Mastering the Art of Precision Welding

As an experienced welder and metal fabricator, I take great pride in the work I do. Welding is not just a skill – it’s a craft that requires a keen eye, steady hands, and an unwavering commitment to quality. Over the years, I’ve had the privilege of honing my craft, pushing the boundaries of what’s possible and exploring the latest advancements in welding technology.

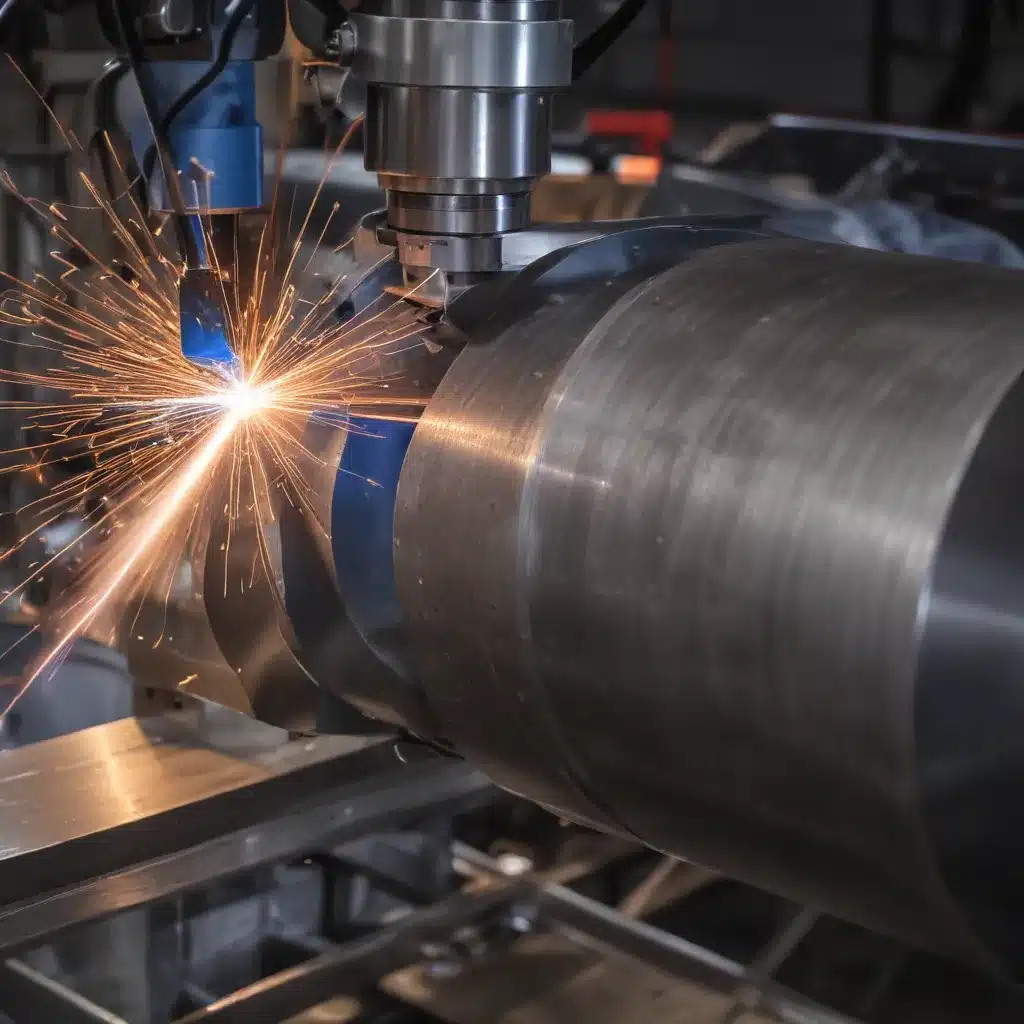

One of the most exciting developments in our industry is the rise of pulsed laser beam welding techniques. These state-of-the-art methods are revolutionizing the way we approach weld integrity and achieving unprecedented levels of precision and control. In this article, I’ll share my personal experiences and insights on how pulsed laser welding is taking the welding and fabrication world by storm.

Pulsed Laser Welding: A Game-Changer in Fabrication

When it comes to welding, the ability to precisely control heat input and heat distribution is paramount. Traditional welding methods, such as arc welding, can be tricky to master, as they often rely on the welder’s experience and intuition to achieve the perfect weld. However, with pulsed laser welding, the game has changed.

