Embracing the Power of Automation in Construction Fabrication

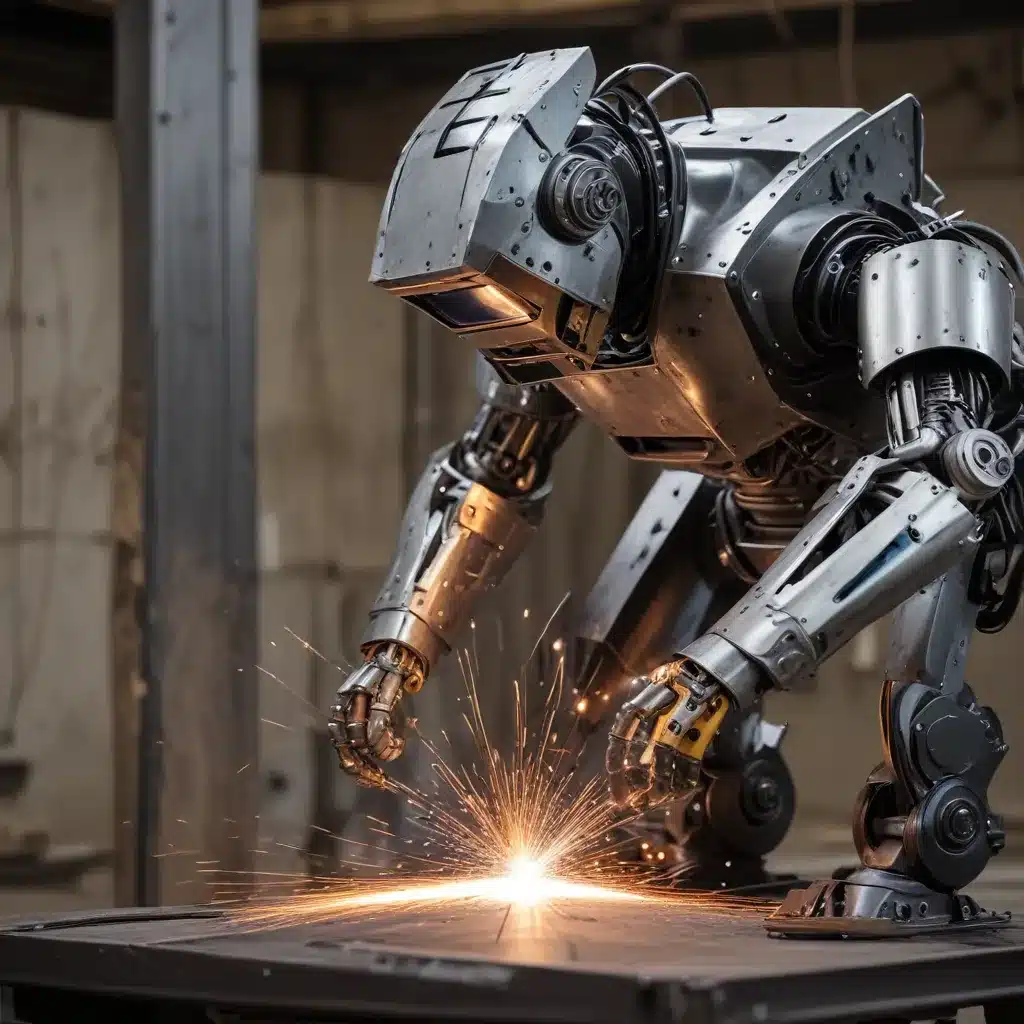

As an experienced welder and metal fabricator, I’ve witnessed firsthand the transformative impact of robotic welding and fabrication technologies on the construction industry. Gone are the days when construction relied solely on manual labor – today, we’re ushering in a new era of efficiency, precision, and innovation that is revolutionizing the way we approach structural integrity.

When I first started in this field, welding was a physically demanding task that required immense skill and experience. Hours upon hours were spent meticulously aligning components, striking the perfect arc, and ensuring every weld met the strictest standards. But now, the integration of robotic systems has completely transformed the landscape, empowering us to tackle even the most complex construction projects with unparalleled speed and accuracy.

