As an experienced welder and metal fabricator, I’ve had the privilege of working with a wide range of welding techniques and equipment. But one method that’s truly captured my attention in recent years is laser-assisted cold metal transfer (CMT) welding. This innovative approach has revolutionized the way we approach welding, and I’m excited to share my insights on how it can benefit your fabrication projects.

The Evolution of Welding: From Tradition to Innovation

When I first started out in this industry, I learned the fundamentals of welding the old-fashioned way – with a good ol’ stick welder and a lot of elbow grease. And let me tell you, those early days were tough. The heat, the sparks, the constant need for precision – it was enough to make even the most seasoned fabricator break a sweat. But as technology advanced, new welding methods emerged, each one promising to make our lives a little easier.

One of the most significant breakthroughs in recent years has been the introduction of laser-assisted CMT welding. This technique combines the precision of laser welding with the versatility of cold metal transfer, resulting in a powerful and efficient solution for a wide range of fabrication needs. And let me tell you, once you start using it, you’ll never want to go back to the old ways.

Laser-Assisted Cold Metal Transfer: A Marriage of Precision and Flexibility

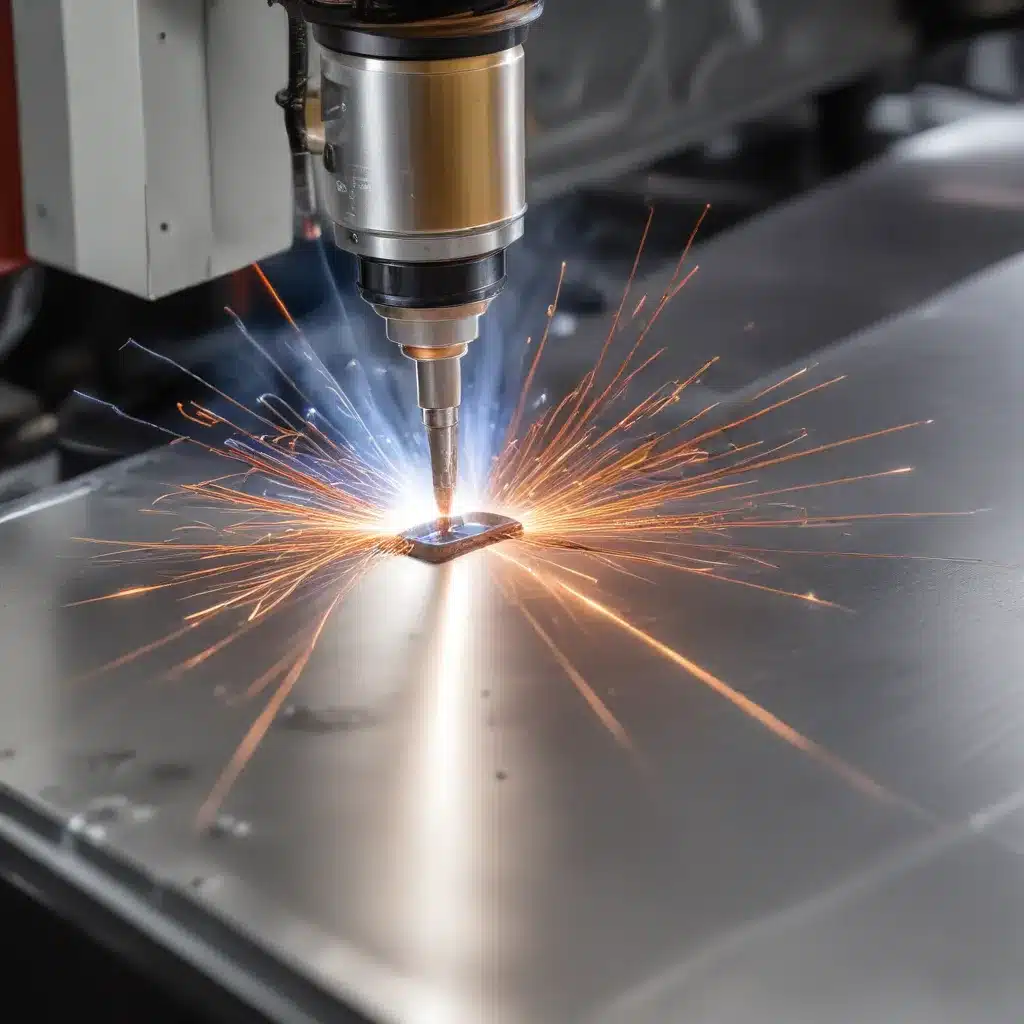

The key to the success of laser-assisted CMT welding lies in its ability to harness the best of both worlds. On one hand, you have the laser – a focused, high-energy beam that can melt and fuse metal with incredible precision. This allows for incredibly clean, consistent welds, even on thin materials or in tight spaces. And on the other hand, you have the cold metal transfer process, which uses a carefully controlled wire feed to deposit the filler material, minimizing heat input and distortion.

