As an experienced welder and metal fabricator, I’ve had the privilege of witnessing firsthand the incredible advancements in our industry. From the evolution of cutting-edge techniques to the integration of innovative technologies, the world of metal shaping has undergone a remarkable transformation. In this article, I’ll share my personal insights and experiences, exploring the breakthroughs that are redefining the boundaries of what’s possible in metal forming and bending.

Mastering the Art of Precision Bending

One of the most critical aspects of modern metal fabrication is the ability to shape and bend metal with unparalleled precision. Whether we’re crafting intricate components for the aerospace industry or designing sleek enclosures for cutting-edge electronics, the demand for exceptional bending capabilities has never been higher.

I’ll never forget the first time I used a state-of-the-art press brake to form a complex part for a client. The level of control and repeatability was simply astounding. With the help of advanced computer-controlled systems, we were able to achieve tight tolerances and consistent bend angles that would have been unimaginable just a few years ago. The ability to program specific bend sequences and customize the tooling to our exact specifications has truly revolutionized the way we approach metal shaping.

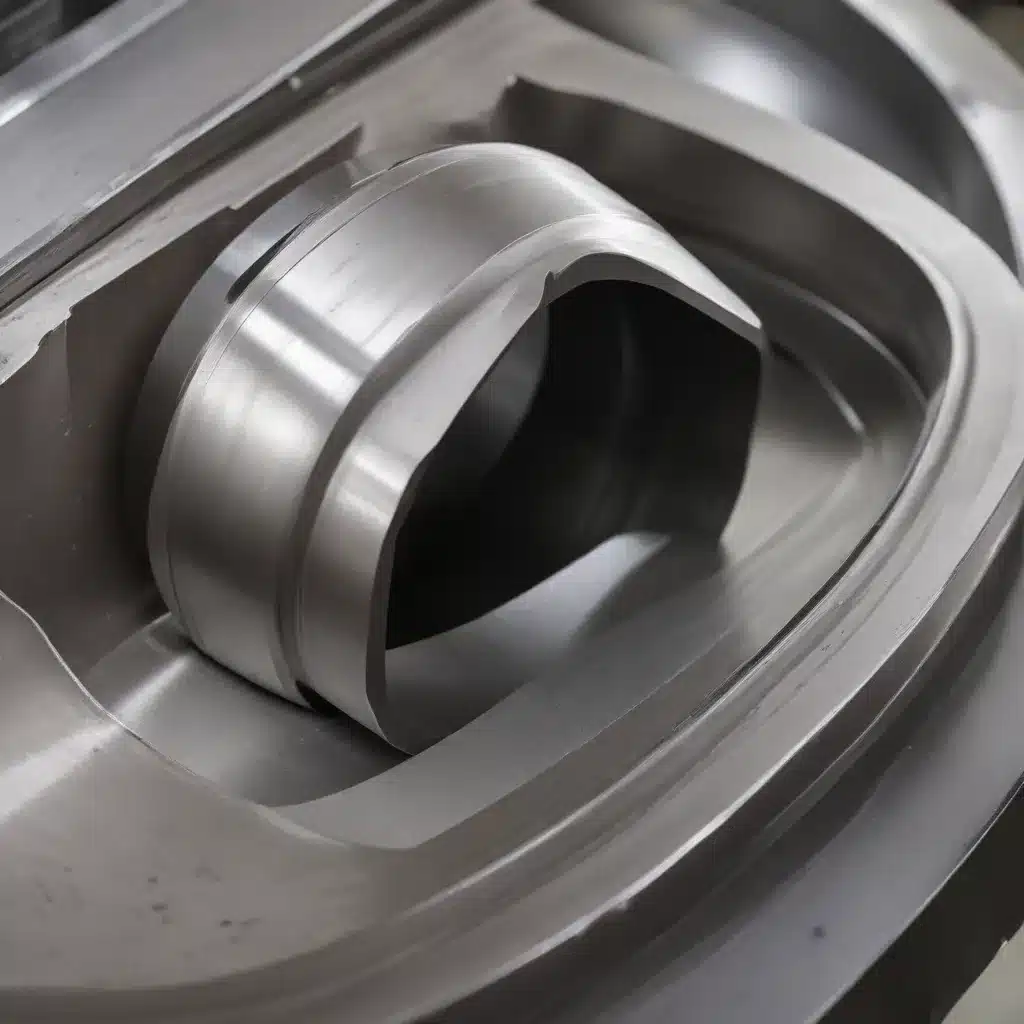

But it’s not just the press brake that has seen remarkable advancements. Techniques like roll forming have also become integral to our operations, allowing us to efficiently produce long, complex profiles with remarkable speed and consistency. By carefully designing the roll tooling and optimizing the process parameters, we can create parts that seamlessly integrate into our clients’ assemblies, reducing the need for additional fabrication or post-processing steps.