The Rise of Arc Welding Robots: Versatility and Precision Redefined

One of the game-changers in the construction industry has been the introduction of arc welding robots. These versatile machines have become the backbone of structural fabrication, seamlessly handling a wide range of welding processes with uncompromising precision. Their ability to adapt to various joint configurations, material thicknesses, and welding positions has made them an indispensable tool in the construction arsenal.

What I find most impressive about arc welding robots is their efficiency. Gone are the days of physically exhausting manual welding – these robotic systems can work tirelessly, day and night, with a level of consistency that far surpasses human capabilities. The result? Streamlined production, reduced lead times, and a level of quality that is simply unmatched.

But it’s not just the speed and efficiency that make arc welding robots so valuable in construction. Their precision is truly remarkable. I’ve seen these machines lay down weld beads with laser-like accuracy, ensuring the structural integrity of critical components like beams, columns, and pipe joints. This level of precision is especially crucial in large-scale projects, where even the slightest deviation can have catastrophic consequences.

Spot Welding Robots: Revolutionizing Sheet Metal Fabrication

While arc welding robots have transformed the way we handle structural steel, spot welding robots have become the champions of sheet metal fabrication in construction. These high-speed, automated systems have revolutionized the assembly of components like facades, cladding, and HVAC ductwork, delivering consistent, reliable welds with unparalleled efficiency.

What I love about spot welding robots is their ability to handle repetitive tasks with lightning-fast precision. Gone are the days of manually spot welding sheet metal components – these robotic systems can churn out consistent, high-quality welds in a fraction of the time, freeing up our skilled welders to tackle more complex and specialized tasks.

But it’s not just the speed and consistency that make spot welding robots so valuable in construction. Their ability to work in confined spaces and on intricate geometries has made them indispensable for projects that require a delicate touch. I’ve seen these robots navigate the most intricate architectural metalwork, delivering flawless welds with a level of precision that simply can’t be matched by human hands.

Laser Welding Robots: Precision, Efficiency, and Aesthetic Appeal

As if arc welding and spot welding robots weren’t impressive enough, the construction industry has also embraced the power of laser welding robots. These advanced systems utilize high-powered lasers to join metal components with unparalleled accuracy and efficiency, making them the go-to solution for specialized applications that demand the utmost precision and aesthetic appeal.

What I find most remarkable about laser welding robots is their ability to create seamless, virtually invisible welds. The narrow heat-affected zones and clean, consistent bead profiles they produce have made them a game-changer in the world of architectural metalwork, where the aesthetic appearance of a structure is just as important as its structural integrity.

But it’s not just the visual appeal that makes laser welding robots so valuable in construction. Their efficiency and precision also play a crucial role in optimizing production processes and reducing costs. I’ve seen these systems slice through thick metal plates with surgical precision, delivering consistent, high-quality welds that meet the most demanding industry standards.

Plasma Cutting Robots: The Precision Specialists

While welding may be the heart of construction fabrication, the art of cutting metal components is equally crucial. That’s where plasma cutting robots have emerged as the unsung heroes of the industry, offering a level of precision and efficiency that has simply revolutionized the way we approach material preparation.

What I love about plasma cutting robots is their versatility. These machines can slice through a wide range of metal materials, from thick structural steel to delicate architectural elements, with a level of accuracy that is simply breathtaking. Their ability to deliver clean, precise cuts has not only streamlined our production processes but has also opened up new possibilities in terms of design and fabrication.

But it’s not just the cutting capabilities that make plasma cutting robots so valuable in construction. Their speed and efficiency have also played a crucial role in reducing lead times and driving down costs. I’ve seen these robots churn out intricate cut components in a fraction of the time it would take using traditional manual methods, all while maintaining a level of precision that is simply unmatched.

The Rise of 3D Printing Robots: Redefining the Limits of Construction

As if welding and cutting robots weren’t enough to revolutionize the construction industry, the emergence of 3D printing robots has taken the art of fabrication to entirely new heights. These cutting-edge systems are now able to produce complex, custom-designed structures with a level of efficiency and precision that was once the stuff of science fiction.

