Unleashing Precision and Efficiency in Welding Large-Scale Steel Structures

As an experienced welder and metal fabricator, I’ve witnessed firsthand the remarkable advancements in robotic welding technology and how it has transformed the way we approach complex structural steel projects. Gone are the days of relying solely on manual welding techniques, which can be time-consuming, inconsistent, and expose workers to hazardous conditions. The rise of intelligent, automated welding systems has ushered in a new era of precision, efficiency, and safety – and I’m excited to share my insights with you.

In the dynamic and ever-evolving world of the offshore wind industry, the demand for robust, large-scale steel structures has never been higher. Foundations like monopiles and jackets, along with critical infrastructure like substations, must be manufactured to the highest standards of quality and safety to withstand the harsh marine environments. This presents a unique set of challenges for companies like ours, who are constantly seeking ways to push the boundaries of what’s possible in metal fabrication.

Overcoming the Limitations of Manual Welding

Traditional welding methods, reliant on manual labor, have long been a bottleneck in the production of these massive steel structures. The sheer size and complexity of the components involved make it incredibly difficult to maintain consistent weld quality and achieve the necessary production rates to meet tight deadlines. Inconsistencies in the welding process can compromise the structural integrity of the final product, which is simply unacceptable when it comes to mission-critical infrastructure.

Moreover, the physical demands of manually welding large-scale steel structures take a toll on our workers, exposing them to hazardous conditions and the risk of injury. As the offshore wind industry continues to grow, the availability of skilled welders has become increasingly scarce, further exacerbating the challenges we face.