Unlocking Design Possibilities with Flexible Forming

As a seasoned metal fabricator, I’ve always been fascinated by the interplay between design and engineering. The ability to transform a simple flat sheet into a three-dimensional, functional component is nothing short of remarkable. And with the continued evolution of forming technologies, the design possibilities are expanding at an exponential rate.

Take, for example, the growing popularity of hydroforming. This process, which uses high-pressure fluid to shape metal, has opened up a whole new realm of design opportunities. By harnessing the power of hydraulics, we can create intricate shapes and complex geometries that would be nearly impossible to achieve through traditional stamping or bending methods. From seamless automotive body panels to intricate heat exchangers, the versatility of hydroforming is truly astounding.

But the true game-changer in metal forming has been the integration of advanced simulation and modeling software. By leveraging the power of computational fluid dynamics and finite element analysis, we can now predict material behavior, optimize tooling designs, and mitigate potential defects before a single part is produced. This virtual prototyping capability has not only streamlined our design process but has also dramatically reduced the time and cost associated with physical tryouts.

Embracing the Future of Metal Shaping

As I reflect on the incredible advancements in metal forming and bending, I can’t help but feel a sense of excitement for the future. The integration of cutting-edge technologies like artificial intelligence and additive manufacturing is set to redefine the way we approach metal fabrication.

Imagine a world where AI-driven systems can analyze real-time data from our production lines, identifying subtle variations in material properties or tool wear and automatically adjusting process parameters to maintain optimal quality and consistency. Or consider the potential of hybrid manufacturing, where we can combine the precision of traditional forming techniques with the design freedom of 3D printing to create parts that push the boundaries of what’s possible.

The possibilities are truly endless, and I can’t wait to see what the next generation of metal fabricators will achieve. By embracing these technological advancements and continuously pushing the limits of what’s possible, we can elevate our craft to new heights, delivering the high-quality, innovative solutions that our clients have come to expect from The Weld Fab.

Maintaining Quality and Precision in Metal Fabrication

Of course, as we explore these exciting new frontiers in metal shaping, it’s crucial that we never lose sight of the importance of quality and precision. After all, these are the cornerstones of our profession, the principles that have guided us through every challenge and setback.

That’s why we’ve invested heavily in the latest metrology equipment and quality control measures. From coordinate measuring machines (CMMs) that can capture the intricate details of our parts to advanced vision systems that can detect the slightest imperfections, we leave no stone unturned in our quest for perfection.

But it’s not just about the technology – it’s about the people behind it. Our team of skilled welders, fabricators, and quality assurance specialists are the true heart and soul of our operation. They’re the ones who meticulously inspect each component, who relentlessly chase down the slightest anomaly, and who take immense pride in delivering flawless work to our clients.

Forging Ahead with Passion and Innovation

As I look back on my career in metal fabrication, I’m filled with a deep sense of pride and excitement for the future. The industry has come so far, and I’ve been honored to play a part in its evolution. But the true joy comes from the passion that drives us – the endless pursuit of perfection, the relentless pursuit of innovation, and the unwavering commitment to delivering world-class solutions for our clients.

So, what’s next for the world of metal shaping? I can only imagine the revolutionary breakthroughs that are just around the corner. Perhaps we’ll see the widespread adoption of advanced joining techniques like friction stir welding, or maybe we’ll witness the seamless integration of additive manufacturing into our traditional fabrication workflows. One thing is certain: The Weld Fab will be at the forefront of these advancements, constantly pushing the boundaries of what’s possible and delivering the precision, quality, and innovation that our clients have come to expect.

After all, in the ever-evolving landscape of metal fabrication, there’s always another challenge to conquer, another milestone to reach. And I, for one, can’t wait to see what the future holds.