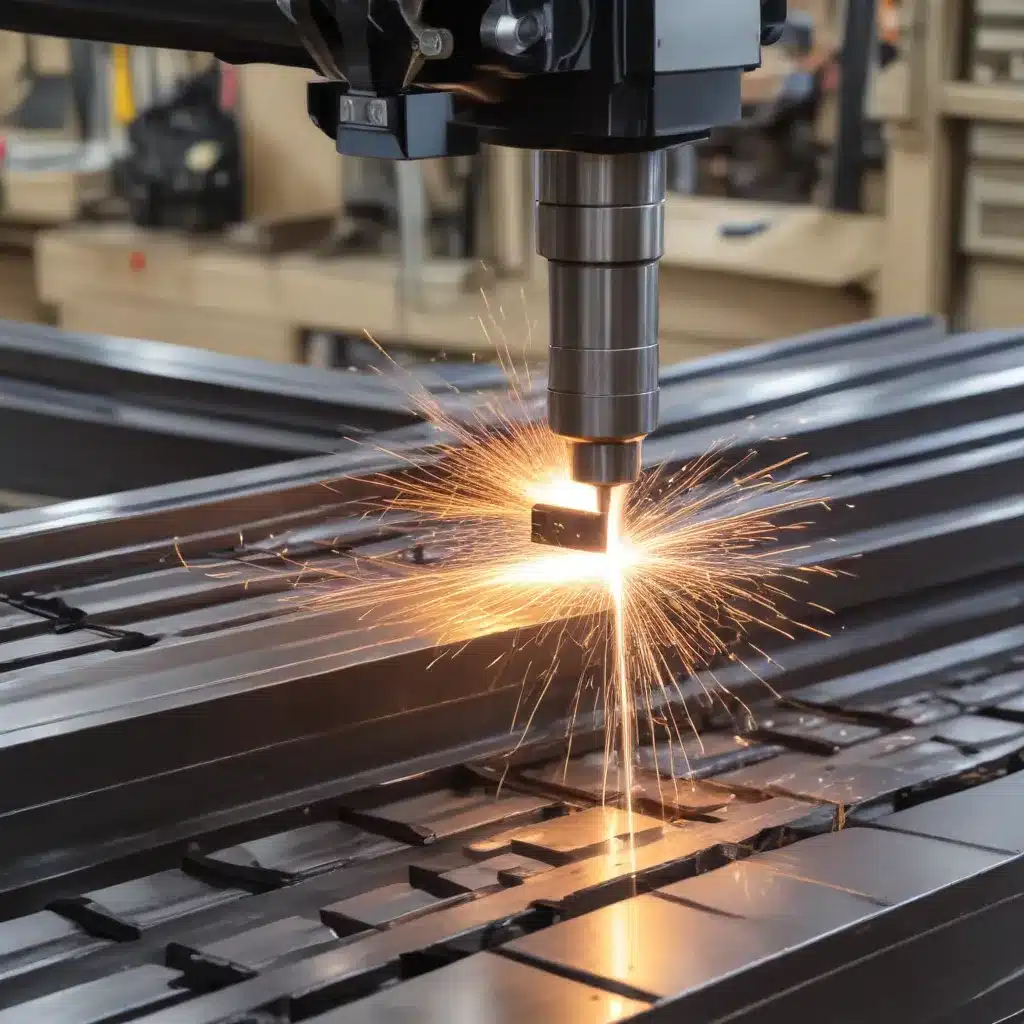

As an experienced welder and metal fabricator, I’ve had the privilege of working with some of the most advanced tools and techniques in the industry. But one technology that has truly revolutionized the way we approach structural steel fabrication is the power of CNC machining.

In my line of work, precision is paramount. We’re not just slapping pieces of metal together – we’re crafting intricate, load-bearing structures that need to withstand the rigors of everyday use. That’s why I’m so excited to share my insights on how CNC machining has unlocked a new level of quality and efficiency in our fabrication processes.

Let me take you on a journey through the world of CNC-driven structural steel fabrication, where the boundaries of what’s possible are constantly being pushed. We’ll explore the key benefits of this technology, delve into the techniques that elevate our craft, and uncover the ways in which it has transformed the industry as a whole.

The Precision Advantage: CNC Machining for Structural Steel

As a welder, I’ve always been obsessed with achieving the perfect bead, the seamless joint, the flawless finish. But when it comes to structural steel fabrication, precision is more than just a point of pride – it’s a critical factor in ensuring the safety and integrity of the final product.

