As an experienced welder and metal fabricator, I’ve witnessed firsthand the profound impact that Industry 4.0 has had on our industry. Gone are the days of relying solely on manual processes and traditional tools – the digital revolution has ushered in a new era of efficiency, precision, and innovation in structural steel fabrication.

Automation and the Rise of Robotic Welding

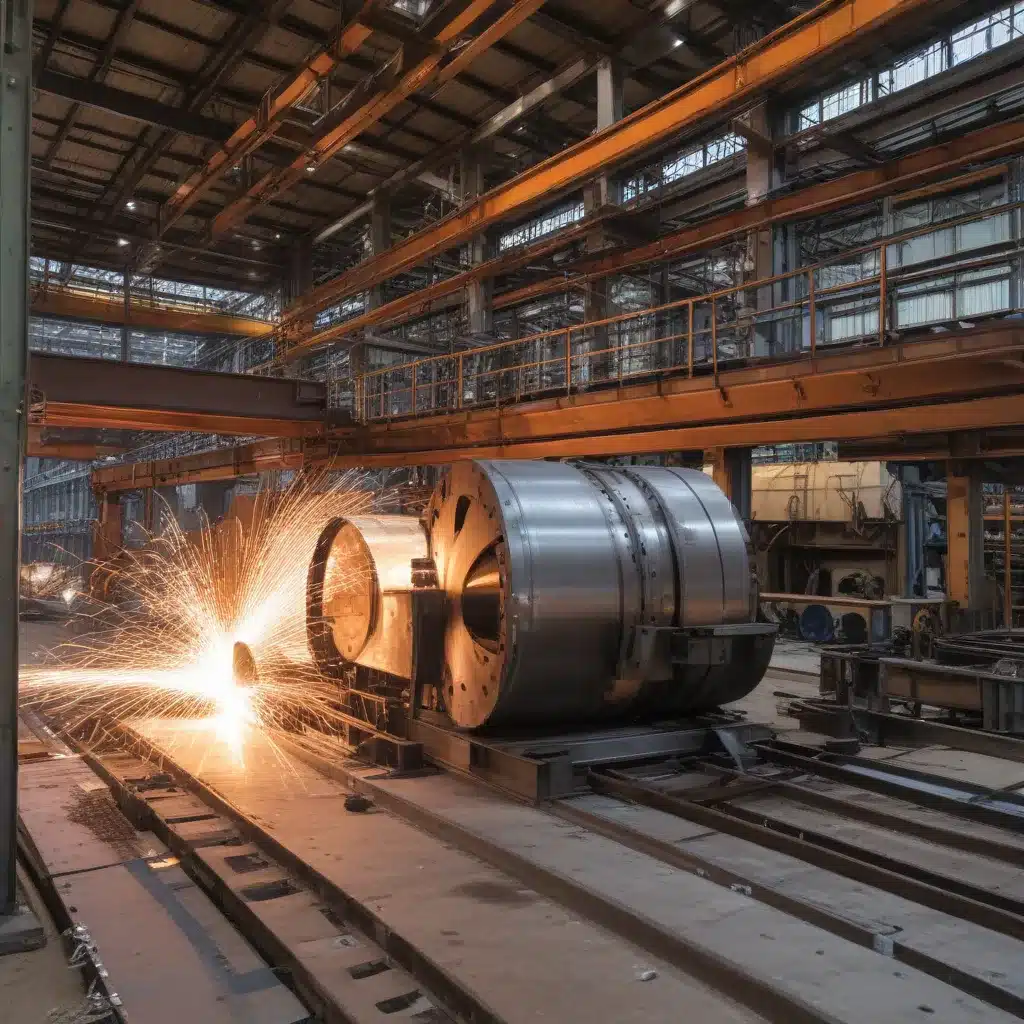

One of the most significant advancements in our field has been the integration of robotic welding systems. These automated welding cells have revolutionized the way we approach complex fabrication projects. By combining precision motion control, advanced sensors, and sophisticated programming, robotic welders can deliver consistently high-quality welds with remarkable speed and efficiency.

I remember the early days of introducing robotic welding to our shop floor. At first, there was a bit of hesitation and skepticism from some of the seasoned welders – after all, we had grown accustomed to the tactile feedback and manual dexterity that comes with traditional welding. However, as we delved into the capabilities of these robotic systems, we quickly realized the immense benefits they offered.

The repeatability and accuracy of robotic welders are truly astounding. Gone are the days of meticulously measuring and marking every weld joint – the robotic arm can follow a pre-programmed path with pinpoint precision, ensuring perfect alignment and consistent weld quality across an entire project. This has not only streamlined our fabrication workflows but has also significantly reduced the risk of costly rework or failures.