The key advantage of pulsed laser welding lies in its ability to deliver concentrated, high-intensity energy in a series of short bursts. This pulsed approach allows for exceptional control over the heat input, ensuring that the weld zone is heated and cooled in a carefully orchestrated manner. By fine-tuning the pulse duration, frequency, and energy, we can achieve an unparalleled level of precision, minimizing the risk of distortion, cracking, or other weld defects.

One of the most remarkable aspects of pulsed laser welding is its versatility. Whether we’re working with thin-gauge materials or thicker sections, this technology adapts seamlessly, allowing us to tackle a wide range of fabrication challenges with confidence. The focused beam and precise heat input mean that we can weld delicate components with surgical precision, while still maintaining the strength and integrity of the joint.

Unlocking the Secrets of Weld Quality

As a seasoned welder, I’ve always been passionate about understanding the science behind the process. With pulsed laser welding, the level of control and insight we have into the weld formation is truly remarkable.

Take, for example, the concept of heat-affected zone (HAZ) management. In traditional welding methods, the HAZ – the area surrounding the weld that experiences thermal changes – can be a source of concern, as it can lead to microstructural changes and potentially weaken the overall joint. However, with pulsed laser welding, we can significantly reduce the size and impact of the HAZ, ensuring that the base material retains its original properties and strength.

Another key factor in weld quality is the control of weld bead geometry. In the past, achieving a consistent, uniform weld bead profile could be a challenge, especially when working with complex geometries or thin materials. But with pulsed laser welding, we can dial in the parameters to produce beautifully consistent welds, time after time. The result? Joints that not only look aesthetically pleasing but also boast superior mechanical properties and fatigue resistance.

Pushing the Boundaries of Fabrication

One of the most exciting aspects of pulsed laser welding is its ability to push the boundaries of what’s possible in fabrication. As we continue to explore the full potential of this technology, I’ve had the privilege of working on some truly remarkable projects.

Take, for instance, the intricate stainless-steel components we fabricated for a cutting-edge medical device. The delicate nature of the parts and the need for exceptional precision meant that traditional welding methods simply wouldn’t cut it. But with pulsed laser welding, we were able to create flawless, seamless joints that not only met the stringent design requirements but also exceeded the client’s expectations.

Another project that stands out in my mind is the fabrication of a high-performance racing chassis. Here, the combination of strength, lightweight, and aerodynamic considerations made pulsed laser welding the ideal choice. By carefully controlling the heat input and minimizing distortion, we were able to produce a frame that was both incredibly strong and remarkably lightweight – a true testament to the power of this technology.

Embracing the Future of Welding

As I reflect on my experiences with pulsed laser welding, I can’t help but feel excited about the future of our industry. This technology is not just a passing fad; it’s a game-changing advancement that is redefining the standards of quality, precision, and efficiency in welding and fabrication.

I’ve had the privilege of working with some of the most innovative minds in the field, and the advancements we’ve seen in just the past few years have been truly remarkable. From improved beam delivery systems to advanced monitoring and control algorithms, the ongoing refinement of pulsed laser welding is pushing the boundaries of what’s possible.

But it’s not just the technical advancements that excite me – it’s the opportunity to push the boundaries of what we can create. With pulsed laser welding, the possibilities are endless. Whether we’re fabricating high-performance components, intricate architectural structures, or mission-critical industrial equipment, this technology empowers us to bring our wildest visions to life.

Embracing the Future with Confidence

As I look to the future, I can’t help but feel a sense of excitement and pride in our profession. The welding and fabrication industry is undergoing a transformation, and pulsed laser welding is at the forefront of this revolution. By embracing this technology and continuing to push the boundaries of what’s possible, we can elevate the quality, precision, and efficiency of our work to new heights.

So, what does the future hold for us? I see a world where weld integrity is uncompromised, where the limits of fabrication are constantly pushed, and where the satisfaction of a job well done is amplified by the knowledge that we’re at the forefront of a technological revolution. It’s a future that excites me, and one that I’m proud to be a part of.

If you’re a fellow welder or fabricator, I encourage you to explore the world of pulsed laser welding. Discover the power of this technology for yourself, and witness the transformation it can bring to your work. And if you’re a client or customer, I invite you to connect with The Weld Fab and let us show you the incredible possibilities that pulsed laser welding has to offer. Together, let’s forge a future where the art of welding and the precision of fabrication converge to create something truly extraordinary.