themselves.

I’ve spent countless hours perfecting my technique, fine-tuning my movements and adjusting my parameters to achieve the perfect weld every time. It’s a constant learning process, as the demands of the industry evolve and new challenges arise. But that’s what keeps me passionate about this work – the never-ending pursuit of perfection.

The Importance of Quality Control in Stainless Steel Fabrication

In the world of stainless steel fabrication, quality control is not just a buzzword – it’s a way of life. Every weld, every joint, every finished product is subject to rigorous testing and inspection to ensure that it meets the highest standards of safety and performance.

One of the key tools we use in our quality control process is non-destructive testing (NDT). This allows us to detect any flaws or defects in the weld without compromising the structural integrity of the final product. From ultrasonic testing to x-ray analysis, we leave no stone unturned in our quest for perfection.

But quality control isn’t just about the technical aspects of the job – it’s also about the human element. That’s why we place such a strong emphasis on training and certification for our welders. Every member of our team is required to undergo extensive testing and recertification to ensure that they’re always operating at the highest level of skill and proficiency.

The Rewards of Stainless Steel Welding

Despite the challenges and the relentless pursuit of perfection, there’s a deep sense of satisfaction that comes with mastering the art of stainless steel welding. When you see a finished product that’s not only visually stunning but also engineered to withstand the toughest conditions, it’s a feeling that’s hard to describe.

I take pride in knowing that the work we do at The Weld Fab plays a crucial role in the construction of the infrastructure that powers our world, from the food processing equipment that keeps our kitchens running to the aerospace components that soar through the skies. And with each project we undertake, we’re constantly pushing the boundaries of what’s possible, finding new and innovative ways to tackle the unique challenges that stainless steel presents.

Embracing the Complexity

At the end of the day, welding stainless steel is not for the faint of heart. It’s a craft that requires a deep understanding of metallurgy, a keen eye for detail, and an unwavering commitment to quality. But for those of us who have dedicated our careers to this pursuit, it’s a challenge that we embrace with open arms.

After all, what could be more rewarding than transforming raw materials into functional, high-performance products that will stand the test of time? It’s a responsibility that we take very seriously, and it’s a legacy that we’re proud to be a part of.

So if you’re a fellow welder or fabricator, I salute you. Keep pushing the boundaries, keep striving for perfection, and never lose sight of the incredible impact that our work can have on the world around us. And if you’re just starting out in this industry, I encourage you to dive in headfirst – the rewards, both personal and professional, are truly unparalleled.

Conclusion

Welding stainless steel is a unique and complex challenge, but it’s one that I’ve come to deeply appreciate over the course of my career. From the meticulous attention to detail required to the rigorous quality control processes, every aspect of this craft demands the utmost skill and expertise.

But for those of us who have dedicated ourselves to this pursuit, the rewards are truly unparalleled. Whether it’s the satisfaction of seeing a finished product that embodies the pinnacle of precision and performance, or the knowledge that our work is contributing to the advancement of critical industries, there’s a sense of pride and accomplishment that simply can’t be matched.

So if you’re a fellow welder or fabricator, I encourage you to embrace the complexity of stainless steel welding and to never stop pushing the boundaries of what’s possible. And if you’re just starting out in this industry, I invite you to explore the world of The Weld Fab – where precision, quality, and innovation come together to create something truly remarkable.