Moreover, the integration of advanced sensors and real-time monitoring systems has allowed us to closely track the performance of our robotic welders. By analyzing data on weld parameters, arc characteristics, and even potential defects, we can proactively identify and address any issues, maintaining the highest standards of quality control.

Embracing Lean Manufacturing Principles

Industry 4.0 has also influenced the way we approach the broader manufacturing process. By incorporating lean principles and data-driven decision making, we’ve been able to optimize our fabrication workflows and eliminate waste at every stage.

One of the key aspects of our lean transformation has been the implementation of Kanban systems. Rather than relying on a traditional push-based production model, we’ve adopted a pull-based approach, where material and information flow seamlessly through the fabrication process, responding to real-time customer demand.

This has enabled us to reduce lead times, minimize work-in-progress inventory, and improve overall responsiveness to our clients’ needs. By closely tracking key performance indicators such as cycle time, throughput, and on-time delivery, we can continuously refine our processes and identify areas for improvement.

Additionally, the use of digital twins and simulation tools has allowed us to experiment with process modifications and optimize material handling, work cell layouts, and material flow without disrupting our actual production. This has been an invaluable asset, enabling us to make data-driven decisions and implement changes with confidence, ultimately enhancing the overall efficiency of our fabrication facility.

Embracing the Power of Data and Analytics

One of the most transformative aspects of Industry 4.0 has been the proliferation of data and the ability to leverage it for informed decision-making. By integrating comprehensive data collection systems across our fabrication operations, we’ve gained unprecedented visibility into every facet of our processes.

From real-time monitoring of machine performance and energy consumption to detailed tracking of material usage and waste, the wealth of data at our fingertips has empowered us to make more informed, data-driven decisions. This has not only improved our operational efficiency but has also enabled us to identify opportunities for cost savings and sustainability enhancements.

For instance, by analyzing energy consumption patterns across our welding stations and fabrication equipment, we’ve been able to optimize our power usage and implement targeted energy-saving measures. This has not only reduced our environmental impact but has also contributed to significant cost savings that we can reinvest into the business.

Moreover, the integration of predictive maintenance algorithms has allowed us to anticipate equipment failures and proactively schedule preventive maintenance, minimizing unplanned downtime and ensuring the reliability of our fabrication processes. By leveraging the power of data analytics, we can now make more informed, data-driven decisions that align with our strategic goals and customer expectations.

Enhancing the Customer Experience

While the technological advancements of Industry 4.0 have undoubtedly transformed the way we approach structural steel fabrication, the true impact can be seen in the enhanced customer experience we are able to deliver.

By streamlining our fabrication workflows, improving quality control, and optimizing lead times, we’ve become a more reliable and responsive partner for our clients. Our customers now have unprecedented visibility into the status of their projects, with real-time updates and transparent communication throughout the fabrication process.

Furthermore, the integration of online portals and collaborative design tools has empowered our clients to actively participate in the fabrication process, providing feedback, suggesting design modifications, and even visualizing the final product before it’s even been manufactured.

This collaborative approach has fostered a stronger relationship between our fabrication team and our clients, ensuring that we are aligned on project goals, quality expectations, and delivery timelines. It’s a far cry from the traditional “black box” approach, where clients would simply place an order and wait anxiously for the final product.

Embracing the Future of Structural Steel Fabrication

As I reflect on the journey we’ve taken as a fabrication company, I’m truly inspired by the transformative power of Industry 4.0. The integration of advanced technologies, lean manufacturing principles, and data-driven decision-making has not only enhanced our operational efficiency but has also elevated the level of service and quality we can provide to our customers.

Looking ahead, I’m excited to see how the continued advancements in areas like additive manufacturing, augmented reality, and machine learning will further shape the future of structural steel fabrication. The possibilities are endless, and I’m eager to be at the forefront of this technological revolution, constantly pushing the boundaries of what’s possible in our industry.

At the heart of it all, though, is a deep passion for the art of metal fabrication. The inherent satisfaction of transforming raw materials into intricate, precision-engineered structures is what drives us, and the advancements of Industry 4.0 have only served to amplify that sense of pride and craftsmanship.

As we forge ahead into this new era, I invite you to join me in embracing the future of structural steel fabrication. Together, let’s uncover the endless possibilities that lie ahead, leveraging the power of technology to elevate our craft and deliver unparalleled solutions to our customers.

After all, https://theweldfab.com/ isn’t just a place – it’s a community of passionate metal fabricators and welders who are committed to pushing the boundaries of what’s possible. So, let’s roll up our sleeves, fire up the welding torches, and get to work on shaping the future, one precision-crafted structure at a time.