What truly amazes me about 3D printing robots is their ability to create structures that simply defy the limits of traditional construction methods. I’ve seen these machines produce intricate architectural elements, complex geometries, and even entire load-bearing components, all with a level of precision and detail that is simply breathtaking.

But it’s not just the design capabilities of 3D printing robots that have captivated the construction industry. Their ability to reduce material waste and accelerate construction timelines has also made them an invaluable asset in the pursuit of sustainable, cost-effective building practices. By optimizing material usage and streamlining the fabrication process, these robots are ushering in a new era of construction efficiency that promises to transform the way we approach the built environment.

Automated Material Handling: Streamlining Logistics and Enhancing Safety

As impressive as the welding, cutting, and 3D printing robots may be, the construction industry has also embraced the power of automated material handling systems to streamline logistics and enhance safety on construction sites. These robotic systems have revolutionized the way we manage the flow of materials, ensuring that the right components are delivered to the right place at the right time.

What I find most remarkable about automated material handling robots is their ability to optimize material flow and reduce the reliance on manual labor. I’ve seen these machines navigate complex construction sites with precision and efficiency, seamlessly coordinating the delivery of materials and minimizing the risk of workplace injuries. This not only enhances productivity but also contributes to a safer, more secure working environment for our team.

But it’s not just the logistics and safety benefits that make automated material handling robots so valuable in construction. Their integration with other robotic systems, such as welding and cutting machines, has also enabled us to create truly integrated, end-to-end fabrication solutions that maximize efficiency and minimize downtime.

Robotic Rebar Processing and Placement: Revolutionizing Concrete Reinforcement

As if the realm of welding, cutting, and material handling robots wasn’t impressive enough, the construction industry has also embraced the power of robotic rebar processing and placement systems to revolutionize the way we handle reinforcement bars (rebar) in concrete structures.

These advanced robotic systems have truly transformed the way we approach rebar fabrication and installation, offering a level of precision, speed, and safety that was simply unattainable using traditional manual methods. I’ve seen these machines effortlessly cut, bend, and place rebar with laser-like accuracy, ensuring that the reinforcement is positioned exactly where it needs to be to optimize structural performance.

But it’s not just the efficiency and precision that make robotic rebar processing and placement systems so valuable in construction. Their ability to enhance safety on the job site has also been a game-changer. By automating these physically demanding tasks, we’ve been able to reduce the risk of injuries and create a safer working environment for our team, all while delivering construction projects of exceptional quality and durability.

Embracing the Future: Welding and Fabrication in the Digital Age

As I reflect on the remarkable advancements in robotic welding and fabrication technologies that have transformed the construction industry, I can’t help but feel a deep sense of pride and excitement for what the future holds. The integration of these cutting-edge systems has not only streamlined our processes, enhanced our precision, and improved our safety – it has also opened up entirely new realms of design and innovation.

Think about it – with the power of robotic welding, cutting, and 3D printing at our fingertips, the possibilities for architectural expression and structural performance are truly limitless. We can now push the boundaries of what’s possible, crafting intricate, visually stunning structures that defy the constraints of traditional construction methods.

But it’s not just about the aesthetics – the impact of these robotic technologies on the overall quality and durability of construction projects is equally profound. By ensuring the precise alignment of components, the consistent application of welds, and the seamless integration of reinforcement, we’re able to create structures that are not only visually stunning but also engineered to withstand the test of time.

As we continue to embrace the power of automation and digital technologies in construction fabrication, I can’t wait to see what the future holds. Will we witness the rise of fully autonomous construction sites, where robots handle every aspect of the build? Will 3D printing revolutionize the way we approach architectural design, unlocking new realms of creativity and sustainability?

One thing is for certain – the integration of robotic welding and fabrication technologies is not just a passing fad, but rather a transformative force that is reshaping the very foundation of the construction industry. And as a seasoned welder and fabricator, I couldn’t be more excited to be a part of this revolution, shaping the built environment one weld at a time.

So, if you’re ever feeling curious about the cutting edge of construction technology, I encourage you to explore the world of robotic welding and fabrication. Trust me, you’ll be amazed at the level of precision, efficiency, and innovation that these systems bring to the table. And who knows – you might just find yourself as captivated by this ever-evolving field as I am.