As an experienced welder and metal fabricator, I’ve had the privilege of working with a wide range of materials and techniques over the years. One process that has particularly fascinated me is the art of weld overlay cladding. This versatile technique has become a vital tool in numerous industries, from oil and gas to power generation and shipbuilding, where corrosion and wear resistance are paramount.

The Power of Weld Overlay Cladding

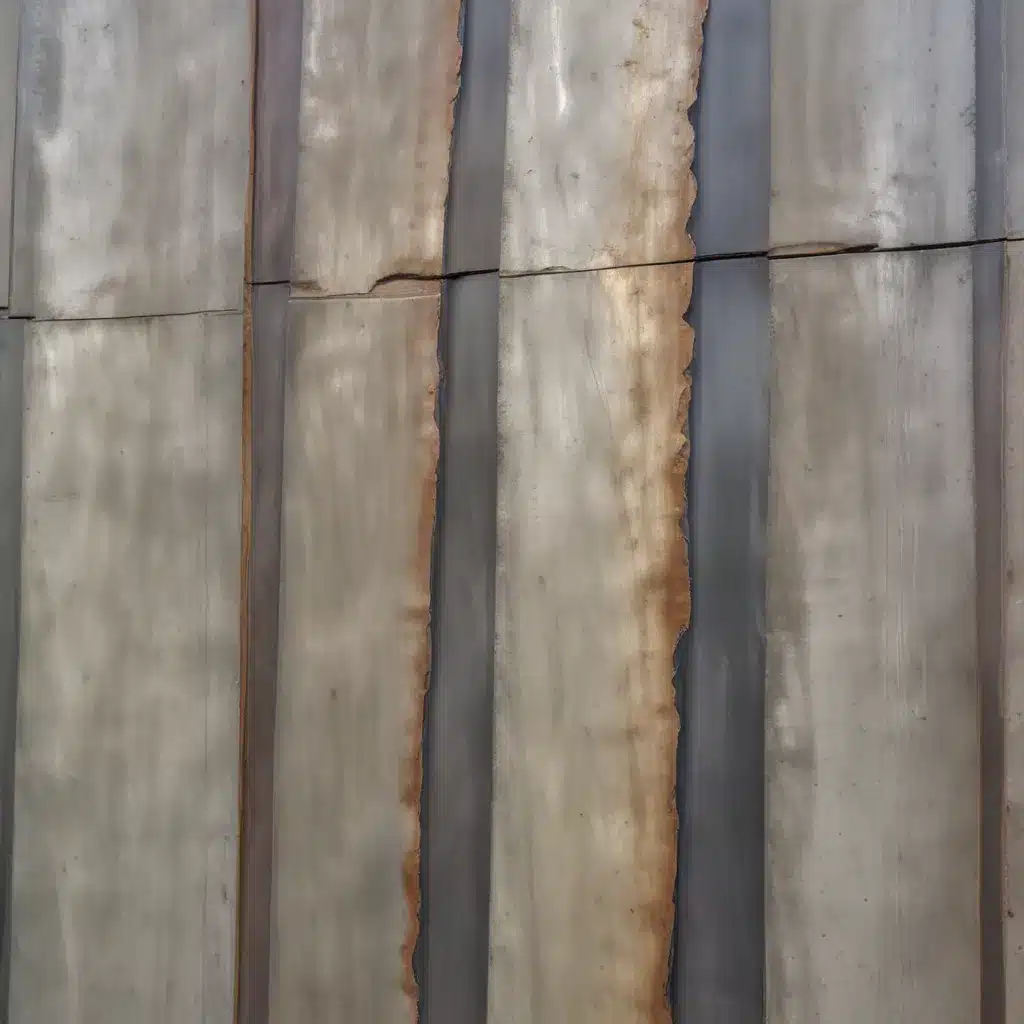

Weld overlay cladding involves depositing a layer of corrosion-resistant or wear-resistant metal onto a less expensive base metal using arc-welding processes. This cost-effective solution excels in three key areas:

-

Complex Shapes: Weld overlay cladding tackles intricate geometries with ease, making it the ideal choice for components with non-standard shapes. Whether it’s a manifold, a pressure vessel, or a custom-fabricated part, the versatility of this technique allows us to create robust and durable solutions.

-

Field Service: Overlay welding shines in on-site repairs and maintenance, offering the flexibility needed for field applications. When equipment needs to be repaired or refurbished without being removed from service, weld overlay cladding provides a reliable and efficient solution.

-

Heavy-Wall Vessels: For pressure vessels and reactors with thick walls, overlay welding offers a robust solution that protects the underlying base metal from corrosion and wear. This is especially crucial in industries where safety and integrity are paramount.