The combination of these two technologies is what really sets laser-assisted CMT welding apart. By using the laser to preheat the material and initiate the weld, the cold metal transfer process can then take over, depositing the filler metal with pinpoint accuracy and significantly reducing the overall heat input. This results in welds that are incredibly strong, yet with minimal distortion and a smooth, uniform appearance.

But the benefits of this welding technique don’t stop there. One of the things I love most about laser-assisted CMT is its versatility. Whether you’re working with thin, delicate materials or thick, heavy-duty components, this method can handle it all. And because the heat input is so low, it’s particularly well-suited for welding materials that are prone to distortion or cracking, like aluminum or high-strength steels.

Precision, Productivity, and Perfection: The Advantages of Laser-Assisted CMT Welding

As a welder and fabricator, I’ve always been obsessed with precision. And that’s precisely why I’m such a big proponent of laser-assisted CMT welding. The level of control and accuracy you can achieve with this technique is truly remarkable. Gone are the days of struggling with inconsistent welds or unsightly spatter – with laser-assisted CMT, every single weld is a work of art.

But it’s not just the quality of the welds that impresses me. This welding method is also incredibly efficient and productive. By minimizing the heat input and reducing the overall time required for each weld, laser-assisted CMT allows you to crank out high-quality fabrication projects at a breakneck pace. And let me tell you, in an industry where time is money, that’s a pretty big deal.

And the best part? Laser-assisted CMT welding isn’t just about the numbers – it’s also about the satisfaction of a job well done. There’s something incredibly rewarding about stepping back and admiring a flawless weld, knowing that you used the latest and greatest technology to achieve that level of precision. It’s a feeling that never gets old, no matter how many times I do it.

Overcoming the Challenges of Traditional Welding: How Laser-Assisted CMT Shines

Now, I know what you’re thinking – with all these fancy new technologies, there must be a catch, right? Well, I’m here to tell you that laser-assisted CMT welding is the real deal. Sure, there might be a bit of a learning curve, but once you get the hang of it, you’ll never look back.

One of the biggest challenges that traditional welding methods often face is the issue of heat-related distortion. Whether you’re working with thin materials or thick, heavy-duty components, the intense heat generated during the welding process can cause all sorts of headaches, from warping and bending to cracking and deformation. But with laser-assisted CMT, that’s a thing of the past.

By minimizing the overall heat input and precisely controlling the deposition of the filler material, this welding technique virtually eliminates the risk of distortion. And let me tell you, that’s a game-changer, especially when you’re working on critical, high-precision fabrication projects.

Another common issue with traditional welding is the dreaded porosity problem. You know the drill – you spend hours carefully positioning your workpiece, only to end up with a weld that’s riddled with unsightly holes and voids. Well, with laser-assisted CMT, those days are long gone. The controlled wire feed and precise heat input ensure that every weld is dense, uniform, and free of defects, no matter how complex the joint.

Embracing the Future of Welding: Investing in Laser-Assisted CMT Technology

Now, I know what you’re thinking – “This all sounds great, but isn’t laser-assisted CMT welding going to be crazy expensive?” And you know what? That’s a fair concern. This technology isn’t exactly cheap, and it does require a bit of an investment upfront.

But let me tell you, the long-term benefits far outweigh the initial cost. By investing in laser-assisted CMT welding, you’re not just getting a high-tech tool – you’re getting a game-changer that can transform the way you approach fabrication projects. From the incredible precision and consistency of the welds to the massive gains in productivity and efficiency, this technology is a true game-changer.

And let’s not forget about the all-important factor of customer satisfaction. When you’re able to deliver flawless, distortion-free welds with lightning-fast turnaround times, your clients are going to be over the moon. They’re going to see the value in your investment, and they’re going to keep coming back, time and time again.

So, if you’re serious about taking your welding and fabrication capabilities to the next level, it’s time to start seriously considering laser-assisted CMT welding. Trust me, it’s an investment that will pay dividends for years to come, both in terms of your bottom line and your reputation as a premier metal fabricator.

Embracing the Future: Unlocking the Full Potential of Laser-Assisted CMT Welding

As I wrap up this exploration of laser-assisted CMT welding, I can’t help but feel excited about the future of our industry. This technology is truly a game-changer, and I can’t wait to see how it continues to evolve and transform the way we approach welding and fabrication.

Just imagine the possibilities – the ability to weld the most complex, delicate components with unparalleled precision, all while dramatically increasing your productivity and efficiency. It’s the kind of technology that can truly revolutionize the way we work, and I for one, am ready to embrace it with open arms.

So, whether you’re a seasoned welder or a newcomer to the industry, I encourage you to take a closer look at laser-assisted CMT welding. Explore the capabilities, dive into the technical details, and see how it can benefit your business. Because trust me, once you experience the power and precision of this welding technique, you’ll never want to go back to the old ways.

Here at The Weld Fab, we’re always on the cutting edge of welding and fabrication technology, and laser-assisted CMT welding is just one example of the innovative solutions we offer. So, if you’re ready to take your welding and fabrication game to the next level, I invite you to connect with us and let’s explore how this amazing technology can transform your business.