Embracing the Power of Robotic Welding

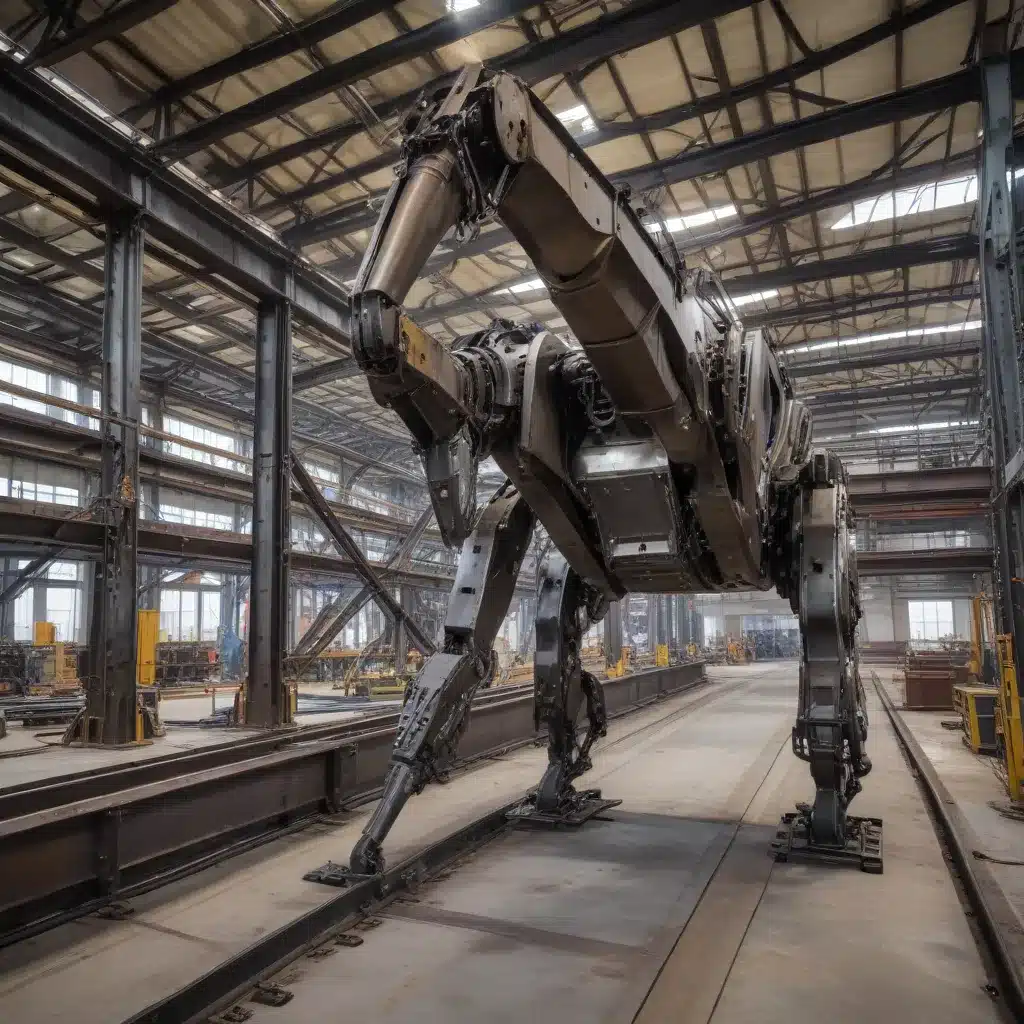

To address these challenges, we’ve made a strategic investment in the Inrotech-Column-Boom robotic welding system, a technology specifically designed for longitudinal welds on wind foundations. The versatility and precision of these robotic welders have been game-changers for our operation, allowing us to consistently deliver high-quality welds while dramatically improving our production efficiency.

Automated Scanning and Adaptive Welding

One of the standout features of the Inrotech-Column-Boom system is its ability to scan the tulip groove to be welded and conduct a detailed analysis to identify its key features and significant points. This allows the robot to determine the most optimal welding parameters and the appropriate distribution of weld passes, ensuring a seamless and consistent weld every time.

But what really sets this technology apart is its ability to adapt in real-time. Should the groove geometry change during the welding process due to deformation, the system’s WeldLogic technology detects these changes and automatically adjusts the welding parameters accordingly. This means we can allocate more resources and manpower to other critical tasks, optimizing time management and maximizing the overall productivity of our welding processes.

Eliminating the Need for Manual Programming

Another remarkable aspect of the Inrotech-Column-Boom system is its ability to operate without the need for extensive pre-programming. Unlike traditional robotic welding systems, which require time-consuming programming before each weld, these robots can simply scan the work area and generate a comprehensive set of welding parameters on the fly.

This dramatically reduces the setup time between tasks, enabling our team to maintain a consistent, uninterrupted production flow. It’s a level of flexibility and efficiency that simply wasn’t possible with our previous manual welding methods.

Delivering Consistent, High-Quality Welds

As a welder, I take immense pride in the quality of our work, and the Inrotech-Column-Boom system has allowed us to elevate our standards to new heights. By eliminating the variability inherent in manual welding, we can now produce welds with unparalleled consistency, ensuring the structural integrity and safety of the final product.

Moreover, the ability to adapt to changing groove geometries in real-time means we can maintain this level of precision even in the face of unexpected deformations or challenges. It’s a reassuring level of control that gives our clients the confidence they need to trust us with their most critical projects.

Optimizing Time and Resources

One of the most remarkable aspects of the Inrotech-Column-Boom system is its ability to optimize our time and resources, allowing us to focus on other critical tasks while the robots handle the welding. By automating the scanning, analysis, and welding processes, we can free up our skilled welders to tackle other aspects of the project, such as complex fabrication, quality control, and project management.

This increased efficiency has been a game-changer for us, enabling us to take on more projects, meet tighter deadlines, and ultimately provide a higher level of service to our clients. It’s a win-win situation – our clients get the high-quality, on-time results they demand, and our team can take pride in delivering exceptional work.

Fostering a Culture of Continuous Improvement

At the heart of our success with the Inrotech-Column-Boom system is a deep-rooted commitment to continuous improvement and innovation. We’re constantly exploring new ways to push the boundaries of what’s possible in the realm of metal fabrication, always striving to find more efficient, more precise, and safer ways to tackle even the most complex structural steel projects.

Whether it’s exploring the latest advancements in welding technology, optimizing our workflows, or investing in the training and development of our team, we’re always looking for ways to stay ahead of the curve. After all, in an industry as dynamic and competitive as ours, standing still simply isn’t an option.

Embracing the Future of Welding and Fabrication

As I look towards the future of our industry, I can’t help but feel a sense of excitement and optimism. The rapid advancements in robotic welding technology, combined with the increasing demand for large-scale, high-quality steel structures, have created a perfect storm of opportunity for companies like ours.

By embracing the power of automation and leveraging the precision and efficiency it offers, we’re able to not only meet the growing needs of the offshore wind industry but also push the boundaries of what’s possible in metal fabrication. It’s a thrilling time to be a welder and metal fabricator, and I can’t wait to see what the future holds.

So, if you’re a fellow welder or fabricator looking to take your operation to the next level, I encourage you to explore the world of robotic welding technology. The benefits are clear – improved consistency, increased efficiency, and a safer working environment for your team. And who knows, maybe one day, you’ll be the one sharing your own experiences and insights about how this transformative technology has propelled your business to new heights.

Until then, keep your torches lit, your steel primed, and your passion for precision welding burning bright. The future of our industry is bright, and I’m honored to be a part of it.