Mastering the Weld Overlay Cladding Process

As with any welding or fabrication technique, mastering the art of weld overlay cladding requires a deep understanding of the process and the factors that influence its success. Let me share some of the key insights I’ve gained over the years:

Dilution and Corrosion Resistance

One of the critical considerations in weld overlay cladding is the dilution of the cladding metal with the base metal. During the process, some of the base metal melts and mixes with the cladding material, which can affect the final corrosion resistance.

To mitigate this challenge, we need to carefully control the welding parameters, such as heat input, travel speed, and weld bead overlap. By optimizing these variables, we can minimize the dilution and ensure that the cladding layer maintains its intended corrosion-resistant properties.

Additionally, it’s essential to select the appropriate cladding material based on the specific corrosive environment the component will be exposed to. Stainless steels, nickel alloys, and other specialized alloys can be used to provide the necessary level of protection.

Distortion Management

As the weld metal cools and contracts, it can cause distortion, especially when the base metal is thin. This can be a significant challenge, particularly in applications where precise dimensions and tolerances are crucial.

To address this issue, we employ a range of techniques, including careful heat management, strategic weld sequencing, and the use of fixtures or backing plates. By controlling the thermal stresses and ensuring the component maintains its intended shape, we can minimize distortion and deliver a high-quality finished product.

Metallurgical Compatibility

Weld overlay cladding is generally limited to joining similar metals, primarily stainless steels and nickel alloys to steel. This is due to the need for metallurgical compatibility between the cladding and base materials.

When working with dissimilar metal combinations, alternative joining techniques, such as explosion welding or diffusion bonding, may be necessary. These specialized processes require a deep understanding of metallurgy and extensive experience to ensure a successful and reliable joint.

Space and Labor Considerations

Setting up a weld overlay cladding process requires a substantial amount of floor space for the necessary equipment, including the welding machine, positioners, and any automated or semi-automated systems. This can be a significant factor in workshop or facility design, as the available space and layout must be carefully considered.

Additionally, weld overlay cladding is a labor-intensive process that demands highly skilled welders. Investing in the training and development of our team is crucial to ensure consistent quality and maintain a competitive edge in the industry.

The Art of Weld Overlay Cladding in Action

One of the most rewarding aspects of my work as a welder and fabricator is seeing the transformative power of weld overlay cladding in action. I vividly remember a project we undertook for a major oil and gas company, where we were tasked with refurbishing a set of subsea manifolds.

These manifolds had been subjected to years of harsh subsea conditions, and the base metal was showing signs of severe corrosion. Using our weld overlay cladding expertise, we were able to deposit a durable layer of nickel alloy onto the corroded surfaces, effectively restoring the manifolds to their original condition.

The challenge was not only in the complexity of the component’s shape but also in the need to perform the welding work in a controlled environment on the job site. Our team of skilled welders employed specialized techniques and equipment to ensure a consistent, high-quality cladding layer, all while adhering to the strict safety protocols required for offshore operations.

The end result was a set of manifolds that not only looked brand new but also boasted enhanced corrosion resistance, extending their service life and saving the client significant time and resources. It was a testament to the power of weld overlay cladding and the dedication of our fabrication team.

Embracing Innovation and Continuous Improvement

As the industry continues to evolve, we at The Weld Fab strive to stay at the forefront of welding and fabrication technology. We’re constantly exploring new techniques, materials, and equipment that can enhance the efficiency, precision, and quality of our weld overlay cladding processes.

One area that has piqued our interest is the integration of automated and semi-automated welding systems. By leveraging the latest advancements in robotics and digital control systems, we can improve consistency, reduce labor-intensive tasks, and optimize the use of our valuable floor space.

Additionally, we’re exploring the potential of innovative cladding materials, such as advanced ceramic and composite coatings, to expand the range of applications and further enhance the corrosion and wear resistance of our fabricated components.

Conclusion

As an experienced welder and metal fabricator, I’ve come to appreciate the profound impact that weld overlay cladding can have on the success and longevity of critical components across various industries. From intricate manifolds to heavy-wall pressure vessels, this versatile technique has proven time and time again to be a reliable and cost-effective solution for protecting against corrosion and wear.

By mastering the art of weld overlay cladding,我们 at The Weld Fab are able to deliver exceptional results for our clients, helping them navigate the complex challenges of their industries with confidence. As we continue to push the boundaries of innovation and embrace the latest advancements in welding and fabrication, I’m excited to see what the future holds for this transformative technology.

Remember, when it comes to protecting your most valuable assets, weld overlay cladding is a true game-changer. So, if you’re facing corrosion or wear-related challenges, I invite you to explore the power of this remarkable process and experience the difference it can make for your business.