That’s where CNC machining really shines. The level of accuracy and repeatability it offers is simply unmatched by traditional fabrication methods. With computer-controlled cutting, drilling, and finishing operations, we can consistently produce components that fit together like a well-oiled machine. Gone are the days of relying on manual measurements and eyeballing the alignment – CNC takes the guesswork out of the equation.

I remember a recent project where we were tasked with fabricating a complex support structure for a large-scale industrial facility. The design called for a series of intricate beams and columns that needed to be meticulously aligned to withstand heavy loads. Using our state-of-the-art CNC equipment, we were able to machine each individual piece with unparalleled precision, ensuring a seamless assembly that exceeded the client’s expectations.

The benefits of this level of accuracy extend far beyond just the initial fabrication process. When you’re dealing with structural steel, even the slightest deviation can have serious consequences down the line. With CNC-machined components, we can have confidence that the final product will perform as intended, reducing the risk of costly failures or safety hazards.

Streamlining the Fabrication Workflow

But precision isn’t the only advantage that CNC machining brings to the table. It also has a profound impact on the overall efficiency and productivity of our fabrication workflows.

One of the key aspects is the speed and flexibility of the CNC process. Gone are the days of painstakingly laying out and marking each individual cut or hole. With the right programming, our CNC machines can execute complex machining operations in a fraction of the time it would take us to do it manually. This not only reduces the overall labor hours required but also allows us to take on more projects and meet tighter deadlines.

I remember a time when we had a critical infrastructure project with a lightning-fast turnaround. The client needed a series of heavy-duty steel supports fabricated and installed in a matter of weeks. Using our CNC capabilities, we were able to streamline the entire process, from design to final assembly. The result? We delivered the completed project ahead of schedule, earning the client’s trust and opening the door to future collaborations.

But the benefits of CNC machining go beyond just speed. The versatility of these tools also allows us to adapt to changing requirements and specifications on the fly. With the ability to quickly reprogram our machines, we can pivot and adjust our fabrication plans as needed, without having to start from scratch. This kind of agility is invaluable in an industry where project parameters can shift rapidly.

Elevating Quality and Consistency

Of course, the real magic of CNC machining lies in its ability to consistently deliver high-quality fabrication results. As I mentioned earlier, precision is the name of the game, and our CNC equipment is unparalleled in its ability to meet the exacting standards demanded by the structural steel industry.

One of the key factors that sets CNC-driven fabrication apart is the level of quality control it enables. With each operation meticulously programmed and executed, we can ensure that every component we produce meets the strictest tolerances. Gone are the days of relying on individual technicians to manually measure and mark every cut or hole – the CNC machines handle it all with unwavering precision.

But it’s not just about the accuracy of the individual parts. CNC machining also allows us to maintain an unprecedented level of consistency across an entire project or even an entire product line. When you’re dealing with critical infrastructure like bridges, buildings, or industrial equipment, consistency is paramount. You can’t have one support beam that’s perfectly aligned and another that’s slightly off – it just won’t work.

That’s where the power of CNC really shines. By leveraging advanced computer controls and meticulously calibrated equipment, we can produce components that are virtually indistinguishable from one another. This level of consistency not only ensures the structural integrity of the final product but also streamlines the installation and assembly process, reducing the risk of costly errors or delays.

Unlocking the Full Potential of Structural Steel Fabrication

As someone who’s been in the welding and fabrication game for years, I can say with confidence that CNC machining has truly unlocked a new frontier in the world of structural steel fabrication. The precision, efficiency, and quality control it offers have transformed the way we approach even the most complex projects.

But the real beauty of this technology lies in the way it empowers us as fabricators to push the boundaries of what’s possible. With CNC, we’re no longer limited by the constraints of manual processes or the inherent variability of human-driven operations. Instead, we can focus on constantly refining our techniques, exploring new design possibilities, and delivering truly innovative solutions for our clients.

I’ve seen firsthand how CNC machining has allowed us to tackle challenges that would have been unthinkable just a decade ago. From intricate steel lattice structures to custom-engineered support systems, the sheer versatility of these tools is astounding. And as the technology continues to evolve, I can only imagine the even more impressive feats of fabrication that will be possible in the years to come.

So, if you’re a fellow welder or metal fabricator, I encourage you to embrace the power of CNC machining and see how it can elevate your craft to new heights. Unlock the full potential of structural steel fabrication, and together, let’s push the boundaries of what’s possible. After all, that’s what The Weld Fab is all about – using the latest tools and techniques to create truly extraordinary metalwork.